Hypersonix and SoMAC CRC aim for high temperature materials

Hypersonic vehicle developer Hypersonix Launch Systems and the Sovereign Manufacturing Automation for Composites Cooperative Research Centre (SoMAC CRC) have joined forces to tackle one of the big issues facing hypersonic flight – high temperature material integration.

Hypersonic vehicles that travel at least five times faster than the speed of sound require materials that can withstand extremely high temperatures caused by aerodynamic heating.

In partnership with The University of Queensland (UQ), the partners plan to develop the next generation of high temperature ceramic matrix composites (CMCs) tailored to hypersonic flight applications.

The Head of Research at Hypersonix Michael Smart said: “Our DART AE vehicles have the most demanding thermal-structural requirements.

“There is no better vehicle to put the project’s innovative outputs to the test.

“Our Engineering team are excited to be collaborating with SoMAC CRC and UQ to deliver outcomes that could see Hypersonix competing internationally, and Australia at the forefront of international space technologies.”

In March Hypersonix won its first major contract when it was selected from a field of 63 respondents by the United States’ Defense Innovation Unit (DIU) to provide aircraft for hypersonic tests.

CMCs are a rare class of material in that they are extremely lightweight and have exceptional heat resistance – typically competing attributes.

UQ will assist with manufacturing process development, characterisation, and design, to help identify appropriate and cost-effective CMC materials.

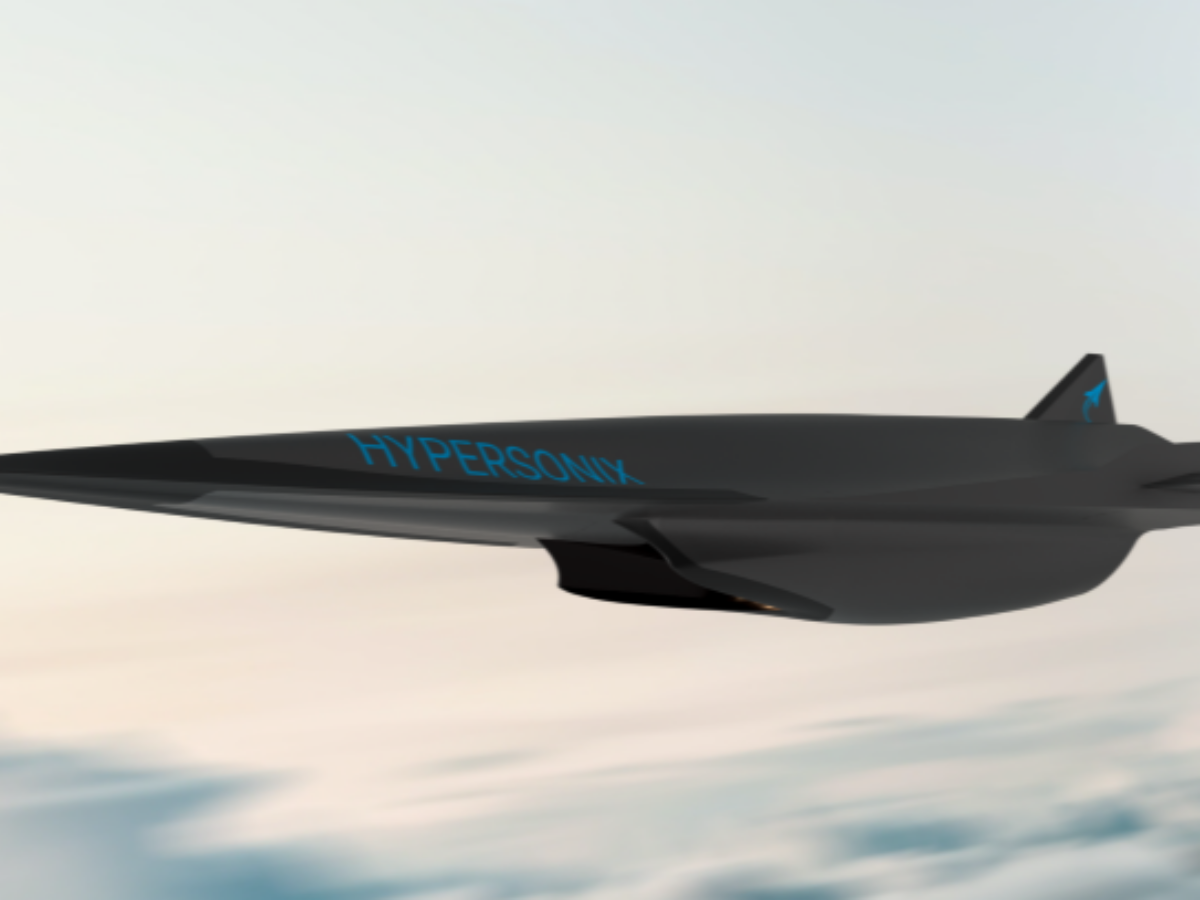

The resultant materials will then be integrated into a Hypersonix DART AE vehicle (pictured) for flight testing.

Co-Director for the Centre for Advanced Materials Processing and Manufacturing (AMPAM) at UQ Dr Michael Heitzmann said his group had pioneered CMC manufacture in Australia.

Dr Heitzmann said: “We’ve and are thrilled to be working with this collaborative team on a project that hopefully sees our materials being flown.”

SOMAC CRC CEO Steve Gower said the project would also be exploring novel net shape and short cycle time manufacturing methods for CMCs.

Net shape manufacturing is a process that creates an object that is complete without needing finish machining or any other finishing actions.

Further reading:

Hypersonix awarded first major contract

Picture: Hypersonix

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos