AML3D announces supply of 3D printers and components

Additive manufacturing technology group AML3D has announced the successful supply of three of its large-scale metal 3D printers and continuing supply of additively manufactured components to industry.

The company said it had installed its Arcemy additive manufacturing centres at Royal Melbourne Institute of Technology, University of Queensland and the British Aerospace Australia, the latter being installed in the BAE Systems and Flinders University ‘Factory of the Future’ in Adelaide.

The Factory of the Future unit has already been profiled to representatives of defence contractors Thales, RheinMetall and Northrop Grumman.

Each of these three sales generated revenues of $400,000.

AML3D has also initiated supply of components for an Australian Tier 1 Oil and Gas company under the company’s agreement with AdditiveNow, having received an initial purchase order for $22,000.

The initial part will be exhaustively tested, with the company believing further parts will be ordered by the same customer.

Contract manufacturing was continuing with the production of pressure equipment parts for ThyssenKrupp and a major Australian energy company had been completed.

AML3D managing director Andrew Sales said: “We are pleased to report that the strong momentum in the business is translating to new purchase agreements and the continuing delivery of medium to large scale parts and components to Tier 1 customers.

“At the same time, we are continuing to progress discussions with multiple significant players in the Oil & Gas, Energy and Defence industries to supply industrial scale 3D metal printed components and secure repeat high volume orders.”

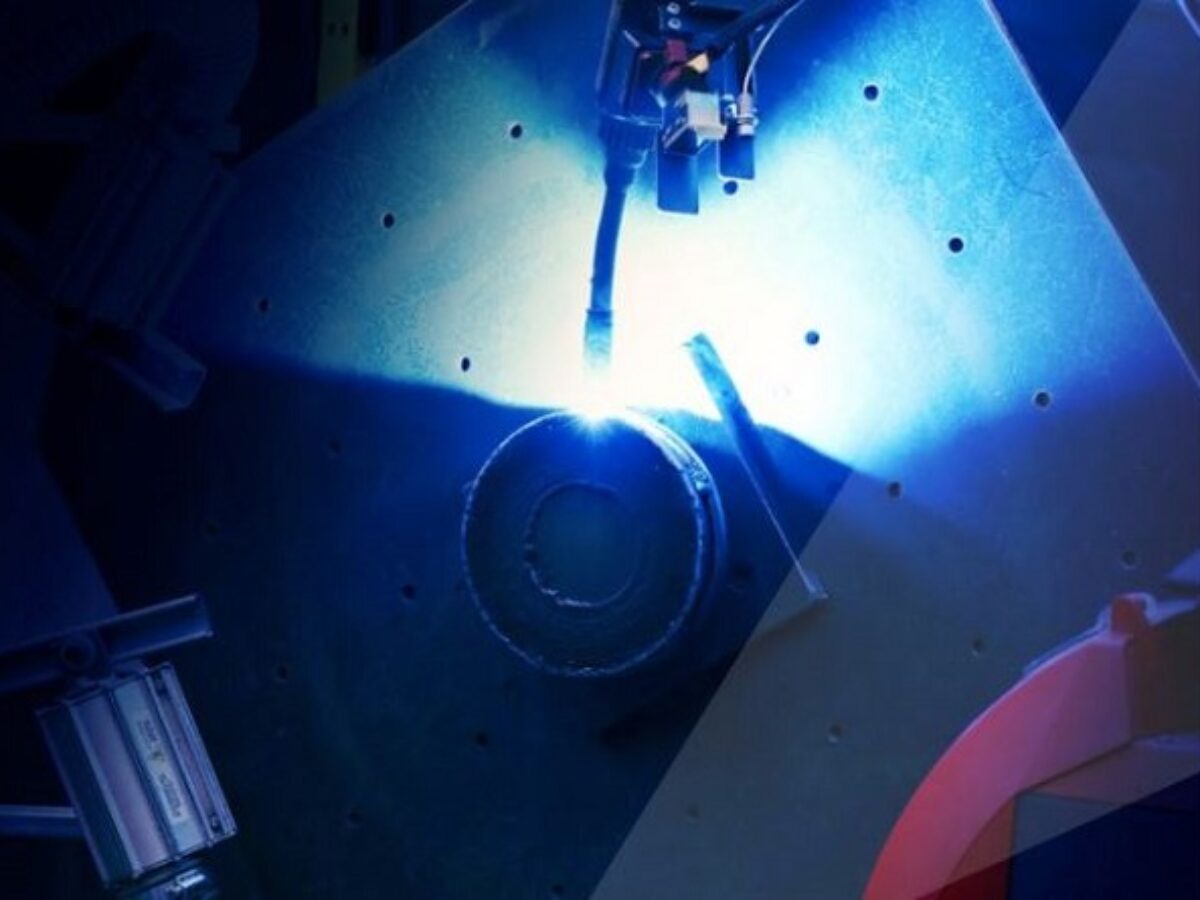

AML3D's Arcemy 3D printer utilises wire additive manufacturing technology to build up generally-large parts, including for heavy industry.

Sales said its products had received a positive reaction from customers in AML3D’s target sectors from attendees at the Indo Pacific Maritime conference in Sydney in May.

The company's Adelaide manufacturing facilities has also been inspected by Boeing’s Director of Global Additive Manufacturing for discussions on a scope of work for a high strength aluminium parts programme.

“These discussions are aligned with AML3D’s multi-phase growth strategy aimed at delivering short term value by winning orders in the Oil and Gas sector and, over the medium term, expanding into the Marine, Defence, Aerospace and Resources markets.

“Our success to date gives me confidence AML3D will deliver its guidance of over $2 million of revenues for FY22, a 200 percent increase over the prior year.”

AML3D has also completed the 3D metal printing of a high value high-value, nickel aluminium bronze, impellor for a major Australian energy company.

AML3D is now scoping the requirements for the supply of additional components and is generating a digital virtual library of the customer’s component inventory to support future orders.

Picture: AML3D

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos