Li-S Energy’s success with solid state lithium sulphur battery

Battery technology startup Li-S Energy has announced the development its first 20 layer battery cells utilising its third generation semi-solid state lithium sulphur chemistry.

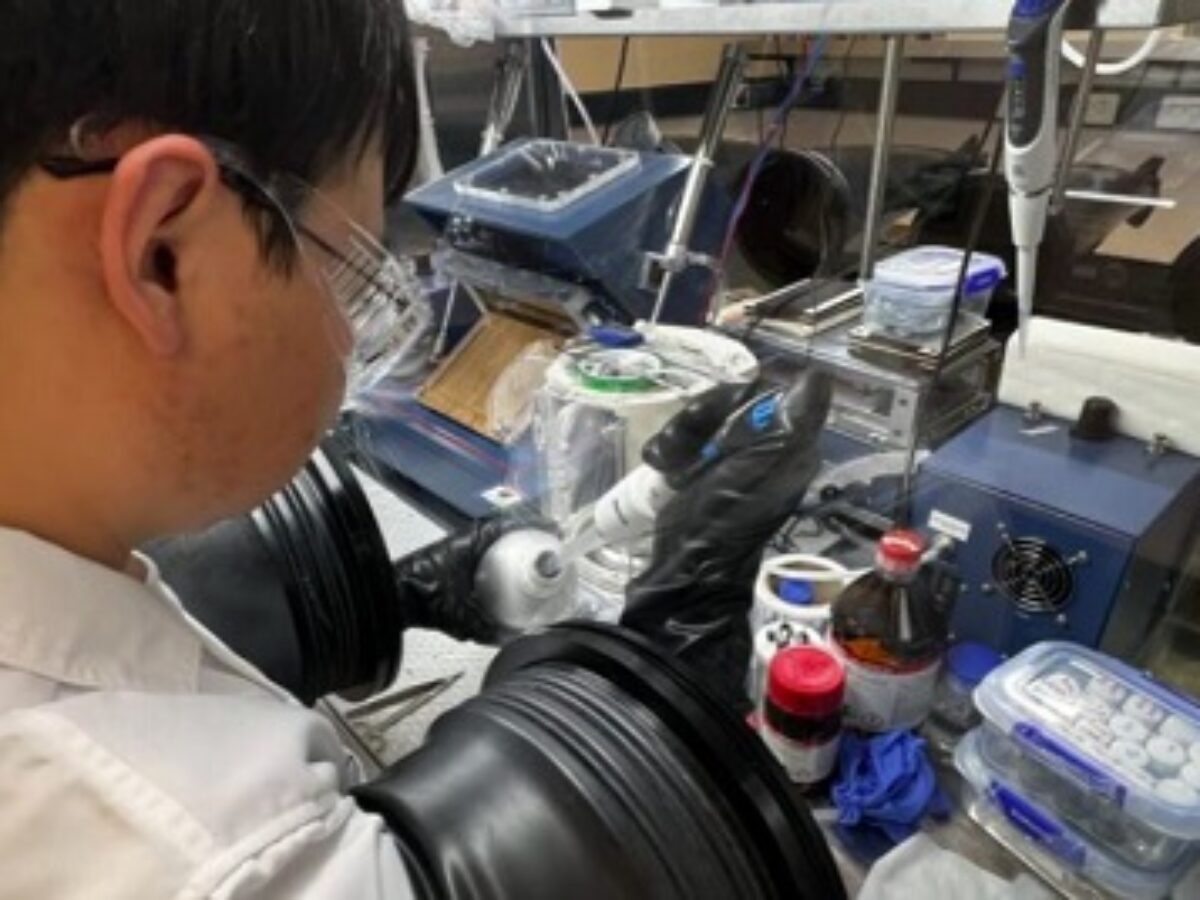

Developed in association with Geelong, Victoria's Deakin University, the cells were produced at the company's semi-automated Phase 2 manufacturing facility which is being further expanded with plans to produce test cells for potential customers later this year.

The batteries are produced with a low flammability electrolyte – one of the bugbears of traditional lithium ion and lithium sulphur batteries – and have a greater energy storage density – meaning batteries could be reduced in size and weight, or increased in energy capacity.

Battery life is also extended with the incorporation of boron nitride nanotubes (BNNTs) and a new nano-composite called Li‑nanomesh. In the past lithium sulphur batteries have had a shorter than expected life because of ‘dendrite' growth in the cells during charging and discharging.

This significant announcement was anticipated by the stock market with shares in Li-S Energy jumping 41 percent and its parent company PPK Group soaring 25 percent yesterday before trading was halted.

Li-S Energy CEO Lee Finniear said: “The development of these new battery cells is another validation of the stength of our scientific and technical teams, and our collaboration with Deakin University and other Australian and international institutions.

“…In the coming months we look forward to commencing the production of commercial samples for our partners.”

PPK Chairman Robin Levison said the development of a 20 layer battery was a major achievement by the company over the past 12 months.

Levison said: “The potential to significantly reduce the physical size of the battery packs through the 45 percent increase in volumetric energy will undoubtedly be of significant commercial interest to high value partners in sectors such as drones and aviation.

“These pivotal results are a testament to the LI-S team and further validate the patent protected Li-nanomesh technology and benefits of incorporating boron nitride nanotubes (BNNTs) into the cell construction.”

Picture: Li-S Energy/Geelong manufacturing facility

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos