Fibres and composites transforming industry: Smart composites and coatings for radiation shielding

In a late addition to our Fibres and composites transforming industry series, Dr Nishar Hameed explains how graphene’s properties have seen it emerge as a candidate for electromagnetic interference shielding in composites.

Defence and space platforms are designed with compact, high-power electronics units, used very close together, which are sometimes developed by different manufacturers.

Electromagnetic interference (EMI) from electronic devices and components can result in various negative consequences, such as causing safety- and mission-critical systems to malfunction.

EMI shielding and radar-absorbing structures are essential in ensuring performance, interoperability, and safety.

EMI shielding materials also play a decisive role in securing confidential information, such as military and business secrets that need to be protected. As a result, various EMI standards have been developed, according to the MIL-STD-810, and so on.

Fibre-reinforced polymer composites are primarily used in aerospace and defence industries, among others, on account of their unique advantages. These include their light weight, chemical stability, versatile processing techniques, and robustness versus conventional metallic components.

One of the chief obstacles to the ever-increasing use of fibre-reinforced composites is typically the lack of inherent electromagnetic shielding capabilities required to prevent EMI affecting sensitive electronic components. Accordingly, there is a growing demand to develop broad-band shields able to neutralise electromagnetic radiation in the GHz range.

Recent scientific breakthroughs have shown that molecular sheets of sp2 bonded carbon, known as graphene, offer unique characteristics that make it a promising candidate to be used as EMI shield, including its high electrical conductivity and superior strength to weight ratio.

Naturally, the challenge then becomes utilising this nanomaterial’s properties through incorporating it into or onto a composite part, avoiding the need for metal grids, which ultimately yield high-performance carbon-based composites with multifunctional properties.

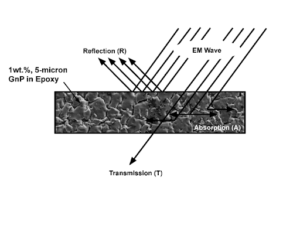

Graphene can be either integrated into the matrix of the composites (in-plate) or as a nanomaterial-based radiation absorbent skin coating (on-plate) to enhance shielding performance. Furthermore, the distribution and orientation of integrated graphene may be further manipulated to improve the EMI-shielding performance and decrease the filler loading.

A recent research finding from Swinburne University of Technology [https://doi.org/10.1016/j.cartre.2021.100047] revealed that the introduction of graphene nanoplatelets into composites offers multiple benefits, including their physical attributes such as enhanced reflectivity and selectivity in absorption in different parts of the electromagnetic spectrum, making them useful for enhanced radiation shielding applications. The work of the Swinburne team was an important contribution to a DMTC-managed collaboration involving a national network of research and industry partners.

In addition to creating a set of reproducible experimental data, the study facilitated numerical models to predict the composite properties. These findings are then employed to optimise the manufacturing process towards enhancing the process technology readiness level.

In addition to creating a set of reproducible experimental data, the study facilitated numerical models to predict the composite properties. These findings are then employed to optimise the manufacturing process towards enhancing the process technology readiness level.

Graphene, and more generally carbon in its many forms, is pushing the boundaries on what can be achieved in terms of electromagnetically-enhanced materials.

Nanomaterials, in the forms of coatings and structural elements, are under intensive investigation. It is critical to have robust technical data on the manufacturing, optimisation and multi-scale modelling of electromagnetic performance of hybrid composite structural components to provide advanced EMI shielding solutions for future use across a variety of industrial platforms.

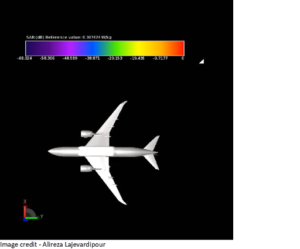

Finite-difference time-domain simulation setup for the new composite materials model (Image credit – Dr Alireza Lajevardipour)

The technological understanding of EMI shield composite structures also provides new capabilities/opportunities for several industries including electronic communication and control within defence and aerospace.

For further reading, the published article can be freely accessed via Carbon Trends – Liam Anderson, Premika Govindaraj, Andrew Ang, Azadeh Mirabedini, Nishar Hameed, “Modelling, Fabrication and Characterization of Graphene/Polymer Nanocomposites for Electromagnetic Interference Shielding Applications”

Featured picture: Nishar Hameed and Liam Anderson

Dr Nishar Hameed is Group Leader in Smart Materials and Composites and an Australian Research Council DECRA Fellow at Swinburne University.

@AuManufacturing’s editorial series – fibres and composites transforming industry – is brought to you with the support of ThermoFisher  Scientific and the Advanced Fibre Cluster Geelong.

Scientific and the Advanced Fibre Cluster Geelong.

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos