Auto parts repairs revolutionised with 3D printing

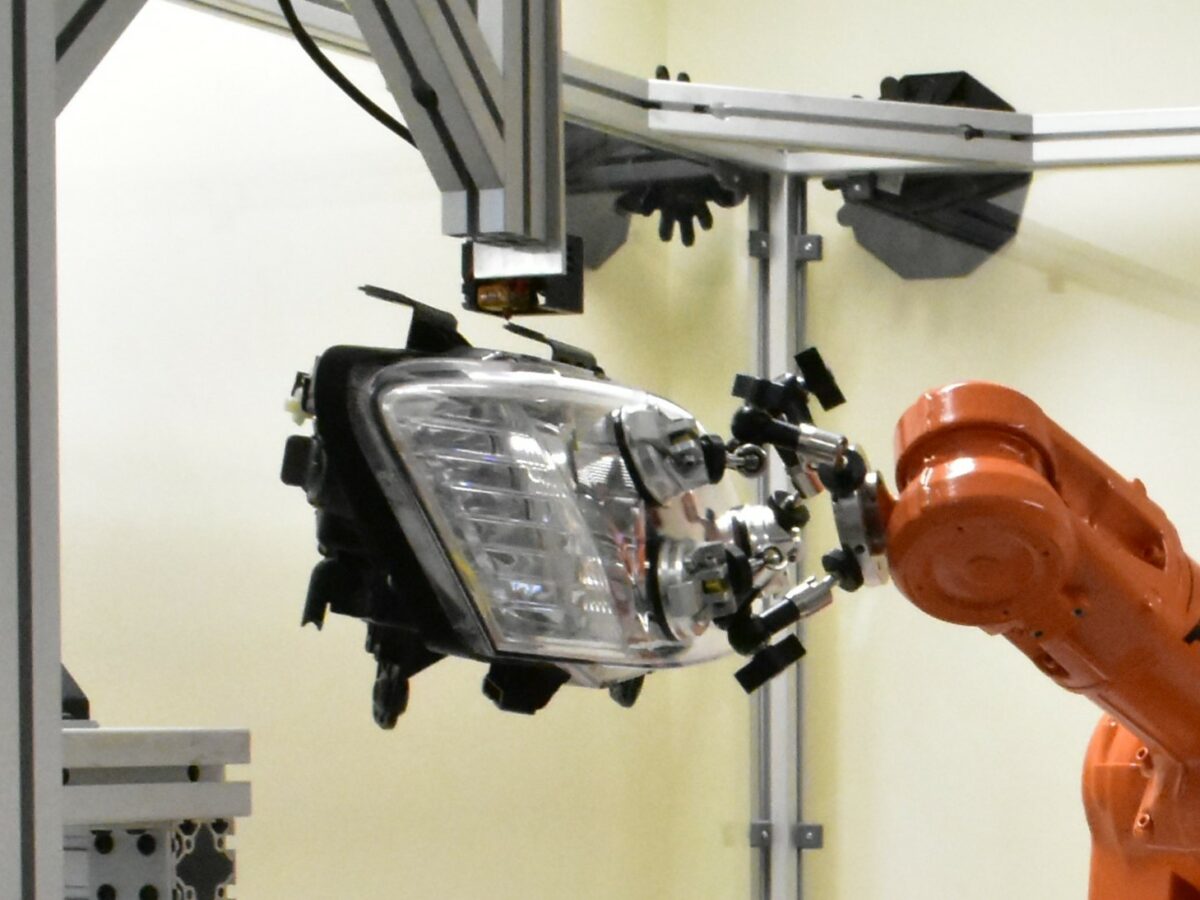

A joint industry-research 3D printing robot, Repairbot, has successfully repaired an automotive part using 3D printing techniques.

In a world-first, Repairbot 3D printed a replacement lug onto an automotive headlamp assembly as part of a project underway at Swinburne University.

An in-house formulated polypropylene composite material, developed by Swinburne’s materials scientist Dr Mostafa Nikzad, was used in the process.

The new material enabled the robotics team, led by Dr Mats Isaksson, to use a robotic arm to manipulate the headlight under a stationary 3D print head, allowing complex geometries to be printed without the need for support material.

The development by Swinburne is in collaboration with Tradiebot, which is developing industry 4.0 manufacturing, automotive aftermarket company, AMA Group, and the Innovative Manufacturing Cooperative Research Centre (IMCRC).

Tradiebot founder Mario Dimovski said: “The Repairbot will allow repairs to be conducted on damaged automotive plastic parts not currently repairable by technicians.

“The benefits will affect repair shops, consumers and flow on to the environment diverting these damaged parts from landfill. It’s a win, win for everyone.”

He pointed out the close collaboration between robotics experts and material scientists as the main contributor to the success.

“The truly cross-disciplinary nature of this project has made it possible to develop new materials and methodologies hand-in-hand with the novel robotic solutions,” Dr Isaksson said.

The development, which could significantly impact the automotive after-care market , is 18 months away from commercialisation.

David Chuter, CEO and Managing Director of IMCRC, congratulated the Repairbot team on reaching this significant project milestone.

He said: “The Repairbot project is a great example of industry and research collaboration.

“The researchers at Swinburne have wholeheartedly embraced Tradiebot’s idea of developing a technology-driven solution that will automate the repair service for automotive plastic parts.”

Picture: Swinburne University/Repairbot

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos