Enabling design for environmental good reports examine what’s needed in circular economy shift

A series of reports released on Thursday outline a roadmap for Australia’s circular economy transition, which is still in its early stages, and highlight the importance of design in this.

Enabling Design for Environmental Good was commissioned by the federal Department of Climate Change, Energy, the Environment and Water.

RMIT project lead and Associate Professor Simon Lockrey said a central body run out of the federal government was needed to coordinate the circular transition.

“This call for a new and coordinated approach to designing sustainable products and industries is not a nice-to-have, but an urgent necessity,” said Lockrey in a statement.

“We need an approach that ties together the interests of the federal, state and local governments, which will help businesses and industry work towards a common goal.”

An estimated 70 per cent of a product’s environmental impacts over its lifecycle are decided at the design stage.

The reports (available here) make clear that the design responsibility is not only with designers, with decision makers in management, marketing and supply chains having the final say in enabling and commissioning design.

RMIT researchers led a consortium of experts, with consultants from Arcadis Australia and One Planet Consulting, to deliver the reports. They make ten recommendations covering products made and/or sold locally in four priority sectors – textiles, plastics, buildings and electronic goods. (These are reproduced below.)

“Australian industry sectors will become increasingly uncompetitive unless these recommended actions are taken to align with leading nations on better product design, sale and circularity,” said Helen Millicer, Churchill Fellow and Director of One Planet Consulting.

“Likewise, households and businesses will pay ever higher costs, and our environment too, if we continue our sad, excessive ‘throw-away’ systems of highly refined textiles, electronic goods, building products and plastics.”

The ten (10) cross-cutting levers (CCLs):

- Cross-cutting lever 1 (CCL1) – Adopting national Eco-Design for a Circular Australia Strategy

- Cross-cutting lever 2 (CCL2) – Revise and energise product stewardship and extended producer responsibility

- Cross-cutting lever 3 (CCL3) – Activate design for reuse, repair and refurbishment – the Reuse & Repair Reset program

- Cross-cutting lever 4 (CCL4) – Raise standards and specifications for products and materials for systematic national alignment with global best practice

- Cross-cutting lever 5 (CCL5) – National funding for Eco-Design and circular initiatives/ supply chain innovation – The Eco-Design Innovation Fund

- Cross-cutting lever 6 (CCL6) – Accelerating Recyclables from Landfill Fees on priority products

- Cross-cutting lever 7 (CCL7) – Mechanisms addressing externalities

- Cross-cutting lever 8 (CCL8) – Procurement power and market pull – the Buy for Good program

- Cross-cutting lever 9 (CCL9) – Professional education program to activate skills and capacity for environmental good – the Learning for Environmental Good and Upskilling Program

- Cross-cutting lever 10 (CCL10) – Accelerate public acceptance and support of design for environmental good

Disclosure: the Australian Manufacturing Forum was a participant in this project

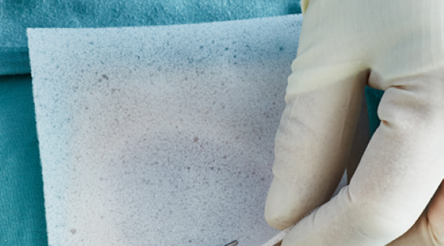

Picture: credit www.electronicrecyclingaustralia.com.a

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos