Fibres and composites transforming industry: There are Australians chasing the holy grail, but they can’t talk about it yet

This short installment of our Fibres and composites transforming industry series looks at the cutting-edge of pressure vessel construction, known as Type V. Work is underway in Australia on design and manufacture of these, but few details are being shared right now. By Brent Balinski.

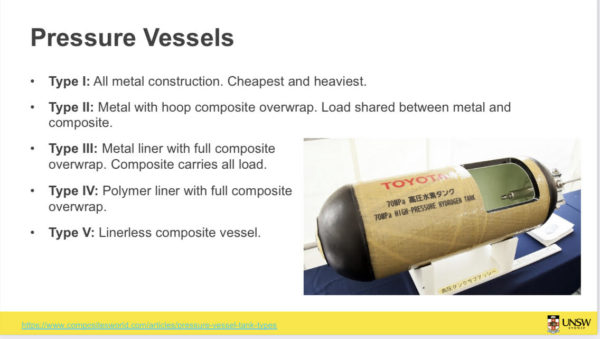

Those who study the evolution of pressure vessels break progress down into five generations so far.

The fifth and most advanced is Type V (see diagram.) A linerless vessel. Nothing but composites.

In the space industry — where there’s a very real and very large dollar value attached to every kilogram travelling — the appeal is easy to understand. If you can hold cryogenically compressed fuel in a tank and don’t need a metal liner for it, then that’s worth a lot of money.

According to one linerless tank developer, Infinite Composites Technologies of Tulsa, Oklahoma, their vessels offer a 90 per cent weight reduction versus steel or 40 per cent versus “other composite pressure vessels.”

Composites World describes Type V as the “holy grail” of pressure vessels.

Of course, designing and making one requires highly sophisticated engineering.

Some articles mention a dissolvable mandrel, around which fibres/resin are wrapped.

https://lngfutures.edu.au/wp-content/uploads/2019/10/Pearce-G.-Design-of-Linerless-Carbon-Fibre-Composite-Pressure-Vessel-for-Cryogenic-Fuel-Tank-Applications.pdf

Making a tank that keeps its integrity without a liner comes with a set of significant challenges, especially if it’s to be used for cryogenic fuel storage (under minus 150 degrees Celsius.)

The different rates fibre and resin expand and contract at — considering extremes of autoclave curing and storing liquefied gas — can cause cracking. Graphene nanoplatelets have been used to block these cracks from forming, as well as to help strengthen the bonds between layers.

According to one expert, mainstream usage will require further progress in materials, design and tooling.

There are Australian companies and researchers cooperating to develop Type V tanks. They appear tight-lipped about what they’re doing and how.

One space startup approached for comment said they would prefer not to speak, “as any comments may give the game away.”

UNSW is involved, though the work — as it is being done collaboration with private businesses — is not up for discussion. One of the businesses involved didn’t reply to a request for a chat.

UNSW Professor Gangadhara Prusty, Director, ARC Training Centre for Automated Manufacture of Advanced Composites, said it was difficult to talk about the subject without giving examples, which would mean commenting on work with collaborators.

“In any engineering, without giving an example it doesn’t make any sense…” he tells @AuManufacturing.

“So the question immediately becomes ‘have you done it? Is there anything possible? Where can it be applied?’”

Prusty doesn’t rule out talking about the cutting-edge problem in the future, but it would need the blessing of the centre’s network of partners. This is understandable. Companies working with outside researchers expect and deserve to have their confidentiality respected.

For now, we just know that R&D is being done here on a fascinating new generation of pressure vessel, highly sought after by the space industry.

We look forward to hearing more about it when the time is right.

Picture: www.infinitecomposites.com/infinite-composite-pressure-vessels

@AuManufacturing’s editorial series – fibres and composites transforming industry – is brought to you with the support of ThermoFisher  Scientific and the Advanced Fibre Cluster Geelong.

Scientific and the Advanced Fibre Cluster Geelong.

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos