Carbon Revolution spins up wheel production

Composite wheel manufacturer Carbon Revolution has revved up production of its one piece carbon fibre road wheels at its Geelong factory despite the uncertainties of the Covid-19 pandemic.

The young company grew wheel sales 8.3 per cent in the March quarter as demand from its high-end global customers remained strong.

A new high annualised rate of production of 32,000 moulded wheels was achieved in March.

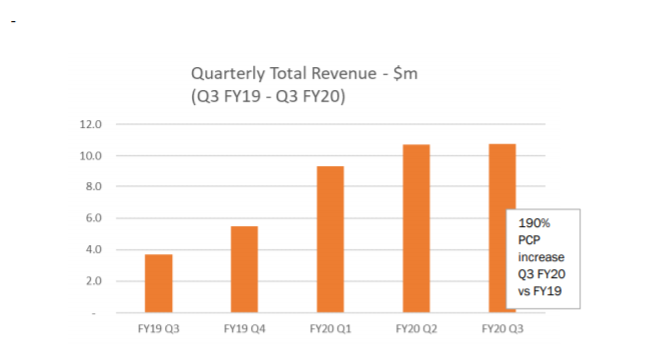

Production was up 184 per cent on the prior corresponding period and the company booked revenues of $10.8 million in the quarter (see graph, below).

CBR told investors: “The business has used this global shutdown to fast track the development and implementation of an industrial technology that improves wheel aesthetic quality.

“This area has represented an ongoing challenge for he business.

“The higher moulding rate had led to a short term increase in inventory of wheels in process, which together with this new technology enables a lift in the wheel sales rate through the remainder of the calendar year.”

Carbon Revolution has been industrialising its production systems as it moves from prototyping to start-up to full production mode.

Carbon Revolution has installed new cutting, lay up and rimming equipment and new tools have been acquired to increase machine usage.

The company is working on new wheel programmes with OEM manufacturers to add to its prestige customer list which includes Ford for the Mustang GT, Ferrari for the 488 SF90, and Renault for the Megane RS Trophy-R.

During the quarter the company raised $25 million from institutional investors and in April a further $2.7 million from existing shareholders through a share purchase plan.

The company has a positive cash balance of $48 million.

Picture: Advanced Fibre Cluster Geelong

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos