Dematec targets Hunter with connectivity technology

Leading technology being developed by South Australia's Dematec Automation could sit at the heart of the all-digital Osborne naval shipyard being established in Adelaide by BAE Systems Australia.

BAE Systems, which will deliver nine advanced anti-submarine frigates to the Royal Australian Navy, has collaborated with Dematec to build a digital platform capability demonstrator.

The demonstrator connects robots, welding machines, hardware sub-systems, devices and sensors across typical shipyard workflows, where Industry 4.0 technologies are connecting workers, robotic plant and equipment.

It has been established at the Line Zero – factory of the future industrial technologies testing facility in Adelaide’s Tonsley Innovation District that BAE Systems operates with Flinders University.

Dematec Automation director David Hart said: “BAE Systems’ focus is to make Osborne Naval Shipyard the world’s most technologically advanced shipyard, and our aspiration is that Dematec technology sits at the centre of a digital network that brings the precinct together.”

Early in 2021, Dematec was selected in BAE System’s first Innovation Challenge to create an integration platform capable of providing connectivity, visibility and historical data capture for production plant and equipment and their sub-systems.

A “track and trace” system is needed at the Osborne shipyard to provide a window on each step in the shipbuilding production process, providing the data needed for construction, future maintenance and continuous improvement of every element on a frigate.

At Tonsley, Dematec integrated its platform with collaborative robots, autonomous intelligent vehicles (AIVs), industrial sensors and industrial programmable logic controllers, each with a variety of industrial communication protocols.

Hart said: “Our track and trace system demonstrated the capabilities that can be integrated in a real-world system to provide real-time visibility of users, objects, machines, sensors, and events, as well as the historical data capture and recall for quality, compliance, and continuous improvement purposes.”

The integration platform operated both a ‘control centre’ as well as a ‘shop-floor operator’ style of application using iPads where teams could manage system access, drill down into the data being collected and monitor in real time.

“We believe this technology could play a key role in providing the connection between the industrial equipment and associated production sub-systems and the ‘higher level’ scheduling and maintenance software systems to be utilised in the shipyard.”

BAE Systems Australia continuous naval shipbuilding strategy director, Sharon Wilson said collaboration with industry and education organisations is crucial to drive industrial capability across the supply chain.

Wilson said: “Technology developed by Australian businesses is vital to help us delivering our digital shipyard, and Line Zero provides exposure for Australian innovation to industry – large and small – across defence and non-defence sectors.”

BAE Systems is committed to involving Australian SMEs in the construction of the frigates.

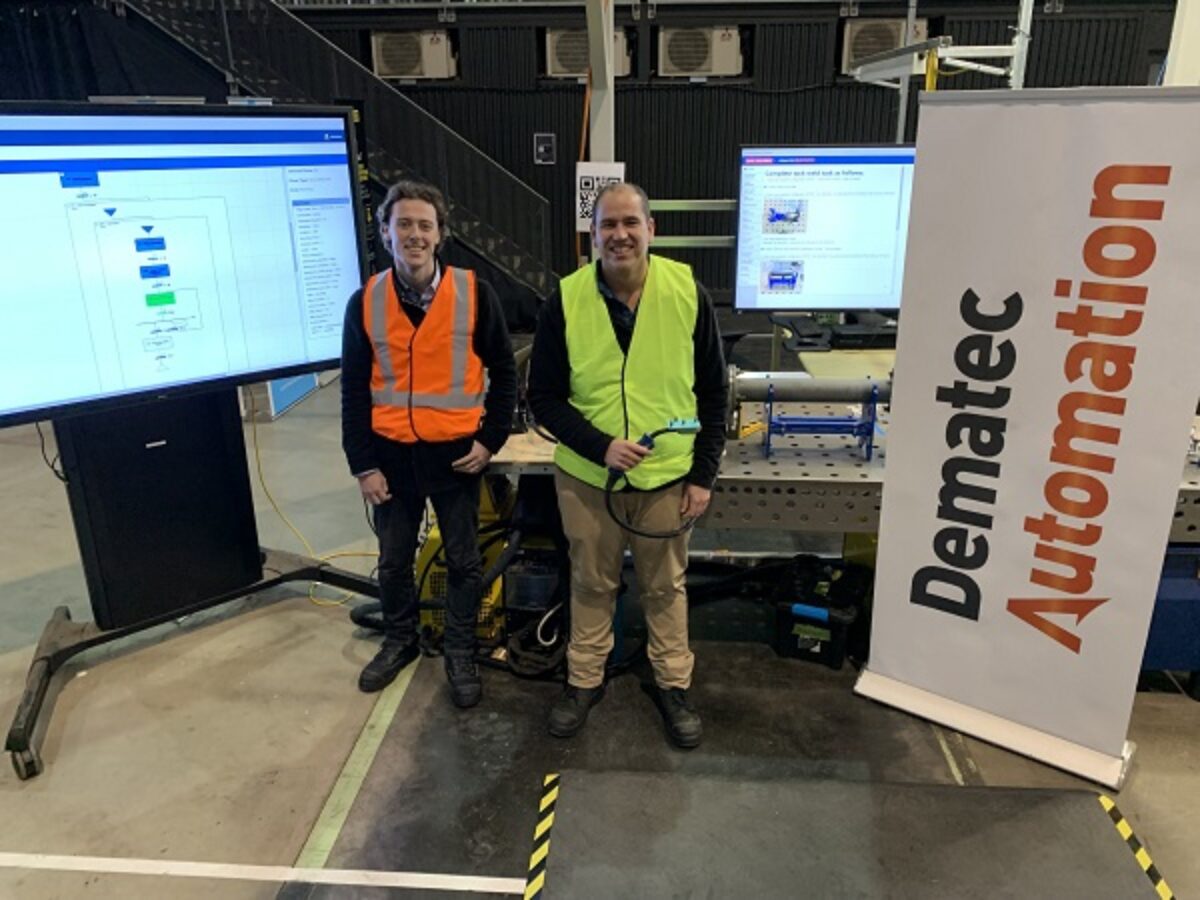

Picture: Johan Magnus and Christopher Balnaves from Dematec at the Line Zero – factory of the future

Subscribe to our free @AuManufacturing newsletter here.

Topics Defence

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos