Legrand is competitive with local manufacture – why not others?

By Peter Roberts

In all the orgy of offshoring that has hollowed out Australian manufacturing in the past few decades, few have stopped to ask why do those companies that remain local manufacturers remain here, when so many now source offshore?

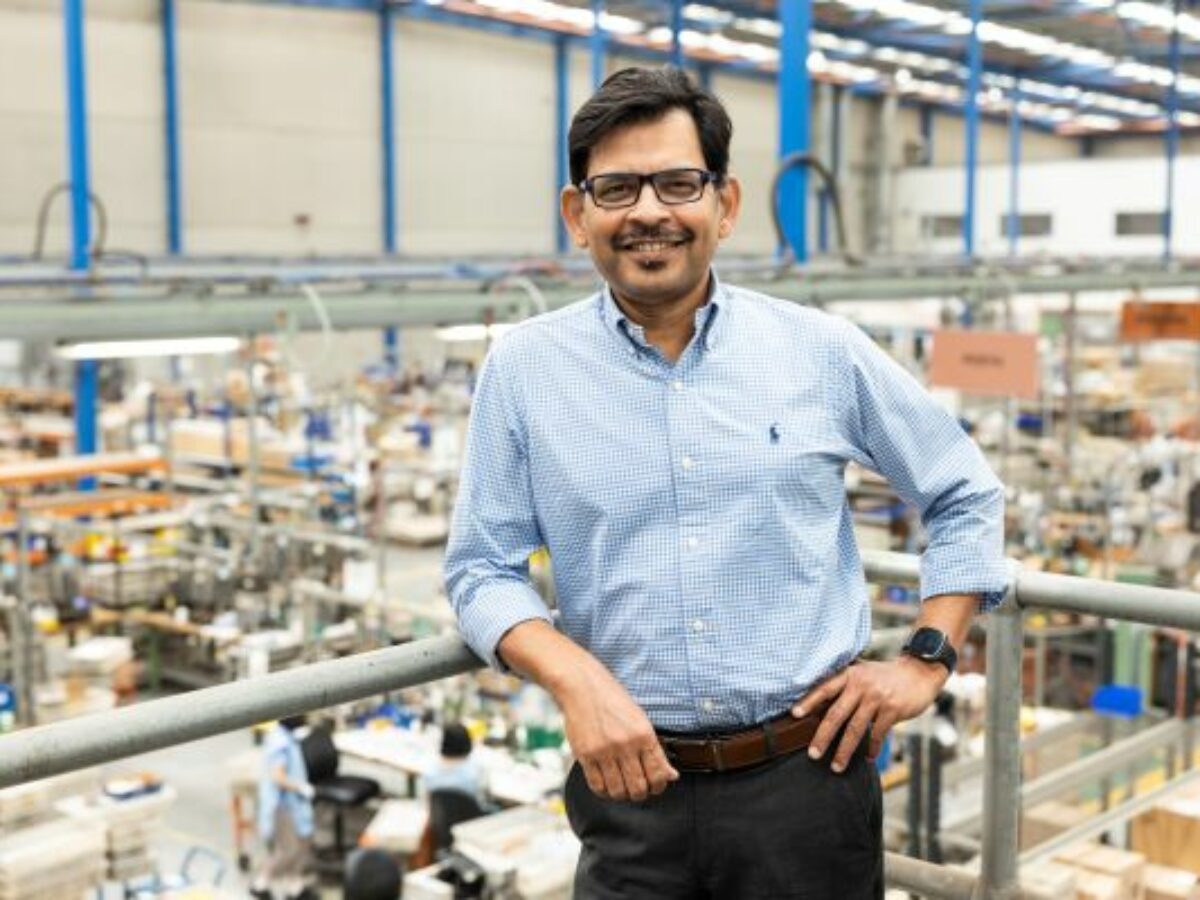

Palash Nandy, CEO of electrical equipment manufacturer Legrand Australia and New Zealand, has been involved in operational and strategic decision making in the French-based Legrand Group for decades and has a pretty good answer to that question.

Nandy told @AuManufacturing: “To be fair we have a mix of both local manufacturing as well as sourcing, so let’s say roughly 40 percent of our revenue is from product manufactured in Australia.

“We source some of the balance from Europe and some we source from China and India.

“Why manufacture in Australia? Legrand is an organisation that likes to be very local, we understand that the markets, the standards, the habits are very localised and therefore local manufacture gives us the ability to really be agile.”

Legrand manufactures 14,000 SKUs of switches and sockets and emergency lighting units which sell under well known brands Legrand, HPM, BTicino, Cablofil, Netatmo and CP Electronics.

Today they are manufactured at an impressive plant at Prestons in Sydney which employs 350 – I am old enough to remember when HPM, a much loved brand, manufactured from a jumble of buildings in a back lane in inner city Surry Hills. The company has a second plant in Auckland, New Zealand.

In the context of an EUR8.3 billion turnover company, ANZ is a rather small market, said Nandy.

“Still we hold quite a few strong market positions, emergency lighting is an example, wireless devices and power boards (that distribute a building’s electricity) are others.

“So with these products where we have a good market share, it allows us to still have local manufacturing and yet still be competitive.

“And yet what it gives us is flexibility – we are able to respond quickly to customers’ needs…to customisation.”

Legrand operates a R&D team which tailors products to individual order – an example being major hospitals which have special and individual needs. The team also keeps the company’s emergency lighting products at the cutting edge.

“This is something that we will continue to invest in.

“As we speak we are investing a lot in industry 4.0 – just two months back we invested in a cobot (collaborative robot) – we use it for manufacturing wiring devices.

“…Having had experience, we are convinced we should invest in more such things.”

The Prestons plant is widely capable, and is involved in everything from manual and automated assembly to metalwork, plastic injection moulding and the manufacture of surface mounted printed circuit boards.

The company’s warehouse is equipped with a novel paperless ‘voice picking’ technology, where staff are guided to pick components based on AI voice commands received through a headset.

The bottom line is that local manufacture is competitive for Legrand when you take into consideration flexibility, local customisation and innovation, and inventory and transport costs

Nandy said: “If you just think of the cost of producing a product you will reach a different conclusion perhaps.

“But if you look at the overall company picture, I strongly believe there is a strong competitive edge to manufacture locally.”

“While many of our friends if you put it like that have decided to go offshore for manufacturing, we are absolutely clear that for us there will always be a combination.”

Pictures: Legrand Australia/Prestons, NSW factory/Paslash Nandy

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos