CSIRO and Japan’s Piotrek to develop new lithium batteries

A partnership between CSIRO, and Japanese chemical manufacturer, Piotrek, will develop Australian-developed battery technologies aiming for commercial production in the next five years.

The two will develop lithium battery technologies for portable electronic devices, drones and automotive vehicles, as well as developing batteries less prone to fires.

They will develop Solid Polymer Electrolytes (SPEs) for lithium batteries using CSIRO's Reversible Addition-Fragmentation chain Transfer (RAFT) polymer technology and Piotrek's Ion Conducting Polymers (ICP).

General Manager at Piotrek, Ihei Sada, said “This partnership will help Piotrek make our batteries safer and more efficient, and with our industry reach, we will get our advanced batteries to the market faster.

“Together we will develop the world's safest, longer life solid state high energy battery.”

Solid state batteries are a class of lithium batteries that typically use a lithium metal anode.

CSIRO researcher Adam Best, said there are proposals to have solid state battery enabled devices in the market by 2025.

Best said: “Our RAFT technology allows us to tune our SPEs' properties to expand their versatility for different types of batteries and fuel cells, and will also significantly reduce the cost of device assembly and manufacture.”

No mention was made in the organisation's media release of whether CSIRO would seek to have manufacturing located in Australia, or whether CSIRO would be merely a technology supplier earning a royalty to the Japanese company.

Director of CSIRO's Manufacturing arm Keith McLean, said the partnership will support productivity gains, boost sustainability and help capture emerging opportunities in local and global battery markets.

McLean said: “CSIRO is committed to solving the greatest challenges through innovative science and technology.

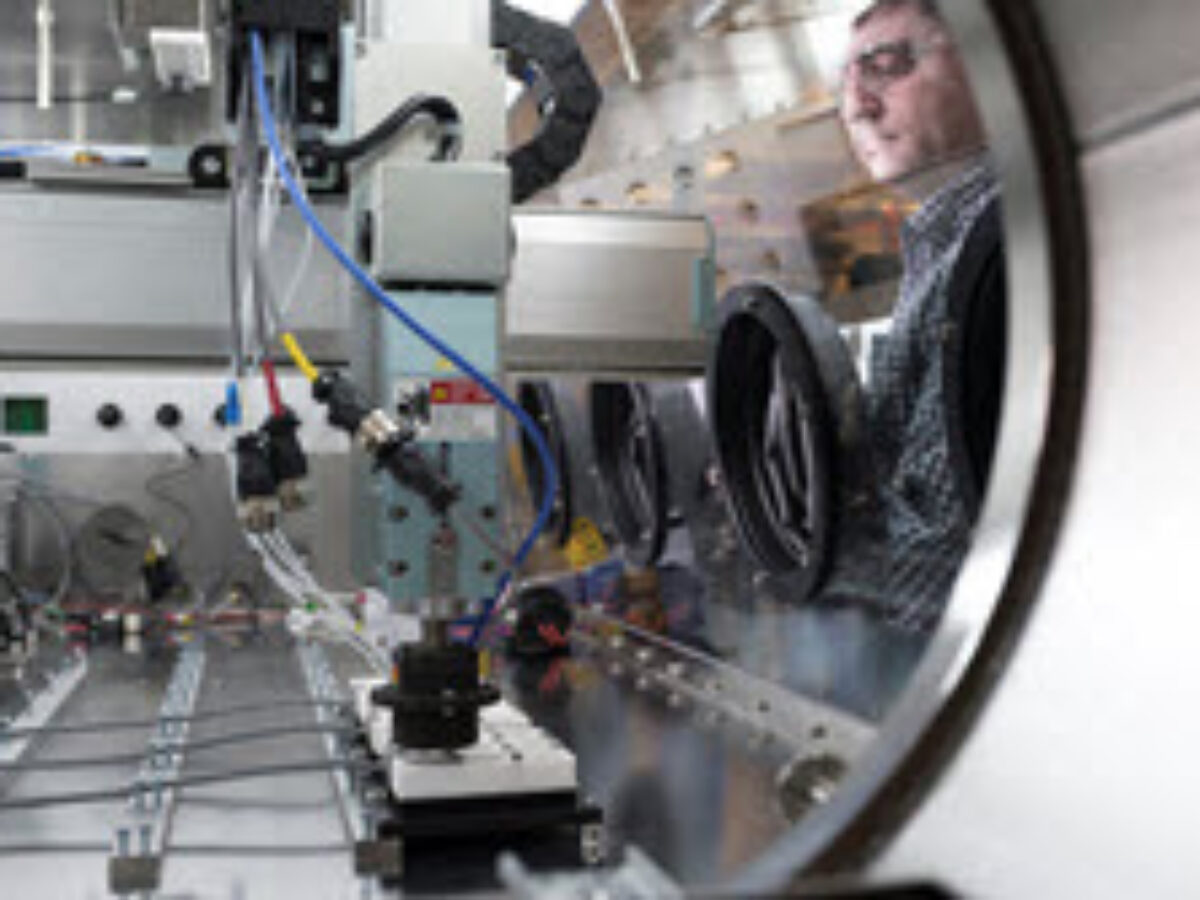

Picture: CSIRO

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos