In the strain game

MicroBioGen is breeding world-renowned microorganisms, and believes these could be useful in everything from baking better bread to deep space travel. Brent Balinski visited the company's lab and heard about how baker’s yeast is ancient and ubiquitous, yet remains full of untapped potential.

Based in Northern Sydney’s Macquarie Park is a company dedicated to extending the usefulness of what’s been called the world’s oldest domesticated organism.

MicroBioGen launched their 1,250 square metre labs in October last year. There they focus on getting more out of yeast, a microorganism that CEO Geoff Bell says already underpins about $2 trillion of economic activity.

“It's absolutely entwined in your life,” he tells @AuManufacturing.

“It's the number one microorganism in the world… It takes these big industrial strands of things – whether it's corn or sugarcane or flour or plant matter – …and converts them into products.”

Bell’s company specialises in saccharomyces cerevisiae, better known as baker’s yeast, used for thousands of years to make products like bread and beer.

Alcohol in the form of bioethanol has provided early successes for MicroBioGen.

After launching their first product a few years ago, over half of North America’s biofuels are now produced using yeast designed by the company, says Bell.

“Within three years we went from nothing to number one,” he adds.

But MicroBioGen doesn’t export yeast, or at least not in the volumes needed to produce all that fuel. It bills itself a “yeast innovation as a service” provider, using evolution to provide “elite genetics” for its fungus.

For the ethanol example, it makes use of R&D programs including heat tolerance, acid resistance, osmotic stress resistance and ethanol tolerance to breed new products.

“Once we've got all these in the genetic toolbox, we can put them into the one strain” explains Bell.

Strains are then given to world-leading enzymes maker Novozymes, which scales these up and handles commercialisation, sales, and marketing.

It takes time

Patience has been necessary to get to this stage, agrees Bell, explaining this as standard for industrial biotech.

The company was founded in 2001 by microbiologist Dr Philip Bell (Geoff’s brother), Dr Paul Attfield, and two other principals, focussing on second-generation biofuels.

First-generation biofuels use crops as a feedstock. The second generation use non-food sources.

First-generation biofuels use crops as a feedstock. The second generation use non-food sources.

In 2006 the company had a proof-of-principle and attracted $6.8 million in investment. Besides federal grants totalling about $9 million, the only other money to come in was through a 23 per cent stake taken by Novozymes.

It took 15 years from establishment before an agreement was signed and another two before products were out in the market.

Today the company has revenues of $10 million, with this growing 65 per cent each year for the last four.

“It might sound like a dumb idea, but actually, the long-term nature of this business is one of our key competitive advantages,” explains Bell.

“And you can have the Chinese, you can have IFF, you can have these big corporations saying ‘We want to do what MicroBioGen has done.’ But it's going to take them 15 years, because you simply cannot speed up what we do.”

According to the company, it has spent half a million work days so far compiling its library of specialised strains.

It uses directed evolution for breeding better and better yeast. Over countless cycles, populations are bred, then desirable traits selected and amplified.

Bell says genetically modified yeasts industrialise badly and can be brittle, while his company’s approach gives a more robust result.

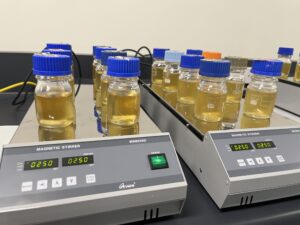

One important step in the breeding program is high-performance liquid chromatography.

Four HPLC machines were installed when the labs opened last year, with nine now running and two more on the way.

Each $75,000 machine can quantify things like how much glucose a sample consumed, how much ethanol it produced, and what byproducts resulted, measuring the efficiency of a strain.

“Unfortunately, they take 20 minutes to take a sample, or to do a full reading. And we literally have to look at thousands of strains a week,” Dr Phillip Bell tells @AuManufacturing.

“We have to do that every week for many years in a row to come up with one that is better. And so these are our rate-limiting step in a lot of ways. They run 24 hours a day, seven days a week.”

One long-project might involve strains optimised with space travel in mind.

Yeast is one of the contenders when deep space nutrition is considered.

“Yeast cells are a nutritious food source and have the potential to form a more significant part of a human’s diet, as they have a macronutrient profile similar to soy flour, with ~40.4% protein, ~34.6% carbohydrates, ~1.5% lipids, and ~13 kJ per gram of dry cell weight,” explains a paper in Nature Communications last year, adding that the amino acid profile of yeast proteins is also suitable, while growth is not significantly impacted by microgravity.

“Yeast cells are a nutritious food source and have the potential to form a more significant part of a human’s diet, as they have a macronutrient profile similar to soy flour, with ~40.4% protein, ~34.6% carbohydrates, ~1.5% lipids, and ~13 kJ per gram of dry cell weight,” explains a paper in Nature Communications last year, adding that the amino acid profile of yeast proteins is also suitable, while growth is not significantly impacted by microgravity.

Philip Bell says you might scrub carbon dioxide from the air and add it to hydrogen (made by electrolysis) to create a food source for yeast.

“Rather than… trying to grow bananas or something on Mars, you actually just scrub the carbon dioxide, have a source of electricity, and use that carbon dioxide to make ethanol,” he suggests.

“Then our yeast will make it into absolutely everything else you need to live on.”

A recent winner of NASA’s Deep Food Space Challenge, Air Company, had a similar-sounding proposal, making yeast-derived food from “astronaut breath.”

Only at the beginning

Among more immediate projects are delivering yeasts able to convert agricultural side streams into proteins for animal feed, create wines that can make their own preservatives, and increase profitability for bakers.

According to Geoff Bell, strains have been identified for commercialisation, and heads of agreements and term sheets agreed to with “one or two” international baking yeast companies.

“We obviously are a commercial company,” he adds of the priorities.

“Baking is 50 times larger than biofuels.”

He suggests such yeasts have been designed to grow on non-sugars and possess organic acid resistance, meaning they are cheaper to make, require fewer preservatives, and do the same job when used in smaller quantities.

Yeast cells sometimes get described as tiny factories, able to churn out a variety of products if they’re programmed properly and you give them a little sugar.

Though they don’t create yeast in huge volumes, MicroBioGen does breed and export it, while focussed on improving production within a series of industrial sectors.

So do they consider themselves a manufacturer?

“We're not a manufacturer. We are an R&D centre of excellence,” answers David Paton, head of business development.

“And then we then export.”

If you wanted to, you could spend all day on questions like “what makes a manufacturer?”

Philip Bell has perhaps not troubled himself with that question, though has definitely dwelled on the adjacent “who made whom?”

Asked what keeps him excited about yeast, he confesses that “You’ve got to be interested in something and I happen to be interested in evolution.

“Geoff wouldn't have mentioned it, but I'm also very much interested in evolution and the origin of life. And I have some controversial publications out there about the origin of life and stuff.”

He says the last thing with what seems like slight amusement.

A quick search shows the Director of Research was one of two people in 2001 who published a hypothesis on how a virus partnering with a prokaryotic (single-celled organism with no nucleus) host could have led to the nucleus in eukaryotes (cells containing a nucleus within a membrane.)

The next phase of MicroBioGen’s evolution will become clearer in time, but Geoff Bell says that all the projects mentioned above, plus quite a few else, will require a bigger team and more investment. An ASX listing in 2024 is a possibility.

Despite it being one of the best-studied eukaryotes, there is a tonne of unrealised potential left in saccharomyces cerevisiae.

“What we say is ‘whatever we've got today, we never get worse. We only get better.’ So if we get some you-beaut fantastic new strain, we put it all together, in three months time we’ll have a better one,” says Geoff Bell.

“We just continue to improve and add those features. Because there are so many features that are required in the industrial setting, there is lots of improvement to be done. And to give you an idea of the potential: yeast has 6,000 genes; the number of ways that you can [reassemble] them is more than the total number of atoms in the universe.

“And so we’re at the beginning of the journey, not at the end.”

Pictures: supplied

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos