IMCRC, Allegra back implant technology development

A new industry-led project supported by the Innovative Manufacturing Cooperative Research Centre (IMCRC) will develop a proprietary coating process for orthopaedic implants.

Swinburne's ARC Training Centre for Surface Engineering and Advanced Materials, and RMIT will explore the coasting process which deposits a bioceramic material onto implants.

The project, which has been awarded $118,338 by IMCRC and Allegra Orthopaedics, will run for 12 months.

The manufacturing outcome for Allegra will be a robust coating process that manufactures a new product line of novel bioceramic coated orthopaedic implants.

The unique coating can outperform the current hydroxyapatite-coated implants, according to the research collaborators.

CEO of Allegra Jenny Swain said: “Together with our novel bioceramic material, this manufacturing process-material combination can expand its market within the biomedical industry.

“And it could be licensed to interested coating providers.”

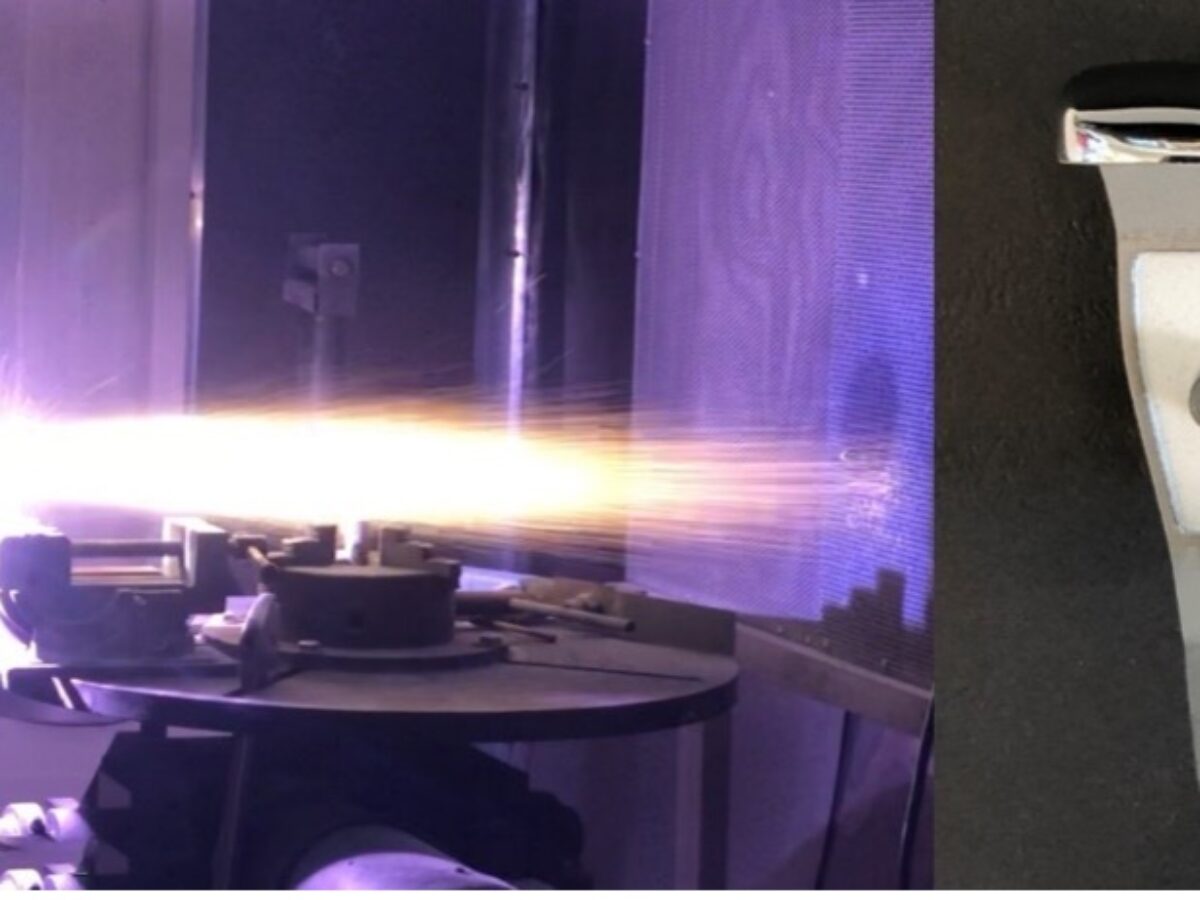

The process utilises a plasma spray process that creates nano-and-micro-scale features that better integrate with bone tissue as well as anti-microbial properties.

The research project will cover preparation of the material, plasma spray methods, coating optimisation and product evaluation.

IMCRC CEO David Chuter said the population was ageing and bone disease was on the rise.

“Allegra Orthopaedics will not only improve the coating quality and endurance of its medical implants but also significantly enhance the quality of life for many patients who otherwise might require frequent, complicated and expensive orthopaedic surgeries.”

Picture: IMCRC/Algera's novel coating process

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos