Deakin and Ford create wool-based alternative to petrochemical car insulation

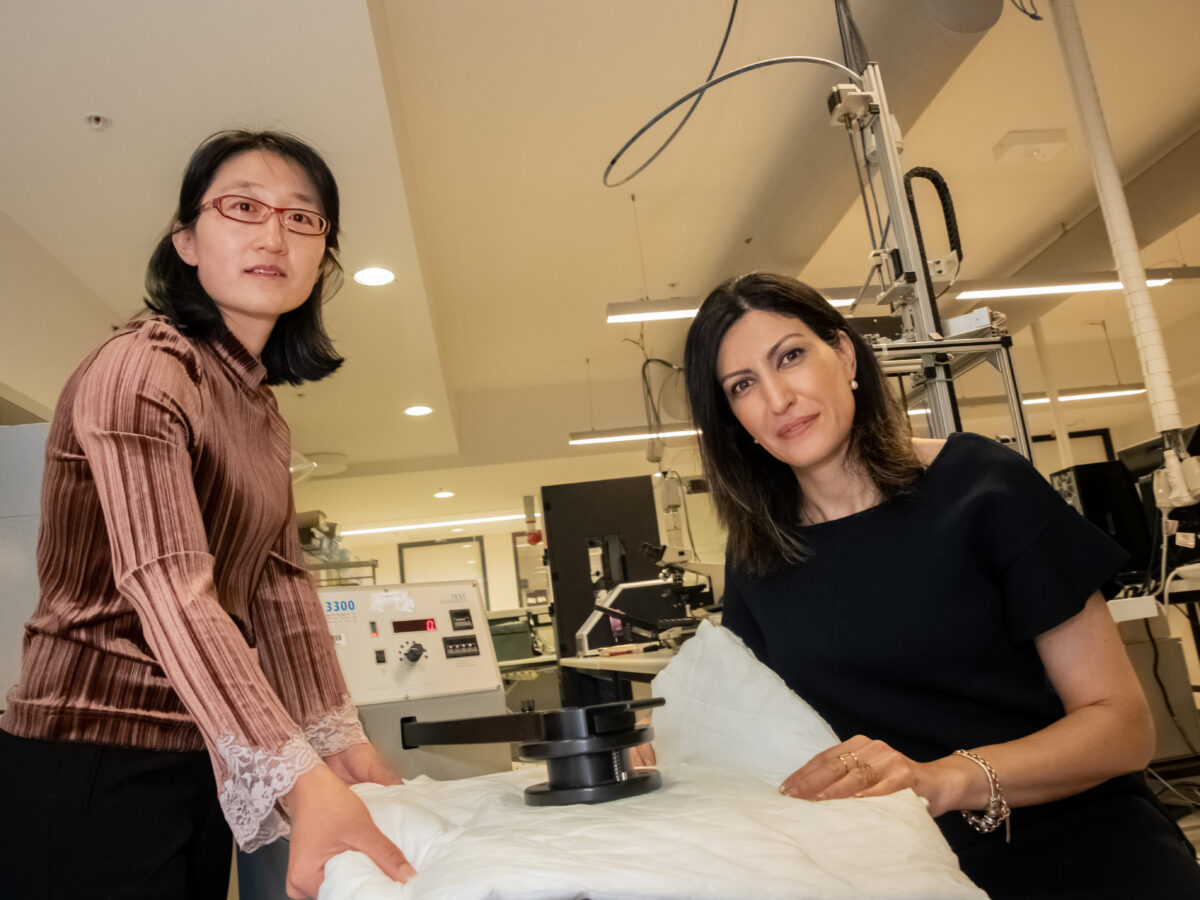

Researchers at Deakin University's Institute for Frontier Materials have worked with Ford to create a new wool-based insulation, which they say has environmental and other benefits over synthetic materials currently in use.

Led by Dr Maryam Naebe, IFM academics worked with Ford Motor Company researchers to engineer the new textiles, “using blended waste and virgin wool insulated fibres covered with a thin nonwoven fabric via needle-punching.”

Naebe said that car companies were moving towards lighter, natural fibre materials and away from polyester, polyethylene and polystyrene interiors.

“The majority of car insulators are currently made using petroleum-based microfibres, which aren’t sustainable, and contribute to ecological issues,” said Naebe.

“The automotive industry is in need of a high performance, cost-effective, low carbon footprint, and biodegradable alternative for insulation.”

According to Naebe, the final product has similar sound absorption, thermal resistance and air flow properties to what's being used currently, but with the added benefits of wool, such as odour-resistant, flame retardant and antibacterial properties.

“The project has been an example of great collaborative effort,” she said.

“Ford has a long relationship with Deakin, IFM, and the city of Geelong where our institute is based, so it’s great for our textile and fibre groups to have their support with

this project.”

Picture: Dr Zengxiao Cai and Dr Maryam Naebe in the Deakin IFM labs with the wool insulator material (supplied)

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos