An Australian alloy breakthrough, explained

Copper could be the key ingredient in improving titanium alloys for additive manufacturing. Brent Balinski spoke to RMIT’s Professor Mark Easton about recent work promising better printed parts.

Thursday featured news that Australian researchers had published results that could lead to higher productivity and fewer defects when additively manufacturing with titanium. By adding copper to titanium alloys, the team demonstrated printed specimens with “exceptional properties” due to a fine grain microstructure.

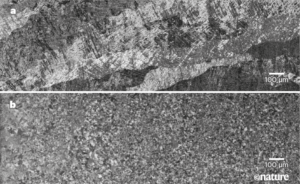

The paper in Nature, “Additive manufacturing of ultrafine-grained high-strength titanium alloys” detailed parts with “promising mechanical properties” and fine, equiaxed (equal in all dimensions) grains, rather than large, columnar (long and thin) grains, which can cause weaknesses and defects in printed objects.

Professor Mark Easton, one of the authors, has a background in light alloys, particularly around solidification processing.

He gives @AuManufacturing some context on the work, explains some of the advantages the alloys have over widely-used titanium-aluminium-vanadium blends, and discusses finding applications for industry.

The paper’s authors are Duyao Zhang, Dong Qiu, Mark A. Gibson, Yufeng Zheng, Hamish L. Fraser, David H. St John & Mark A. Easton, and it can be accessed here.

The interview is below.

@AuManufacturing: Please tell us something about what led to the paper. What prompted the research and the experiments?

Mark Easton: Firstly, grain refinement of alloys has been an active research area of mine since my PhD and one of the major issues in additive manufacturing has been the coarse columnar structure. Since we knew a lot about grain refinement we thought that we could use that knowledge to also produce fine grained alloys in additive manufacturing of Ti alloys, which has been very challenging up to now.

@AuManufacturing: Why are there no commercially available grain refiners for titanium alloys?

Large, columnar grains in Ti-6Al-4V (top) versus the finer titanium-copper grains. Both samples were printed under the same conditions.

(Picture: Nature)

Mark Easton: Ti alloys are technically very difficult to cast because of the very high temperatures and the reactivity of molten Ti which means that many compounds that may be used as grain refiners are unstable and also many compounds tend to dissolve in molten Ti-alloys. Because of this there is little Ti that is cast as most Ti is thermo-mechanically processed (e.g. rolled or forged) so there also has not been a lot of effort into controlling the solidified microstructures in Ti-based alloys compared with other systems.

@AuManufacturing: What are some advantages the new alloys have over Ti6Al4Va in additive manufacturing?

Mark Easton: The achievement of the fine grain structure means that the alloy mechanical properties are more uniform than Ti6Al4V. This may also mean that there have benefits in controlling shrinkage during solidification reducing defects such as cracks as distortion, although we have not investigated this in any detail as yet. Ti-Cu alloys have also been reported to have special anti-bacterial properties which may be useful in some biomedical applications. Cu is also about half the cost of Vanadium has lower embodied energy, and also Vanadium is on the is listed as one of the 27 critical raw materials by the European Union in terms of the supply risk and economic importance whilst copper is not. So there are some benefits here.

@AuManufacturing: Is this research something your team members are looking to patent?

Mark Easton: Possibly. Of course we cannot patent what has already been published but we believe that the publication is as much about an alloy design concept as a particular alloy system. The paper shows the possibility of moving beyond the commonly used Ti6Al4V alloy into very new alloy space with the possibility of much further improvements to be gained. So this paper is where the real possibilities begin. At RMIT, we focus on delivering to industry, and there is a great possibility of future partnerships leading to further new alloy recipes which are patentable technically and worthwhile financially.

@AuManufacturing: On a related note, please tell us about the potential commercial impact of this work? Is this likely to migrate into industry any time soon?

Mark Easton: My experience with alloy design and patenting over the years is that it is best to find an application for the alloy, develop the alloy with the properties and then consider patenting with the industry partner who you are working with. This process is time consuming and costly and it is critical that the industry partner drives the commercialisation process. We, as researchers, can provide the idea and prove the concept but the scale up needs to be driven by the material supplier and the end user. There are many reasons that a new alloy formulation may not make it to the market but the Ti-Cu system has many benefits including being relatively low cost, with good properties and metallurgy that is relatively well understood theoretically.

@AuManufacturing: Lastly, what are some challenges that came up as a result of the research, and will this lead to further work in the near-term?

Mark Easton: It is probably better to ask the question about the challenges that need to be considered to take this further. Improving the properties further by ternary alloying elements or heat treatments is the first step. We also need to consider the build of a component and the complexity associated with that including different thermal stresses and defect formation. A full assessment of properties would need to be considered as well. Also, there is the question of other alloy systems that have similar characteristics, where a similar design concept can be used which we are also investigating, which may show similar or better properties.

Featured picture: RMIT researchers involved in the multi-partner collaboration: Dr Dong Qiu, Professor Mark Easton and Dr Duyao Zhang (supplied)

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos