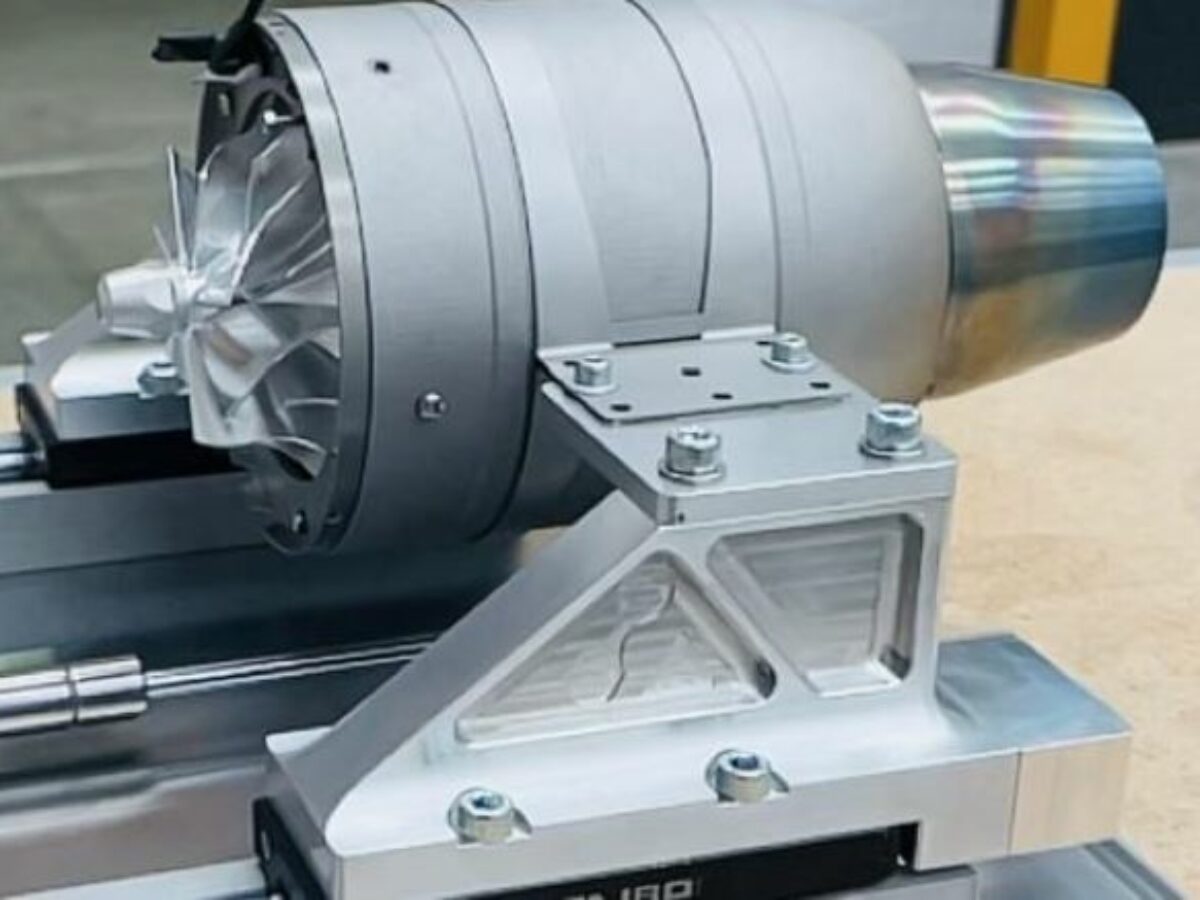

Aurora Labs 3D prints micro gas turbine

Aurora Labs has 3D printed a micro gas turbine that could be the centre of a small propulsion system or power plant for unmanned aerial vehicles or instant power generation.

The system, part of the company's development of 200N and 400N Class gas turbines, will be available in the market as early as next month and will run on natural gas or other liquid fuels.

CEO Rebekah Letheby said:” 3D metal printing has worked to its strength in accelerating the product prototyping process of A3D’s sovereign turbine engine.

“The team has manufactured an advanced product in under four months.

“The turbine engine design and printing has successfully met benchmarks for laboratory prototype testing, which is at the cutting edge of high energy 3D metal printing of components.”

Testing will now move to the field where the engine will be fitted to a remotely piloted airframe.

“It is our goal to have a cutting-edge piece of technology to sell to the sizeable

defence and aerospace markets.”

According to the company, the engine operates and compares in function and performance requirements to comparable engines built by traditional manufacturing methods.

The advantage with the A3D engine is fewer complex parts, that result in a fast and reliable assembly process, without compromising on performance.

“A3D has the 3D printing machines and expertise to carry out production runs of the engine, onshore in Australia.

“Efficiency and the weight of turbines are some of the key areas of A3D’s testing focus.

“These two items are linked in our turbine model by selecting individual parts which can be lightweighted through design, but also to select metal materials which ensure efficient material performance and allow for a reduction in overall mass.

“A lighter engine will benefit aircraft with improved fuel efficiency.”

In one section of the engine, the company took 18 parts and amalgamate them into one printed part, realising a 20 percent weight reduction on traditional engines of the same class.

Picture: Aurora Labs/3D printed micro gas turbine

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos