Lithium looks to recycling as fertiliser additive

New materials developer Lithium Australia has completed short duration glasshouse testing of fertilisers with added micro-nutrients derived from recycled alkaline batteries.

The Perth company reported plant uptake of zinc and manganese was in line with expectations for oxide materials.

More than 6,000 tonnes of alkaline batteries are consumed nationally each year, with 97 per cent disposed of as landfill.

Lithium Australia is developing a closed loop battery metals business from mining to recyling and re-use.

The mixed metal dusts used in the trial came from the company's Envirostream Australia spent battery recycling facility in Victoria.

The company collects batteries from pick up points including Bunnings, Officeworks and Cleanaway, sorts and shreds them and then separates cathode and anode active compounds.

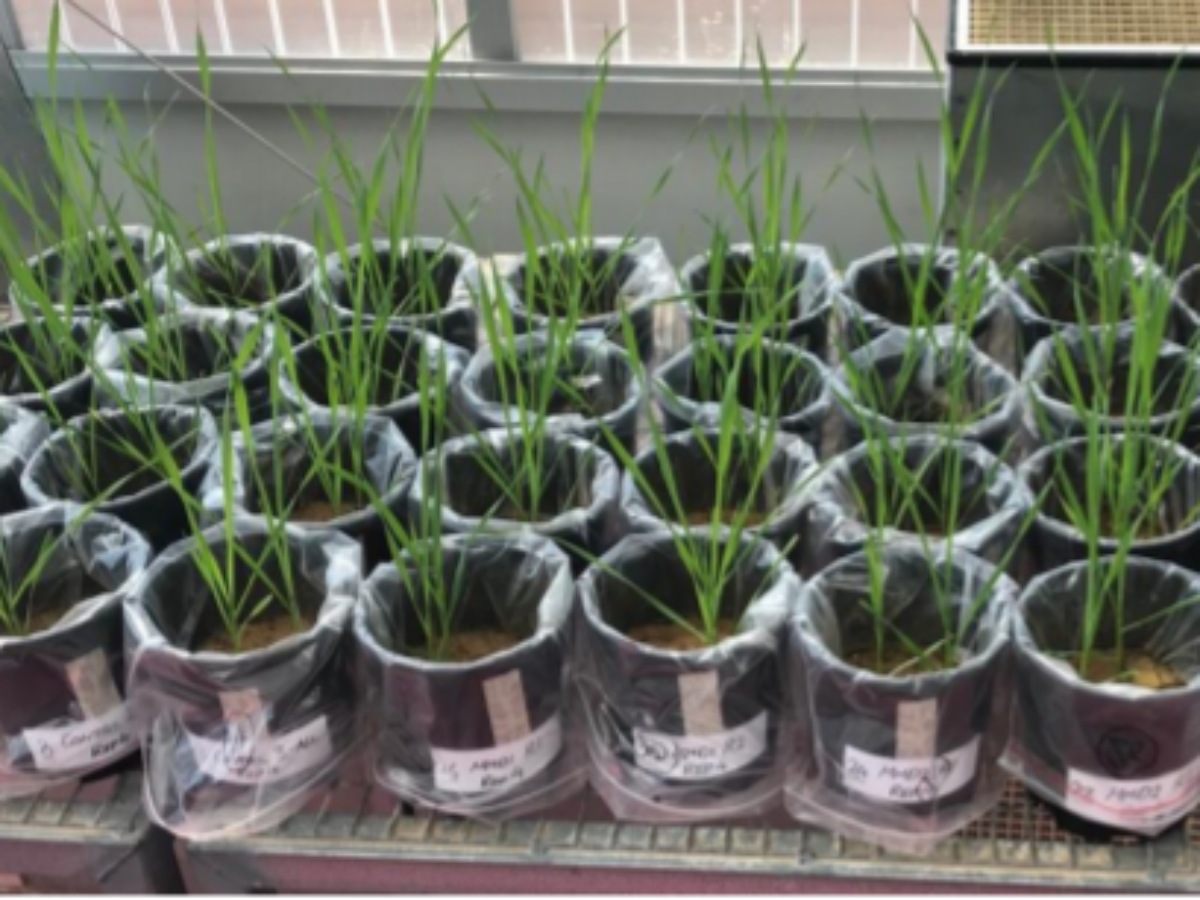

In the Lithium trials glasshouse pots (pictured) wereused to assess fertilisers against control samples, including traditional fertilisers.

Mertals uptake occurred across the samples, with uptake from recycled materials slower in comparison to fertiliser-grade sulphate products.

The company told investors: “That said, the results were encouraging enough for the company to commit to the next stage of assessment.”

Larger scale field trials are now being planned to assess alkaline mixed metal dust performance against conventional treatments.

Picture: Lithium Australia

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos