Australian researchers develop new acid-resistant zero-cement concrete

An RMIT team has developed a zero-cement concrete, made of recycled industrial by-products, which it says suffers almost no corrosion and could save on maintenance costs when used as sewage pipes.

The new composite blend is a “zero cement composite of nano-silica, fly-ash, slag and hydrated lime” and had exceeded strength requirements for sewage pipes set by ASTM International.

The mix avoids the use of free lime, a compound that led to corrosion and the forming of “fatbergs,” which are lumps of collected fat, oil, grease and non-biodegradable materials that clog pipes.

According to the researchers, led by Dr Rajeev Roychand, it could also endure the highly acid environment and was more durable than ordinary portland cement.

“Until now, there was a large research gap in developing eco-friendly material to protect sewers from corrosion and fatbergs,” Roychand said in a statement.

“Our zero-cement concrete achieves multiple benefits: it’s environmentally friendly, reduces concrete corrosion by 96% and totally eliminates residual lime that is instrumental in the formation of fatbergs… With further development, our zero-cement concrete could be made totally resistant to acid corrosion.”

The team is seeking industrial and government partners for development work.

Their paper “Development of zero cement composite for the protection of concrete sewage pipes from corrosion and fatbergs” can be read here.

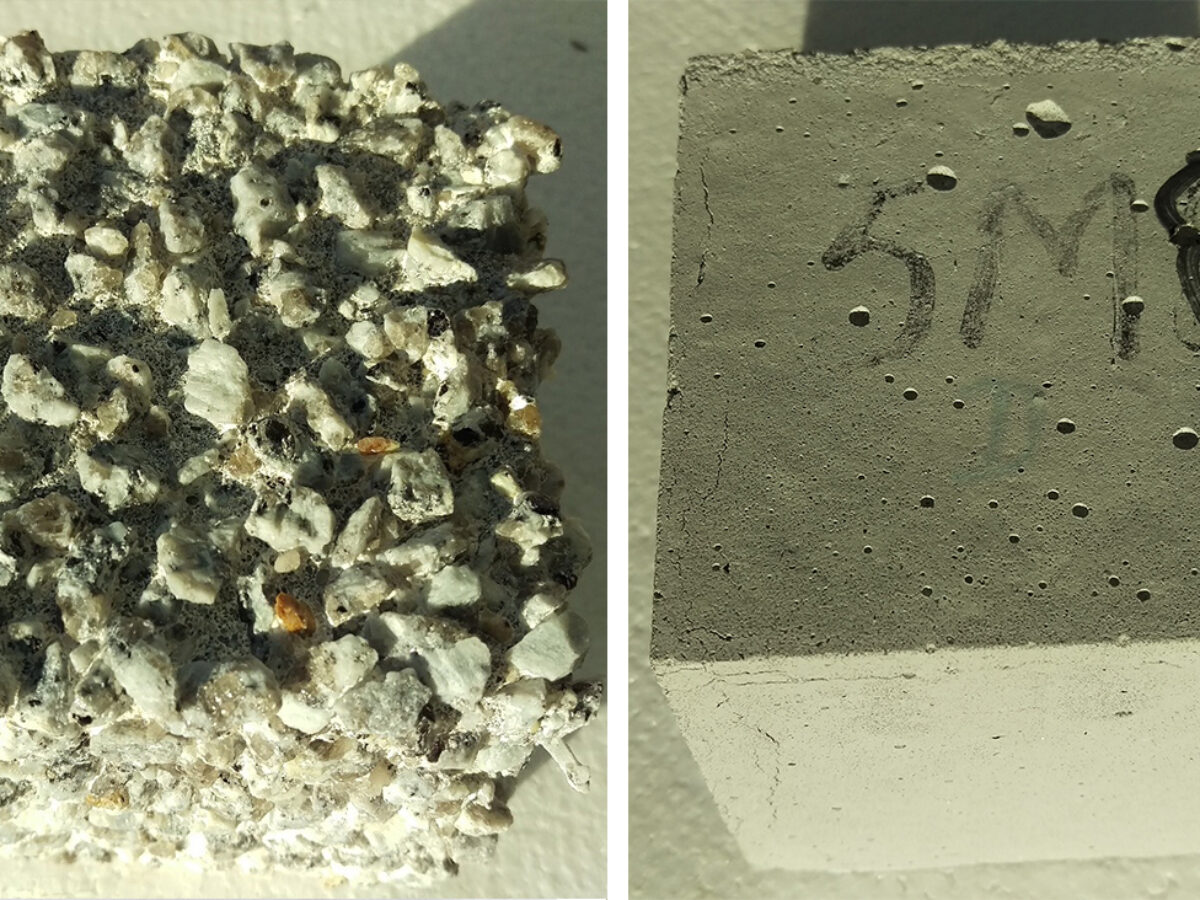

Picture: Left: Highly corroded ordinary Portland cement concrete. Right: Zero cement concrete. (RMIT)

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos