Australian researchers develop new quality control method for graphene manufacture

Monash University researchers have published results showing a way to identify high-quality graphene and graphene oxide much more easily than current methods.

According to the researchers — whose work is published in Advanced Science — the technique allows them to characterise graphene in liquid, which could greatly increase the quality and reliability of material produced.

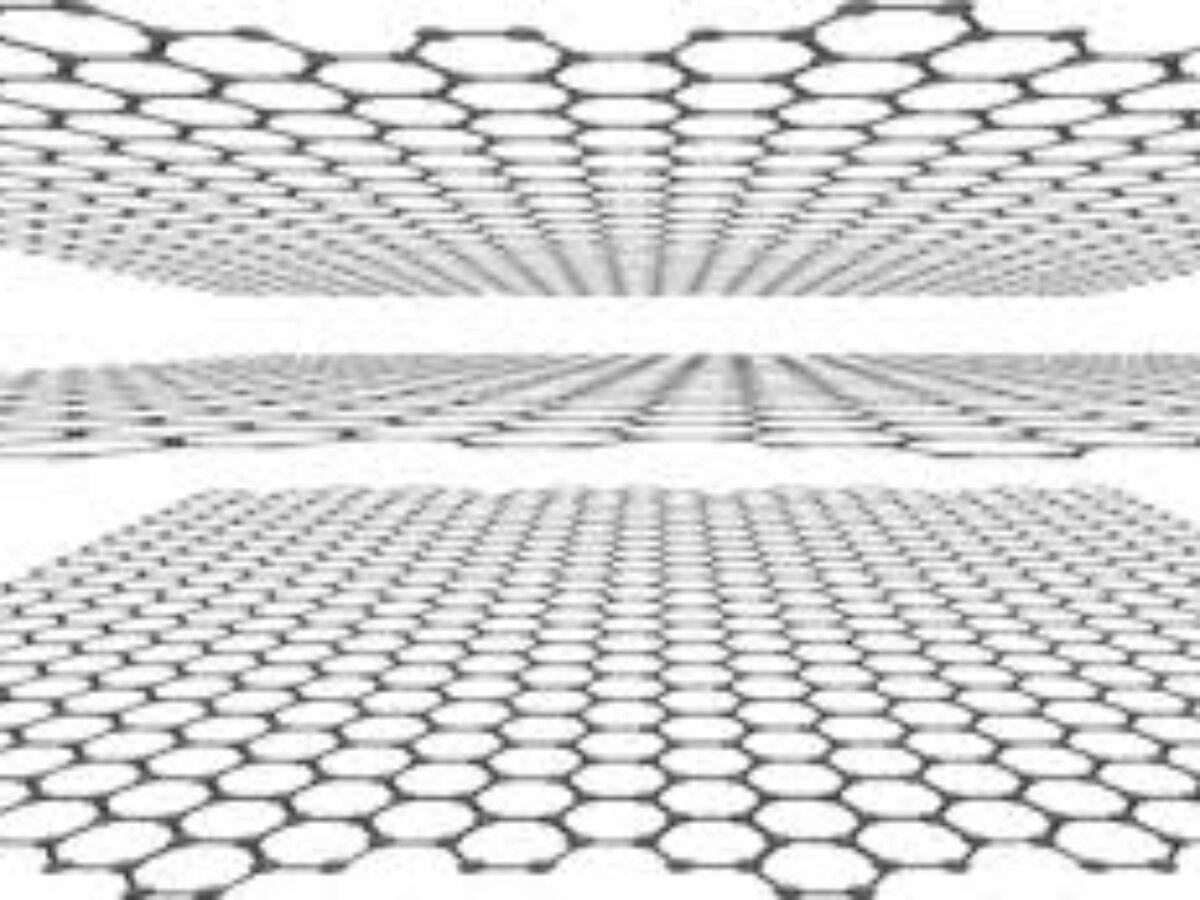

The most common way to manufacture graphene — an atom-thin layer of carbon atoms — is to exfoliate graphite in liquid, breaking it into 2D pieces. This requires a sample to be removed and characterised under a microscope to understand the quality of what it being made. The researchers' new technique uses a “quantitative polarised optical microscope” and a machine learning algorithm to “classify stacking at sub-nanometer to micrometer scale and measure the size, thickness, and concentration of exfoliation in generic dispersions.”

Graphene had remarkable electrical and thermal conductivity properties, and is widely used in industrial applications, said Professor Mainak Majumder of Monash, but remained expensive in bulk quantities.

“One gram of high quality graphene could cost as much as $1,000 AUD ($720 USD) a large percentage of it is due to the costly quality control process,” he said in a statement.

“Therefore, manufacturers need to be assured that they’re sourcing the highest quality graphene on the market. Our technology can detect the properties of graphene in under 14 minutes for a single dataset of 1936 x 1216 resolution. This will save manufacturers vital time and money, and establish a competitive advantage in a growing marketplace.”

Dr Mahdokht Shaibani said there had been a strong emphasis on standardisation for graphene materials, but monitoring during exfoliation and consistent quality across providers remained elusive.

“Discrepancies are often observed in the reported property-performance characteristics, even though the material is claimed to be graphene,” he said.

“Our work could be of importance to industries that are interested in delivering high quality graphene to their customers with reliable functionality and properties. There are a number of ASX listed companies attempting to enter this billion-dollar market, and this technology could accelerate this interest.”

The researchers said the technique also held potential to classify and quantify other 2D materials.

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos