Magnetite to green iron project beckons for Lincoln Minerals

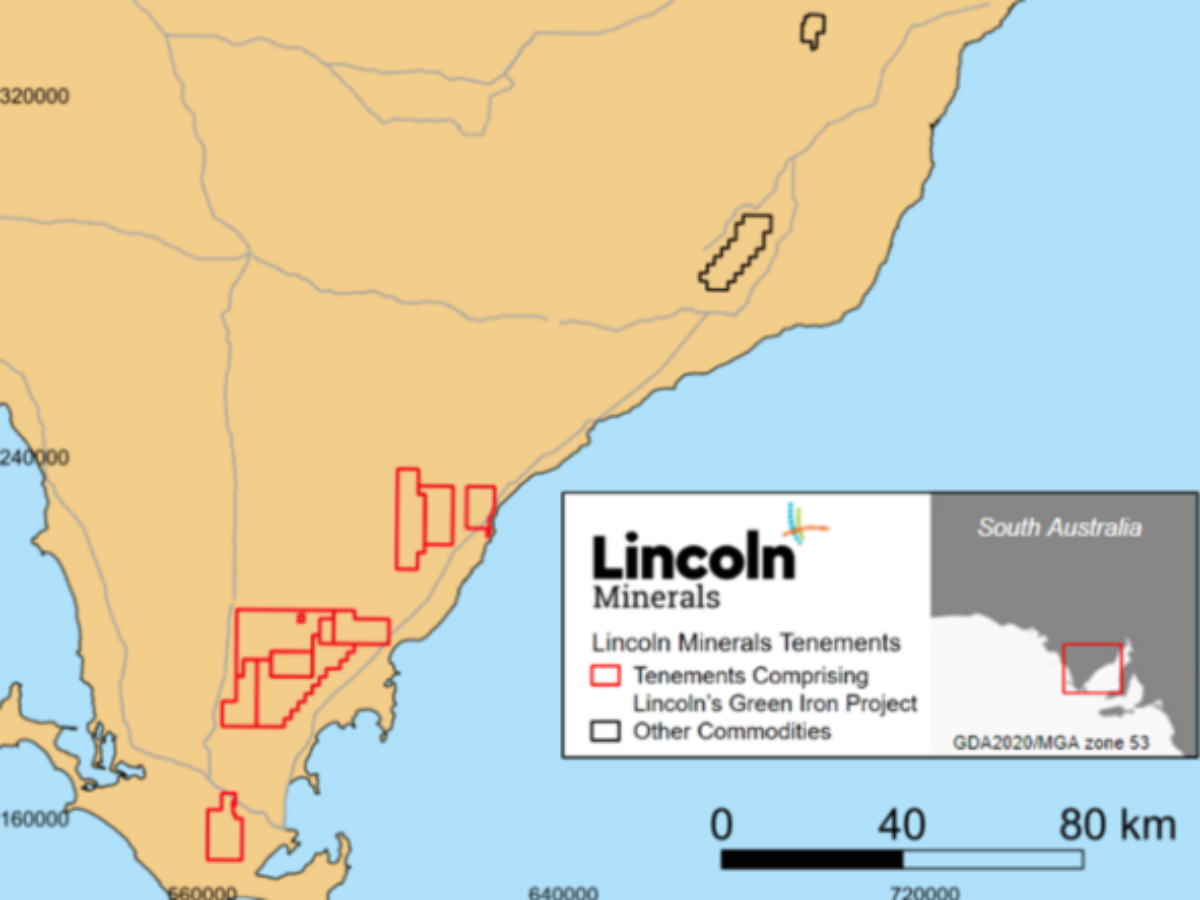

Lincoln Minerals will begin a partnering process for its large-scale Green Iron Project on the Eyre Peninsula in South Australia, which is underpinned by a recently announced 1.2 billion tonne (Bt) magnetite resource.

The company aims to identify a funding and project partner for advancing the Green Iron Project to operational status.

Magnetite is a form of iron ore more suited to direct reduction iron (DRI) processes, including utilising green hydrogen, than traditionally mined hematite iron ore.

GFG Alliance's Liberty steel group is already moving to utilise magnetite to produce green iron pellets and electric arc furnaces at Whyalla also on Eyre Peninsula to produce green steel.

Lincoln Director Julian Babarczy said: “We believe there is substantial potential value in Lincoln’s 100 percent owned Green Iron Project, which in our view is currently not reflected in Lincoln’s share price, due to a lack of awareness by the market of the scale and attractiveness of previous study outcomes.

“During the strong iron ore pricing environment of 2010-2012, the project attracted significant funding as well as strong engagement from major steel companies, however project advancement halted

due to the retracement of iron ore prices in subsequent years.”

The company's resource encapsulates a total magnetite Mineral Resource of 1.2 Bt at an average head grade of 25.7 percent Fe (iron), producing average concentrate grades of 66.4 percent Fe.

The Green Iron Project partnership process involves progressing the project to Definitive Feasibility Study (DFS) status and completing necessary approval documents.

Lincoln CEO Jonathon Trewartha said: “Magnetite, with its environmental advantages, has emerged as an appealing option for sustainable, low carbon steel production.

“Lincoln’s Green Iron Project…is expected to attract interest from potential steel producers, as has been the case with other peers in the region.”

Further reading:

Whyalla says goodbye to coal as steelmaking goes green(er)

Image: Lincoln Minerals

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos