Defence partnering for success – by Professor John Spoehr

Today @AuManufacturing continues our sponsored series reporting BAE Systems Australia's Partnering for success defence industry supplier event we look at burgeoning partnerships in naval ship construction. By Professor John Spoehr.

In much of life, success is the sum of a lot of parts. This is inherently true in the defence sphere.

Australia is embarking on a major expansion of capability, the like not seen since federation, and success will depend on intricate and finely tuned networks to deliver the right requirements to the right standard at the right time.

The scale and diversity of undertakings will test our nation’s supply chains.

Visionary organisations have been positioning in readiness to seize enormous opportunities in shipbuilding for the Hunter frigate and AUKUS submarine programmes, the joint strike fighter programme, and myriad other sea, air, and land initiatives.

Supply chains cannot be conveniently turned on and off like a tap. They’re the product of careful planning, of anticipating future need, developing skills, investing in uplift and achieving sustainable momentum.

The most successful supply chains include redundancy and can ride out peaks and troughs.

A crucial element is diversification, and developing systems that can be put to other applications.

Another crucial element is integration, ensuring interconnection between research, business, and industry domestically and globally, to maximise knowledge and minimise risk.

And underpinning it all is innovation, harnessing new ways to meet existing and emerging demand.

As the Director of the Australian Industrial Transformation Institute at Flinders University, building industry capability, supporting advanced manufacturing practice and embodying R&D into relationships between suppliers and industry is what I live and breathe.

We’re driving exciting developments at the Factory of the Future in the heart of Adelaide's Tonsley Innovation District, where in collaboration with BAE Systems Australia we’ve created a ‘like real world’ test bed enabling new technologies and construction methods to be tested and trialled at scale and transferred direct to the Hunter class frigate construction programme.

But success isn’t only about the ‘at scale’ stuff – small efficiencies can have a big impact.

Increased automation in SME’s will increase capability and provide opportunities for engagement in defence.

An example is our Manufacturing Growth Accelerator programme that will engage with more than 200 small and medium sized companies, bringing them together with researchers, students, and industry to not just drive technological advances but develop the aligned skills needed for advances to be utilised. This tackles the two-fold task of technology and the human factor.

Its remit will be further extended with the state government’s decision to co-locate the Tonsley Technical College with the Factory of the Future and provide secondary students with visible pathways to high tech jobs.

Collaboration will lift Australia’s capability

Whilst the Covid pandemic and border closure dramatically demonstrated weaknesses in sovereign capacity and capability, it has been a catalyst for change, bringing renewed vigour to domestic and international relationships to build strong networks that can withstand challenges.

Tonsley is an excellent example, and is a foundation member of the Global Institute on Innovation Districts.

The Flinders Factory of the Future and BAE have connected with the University of Strathclyde – operator of the National Manufacturing Institute of Scotland to establish the Advanced Manufacturing research exchange to open up prospects for the adoption of ground-breaking manufacturing technologies and processes.

We’ve also struck education and research agreements with the University of Manchester and University of Rhode Island to deliver the skills and expertise needed for the AUKUS programme. This in turn giving business confidence they’ll have the necessary skills available to participate in supply chains for this national building project.

Importantly we’re increasingly seeing these kinds of initiatives emerging and taking hold at other universities.

This underscores the importance of education and research in informing and supporting business and industry development, helping organisations to build their industry 4.0 capabilities through accredited and non-accredited education and training programmes, strengthening supply chains, and driving Australia’s economic and social advancement.

Further reading:

FLINDERS TO CATAPULT INDUSTRY INTO THE ADVANCED MANUFACTURING AGE

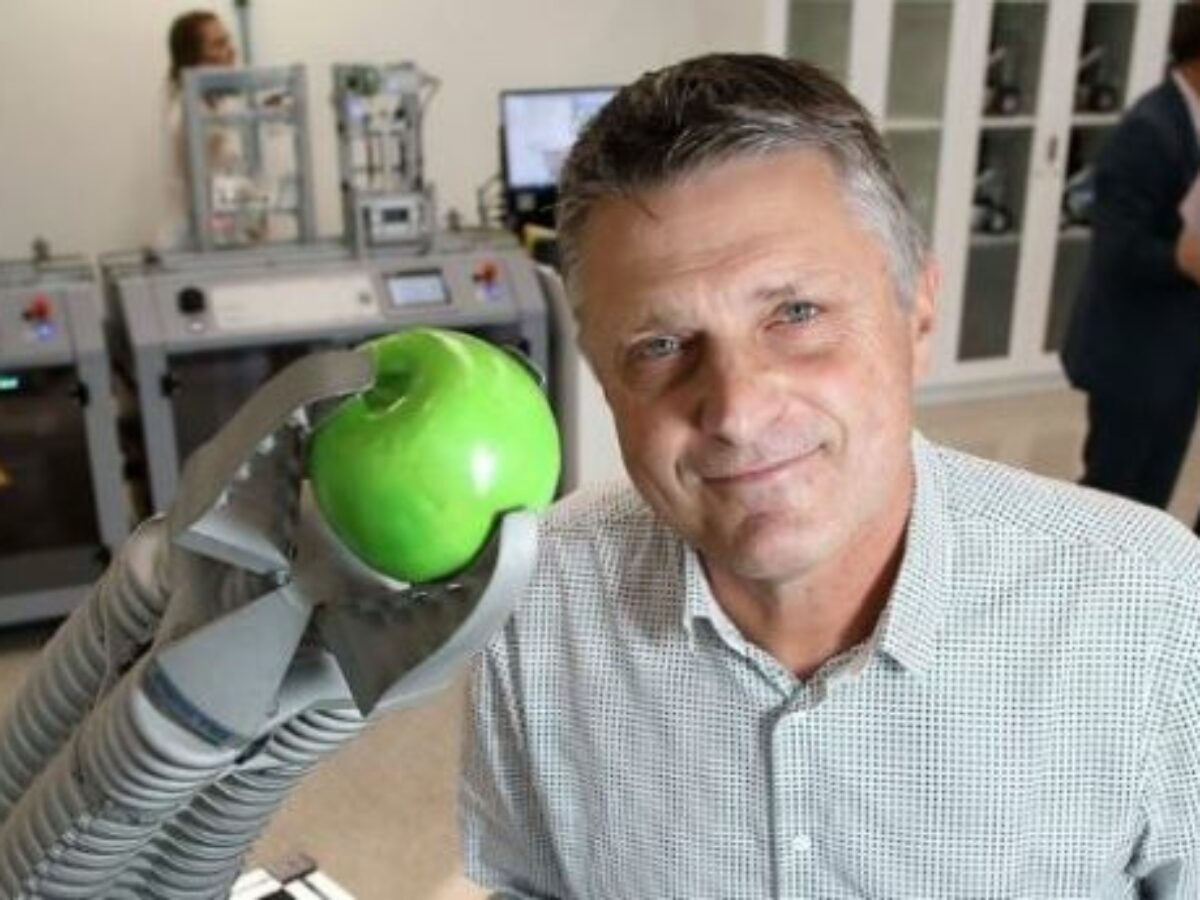

Picture: news.flinders.edu.au/John Spoehr at the Factory of the Future

Professor John Spoehr is Flinders University Pro Vice Chancellor Research Impact and Director of the Australian Industrial Transformation Institute.

@AuManufacturing's series Defence industry partnering for success is sponsored by defence sector prime contractor BAE Systems Australia.

![]()

Topics Analysis and Commentary Defence

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos