Entech in the van of electronics revival

By Peter Roberts

The 1980s and 1990s were optimistic times for electronics manufacturing in Australia, with changing technologies allowing new companies to establish such as Entech Electronics in Adelaide, GPC Electronics in western Sydney and IntelliDesign in Brisbane.

Like all manufacturing there have been ups and a lot of downs since then but the sector, surely the bedrock for any advanced manufacturing sector, is going through a period of growth as Australian companies have learned to exploit global supply chains and operate seamlessly internationally against the toughest of competition.

Entech is typical, preparing itself to move into a new 10,000 square metre factory at Salisbury South in Adelaide, doubling today’s manufacturing floor space, and premises it expects to outgrow in a few short years.

Entech has been growing at more than 20 percent a year manufacturing printed circuit boards, electro-mechanical assemblies and Human-Machine Interface (HMI) solutions for the IoT, Medical Devices, Communication, Industrial Electronics, AgTech, defence and mining sectors.

Its factories and 400 staff in Adelaide and Shenzen, China operate with identical software and production systems, so products can be seamlessly located where customers choose and where it makes the most sense.

CEO Wayne Hoffman said: “We hope to have (the new factory) on line by the end of April, but the big ticket item in terms of announcements I suppose is our venture into Malaysia.

“Our Singapore operation has been up there sourcing materials and setting up our supply chains for nearly three years.

“So that has set the scene for us to go into Malaysia doing box build, glue and screw as we affectionately call it, but also full service to the full supply chain from electronics, plastics, metalwork, hardware, wiring harnessing.”

Owned by its management, Entech’s new factory in Penang, Malaysia – Adelaide’s sister city – is already attracting work from South East Asian customers.

In fact mastery of global supply chains, giving customers in Australia and elsewhere access to global pricing is one of the strengths of the company. Another is focus.

While competitors, and Entech in the past, offer design and product development services, Entech has chosen to become a pure contract manufacturer, focusing on its relationships with design houses across the country.

Hoffman said: “We are not telling designers how to do their job – their job is design.

“Our job is to help them do the best they can. We see ourselves as enablers of designers and enablers of end product.”

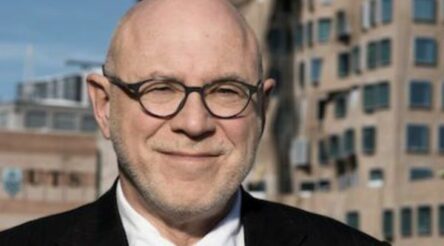

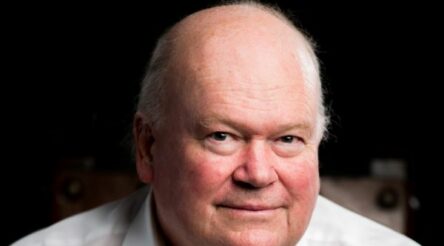

Picture: Entech Electronics/Wayne Hoffman and Susan Close, Deputy Premier and Minister for Industry, Innovation and Science, South Australia.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos