Bee-inspired biopolymer project will develop new textile coatings

Wellington, New Zealand-based biotech company Humble Bee Bio has been awarded a $70,000 grant to help develop a nature-inspired, water-repellent coating for textiles through a seven-month project with Deakin University.

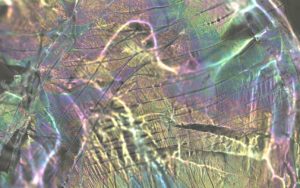

Raman image of Solitary Masked Bee nesting material (supplied)

The company was awarded a grant through the Innovative Manufacturing CRC’s activate program, supporting a project budgeted at $566,000 and delivering a formulation and production method for environmentally-friendly durable water repellent (DWR) coating.

DWRs are currently based on polyfluoroalkyl substances (PFAS), which are toxic. Humble Bee’s materials are safe and created with microbes using precision fermentation.

Humble Bee Bio’s CEO and Founder Veronica Harwood-Stevenson said their coatings were resistant to flames, high temperatures and strong chemicals.

“This research collaboration will enable Humble Bee Bio to take our proof of concept and develop a formulation and production method for sustainable DWR biopolymer coatings,” said Harwood-Stevenson.

“Australia is poised to become an advanced biomanufacturing centre of the world, and we are thrilled to be part of building that success.”

The company’s work is based on research from Victoria University of Wellington in NZ on a waterproof, cellophane-like substance that masked bees create to protect their nests and larvae.

Picture: Dr Dylan Hegh (right) and Professor Joselito Razal (supplied)

The project will be based at Deakin University’s Institute for Frontier Materials in Geelong with support from the Australian National Fabrication Facility.

Dr Dylan Hegh, IFM’s Circular Economy Initiatives Manager and the project’s lead, said that through refining the material’s formulation, the collaboration “has the potential to uncover new and unforeseen applications for the biopolymer and catalyse further research and development into advanced biomanufacturing.”

“Once commercialised, Humble Bee Bio’s sustainable DWR coatings have the potential to bridge a significant gap that exists within the textiles industry today,” added Dr Matthew Young, IMCRC’s Manufacturing Innovation Manager.

According to the company, the masked bee’s DNA offers up “a unique platform to engineer sustainable materials” that can be tailored in their properties and be applied in numerous markets, as well as be fully-biodegradable.

Main picture: A masked bee (Mark Berkery/Picasa)

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos