Let’s bring AI2AM: AI-Augmented Additive Manufacturing

The future of AI-augmented additive manufacturing holds enormous promise, believes Dr Ali Zolfagharian. He explains the concept and why there's a new group dedicated to it.

Artificial intelligence (AI) has already made a significant impact across various sectors in automated manufacturing, but its by default integration into advanced manufacturing is about to reach new heights. With the launch of AI2AM (Artificial Intelligence-Augmented Additive Manufacturing), this transformative technology is set to revolutionise how we approach additive manufacturing (AM), marking a step change in the global landscape of smart manufacturing.

The recently-introduced AI2AM terminology in Australia aims to bring the emphasis on the necessity of augmenting AI as a key, not a fancy, player in accelerating the advances in manufacturing, particularly AM, creating a strategic international community of researchers and innovators who are working together towards this aim in this field.

The necessity of AI in Additive Manufacturing

AM, commonly referred to as 3D printing, has been around for decades. It has steadily evolved towards the creation of complex, geometrically precise objects layer by layer or even voxelised, as well as volumetric fabrication using materials such as metals, polymers, and ceramics. However, the promise often faces challenges such as material inefficiencies, defects during fabrication, and a lack of real-time monitoring and control. The emergence of AI2AM comes at a crucial time, as industries and researchers are beginning to realise the necessity of AI integration to push beyond the current limits of AM.

AI2AM’s potential lies in its ability to augment every stage of the AM process, improving outcomes at each step—from material design and process monitoring to post-processing and quality control. By leveraging AI, 3D printing systems can be transformed into smart, adaptive technologies capable of optimising performance and reducing errors, leading to significant gains in productivity, sustainability, and product quality and performance.

AI-driven preprocessing and design: A new era of materials innovation

One of the most exciting areas of AI2AM is its potential to revolutionise the preprocessing phase in AM. In traditional additive manufacturing, choosing the right materials and designing structures that meet the necessary specifications can be a tedious and error-prone process. However, by integrating AI, we can automate and optimise material selection, ensuring that the ideal materials are used for specific applications based on the desired properties, environmental factors, and manufacturing constraints.

The design phase of manufacturing will also experience profound enhancements through AI. In the current paradigm, designers and engineers must manually adjust models and predict material behaviors based on experience and simulations. With AI, machine learning and/or deep learning algorithms and large language models (LLM) can automatically generate and optimise designs based on predefined criteria, accelerating the design process while minimising material waste and reducing costs. This will lead to more efficient production, as well as the development of novel materials and structures that would otherwise be difficult, if not impossible, to create using traditional methods.

The design phase of manufacturing will also experience profound enhancements through AI. In the current paradigm, designers and engineers must manually adjust models and predict material behaviors based on experience and simulations. With AI, machine learning and/or deep learning algorithms and large language models (LLM) can automatically generate and optimise designs based on predefined criteria, accelerating the design process while minimising material waste and reducing costs. This will lead to more efficient production, as well as the development of novel materials and structures that would otherwise be difficult, if not impossible, to create using traditional methods.

As highlighted in the AI2AM framework, AI’s role in this phase ensures that the design process can account for unforeseen variables and material behaviors, leading to more reliable and customisable product designs.

Real-time monitoring and defect detection: Smarter manufacturing

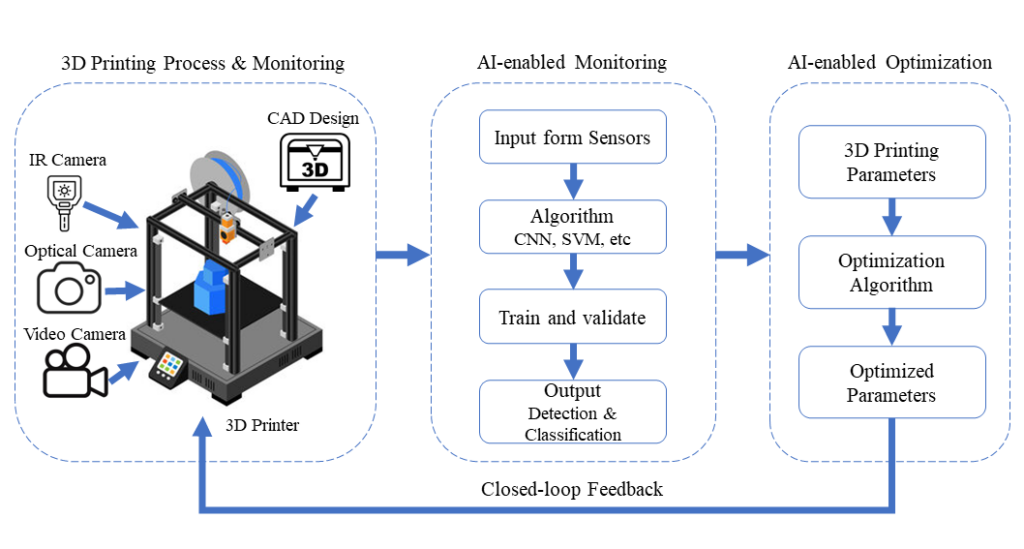

One of the core challenges in AM is the lack of real-time monitoring, making it difficult to detect defects or make corrections during the printing process. Traditional methods often result in time-consuming and costly post-production optimisations. However, the AI2AM introduces AI-driven systems that can monitor the manufacturing process in real time, identifying potential defects or anomalies as they occur. This capability is especially critical for industries like aerospace, medical devices, and automotive, where precision and accuracy are paramount.

For instance, AI can use advanced imaging techniques, such as computer vision and sensor data, to detect surface defects, thermal anomalies, or dimensional inaccuracies. This data can then be processed instantly to alert operators or, in fully autonomous systems, correct the issue in real time. By incorporating AI-driven feedback loops in the printing process, AI2AM aims to reduce errors and downtime, ensuring that manufacturers produce higher-quality products while minimising waste.

The research highlighted in a recently published article demonstrates how AI can use data from previous manufacturing processes to predict where defects are likely to occur and how best to address them before they result in significant issues. The integration of machine learning models for real-time monitoring offers an unparalleled opportunity to improve the accuracy and reliability of AM.

Optimisation and quality control in post-processing

While much focus is placed on the actual printing process, AI2AM also addresses the critical role of post-processing, particularly in 4D printing and the performance of additively manufactured parts. In 4D printing, where printed objects are designed to change shape or function in response to external stimuli, AI plays an indispensable role in controlling and optimising these transformations. AI can predict how materials will behave under various conditions and adjust the printing process accordingly to ensure that the final product performs as expected.

Moreover, AI’s application in quality control ensures that parts meet the required specifications and standards before they are used in real-world applications. By analysing data gathered during the manufacturing process, AI algorithms can identify patterns and anomalies, providing insights that can lead to more efficient and reliable quality assurance. This level of predictive maintenance and performance optimisation is essential for industries looking to adopt 4D printing and other advanced manufacturing techniques for critical applications.

Moreover, AI’s application in quality control ensures that parts meet the required specifications and standards before they are used in real-world applications. By analysing data gathered during the manufacturing process, AI algorithms can identify patterns and anomalies, providing insights that can lead to more efficient and reliable quality assurance. This level of predictive maintenance and performance optimisation is essential for industries looking to adopt 4D printing and other advanced manufacturing techniques for critical applications.

AI2AM: A global community with far-reaching impact

The AI2AM community, initiated in Australia, aims to gain traction on the national and global stage, drawing together experts in fields ranging from materials science and mechanical engineering to artificial intelligence and computer science. The establishment of this international community is pivotal for fostering cross-disciplinary collaboration and innovation, ensuring that the insights and advancements made in AI2AM are shared globally. The community’s goal is to not only push the boundaries of what is possible in AI-augmented AM but also to ensure that these innovations are accessible and beneficial to industries worldwide.

Integrating AI as an indispensable part of manufacturing

The potential applications of AI2AM are vast and transformative. In the coming years, we expect to see AI further integrated into every aspect of manufacturing, with additive manufacturing and 4D printing leading the charge. By augmenting traditional processes with AI, we will create smarter, more adaptable manufacturing systems capable of producing dynamic, high-performance materials tailored to specific applications.

AI-driven simulations will allow manufacturers to predict how products will perform under different conditions, enabling them to make real-time adjustments to ensure optimal performance. This will reduce material waste, lower production costs, and improve product longevity, aligning with the broader goals of sustainability in modern manufacturing.

As the AI2AM grows, its contributions will not only redefine advanced manufacturing but also set new benchmarks for collaboration, innovation, and real-world impact. By embracing AI and leveraging its transformative potential, AI2AM aims not just to enhance the capabilities of additive manufacturing, but to reshape the entire advanced manufacturing field, creating smarter, more efficient, and more sustainable manufacturing processes. The future of AI-augmented additive manufacturing holds enormous promise, and AI2AM is at the forefront of this revolution.

Join us in integrating AI as an indispensable part of manufacturing through AI2AM.

Pictures: supplied

Dr Ali Zolfagharian is the Australian Research Council's (ARC) DECRA Fellow and 4D materials leader at Deakin University.

Learn more and get involved at the links below

Artificial Intelligence-Augmented Additive Manufacturing: Insights on Closed-Loop 3D Printing

The AI-Augmented Additive Manufacturing community

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos