Australia’s niche champions – Cochlear, the product that does good

In today's @AuManufacturing Australia’s niche champions series, Peter Roberts looks back at our most famous, and successful, niche player – hearing implant manufacturer Cochlear.

If you asked any Australian to name one of the country's global niche champions, chances are they would mention bionic ear manufacturer, Cochlear.

I followed Cochlear as a reporter from its earliest days, and looking back it is hard to believe that the Sydney company was not the world’s first to allow some types of deafness to be cured – and the miracle that the deaf could hear again.

That honour goes to the giant 3M company which Cochlear had to face and best in the market to become the world’s number one.

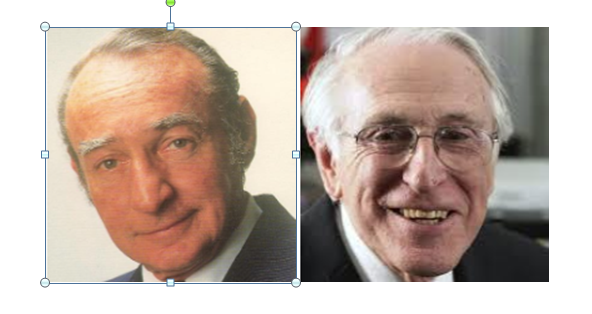

The company's success was the result of an extrordinary partnership between a brilliant scientist, Professor Graeme Clark (pictured below, at right) at the University of Melbourne, and an equally brilliant and determined entrepreneur, the late Paul Trainor (pictured below, at left).

Telectronics began making heart pacemakers in a room above a spaghetti shop in suburban Sydney in 1964, and by the 1980s, under Nucleus Ltd ownership, Trainor had grown the company to take 17 per cent of the world pacemaker market.

Trainor's business strategy was to use the cash flow from the pacemaker business to incubate a number of start ups, some of which faltered, but one of which was Cochlear.

Made up of an external speech processor and implant, Cochlear's device featured 22 electrodes sheathed in silicone and implanted on the cochlea nerve compared to 3M’s two electrodes.

Ultimately, far more information could be delivered by electrical stimulation at 22 spots compared to two.

But the other early success factor was the skill behind the software that converted speech picked up by a microphone into electrical signals, and how scientists coached early patients to learn to interpret those signals as speech.

Paul Trainor was a man with a tremendous heart, though also a calculating businessman.

He once took me with him to hospital to see a small child’s Cochlear implant switched on for the first time.

It was an overwhelmingly emotional experience – the look of joy on a little girl’s face when she hears her mother speak for the first time is a wondrous thing.

Trainor once told me that of his pride in the Cochlear implant as a product that ‘is good like a VCR, but also, unlike a mere recorder, does good too’.

One of Trainor's skills was recognising, hiring and nurturing great staff.

On a plant tour he once took me aside and, pointing to a newly hired accountant, whispered that ‘she was one to watch'.

She was Catherine Livingstone, who went on to be Cochlear's first CEO and and a successful career as chair of Telstra and the Commonwealth Bank.

But beyond the extraordinary people who made Cochlear, the final factor that grew Cochlear from nowhere to global leader was its excellence in manufacturing.

Cochlear implants are still assembled under a microscope at the company’s glittering factory cum campus at Macquarie University in Sydney, with implants sent to a small, sealed room for the key manufacturing process.

There, a laser welder runs round the outside of the titanium implant case, protecting the electronic components with a hermetic seal.

The Nucleus business was eventually sold to the Pacific Dunlop group in 1988 on Paul Trainor’s retirement, an early one forced on him by a family tragedy.

It was typical of Trainor that he gave away most of the fortune he made to his long serving staff.

Pacific Dunlop was then a shrinking conglomerate and their plans involved moving manufacturing of its Telectronics heart pacemakers from Sydney to the United States, where it had just bought the US-based Cordis pacemaker business.

Fortunately it left the much smaller Cochlear operation, and the key encapsulation process, in Sydney.

It was soon after that the Cordis manufacturing operation in the US began to experience manufacturing defects, which in the case of a heart pacemaker meant patients began suffering dangerous electric shocks.

More than a dozen were seriously impacted and the Cordis, and Pacific Dunlop medical business, evaporated overnight.

From this wreckage Cochlear and its factory were saved and floated on the ASX in 1995.

Cochlear is a worthy leader of Australia's niche champions with a global workforce of more than 4,000 people, turnover of $1.4 billion and annual investment of more than $180 million in research and development.

The company has manufactured more than 600,000 implantable devices, and it has never had issues with unexpected electrical discharges.

Picture: Paul Trainor, left, and Graeme Clark.

@AuManufacturing’s Australia’s niche champions series is brought to you with the support of the Innovative Manufacturing Cooperative Research Centre, and SMC Corporation.

Main picture: Cochlear Ltd

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos