Manufacturing news briefs — stories you might have missed

Latrobe council calls for transition support following paper mill uncertainty

Latrobe City Council has said it wants partner with the federal and state governments on “a collaborative transition for the region” required due to the “decline of large industry in past years”. The decline had been exacerbated by a warning from Opal, owners of the Maryvale Paper Mill, that worker stand-downs may become necessary following a supply issue with hardwood pulp for paper and paper packaging lines. Prior to that, coal-fired power station operator AGL announced in September that it will close Loy Yang A by 2035. “We need support, as Latrobe City will be most directly impacted through the loss of direct and indirect jobs across our major industry sectors,” said Mayor Kellie O’Callaghan. “The Mill has been a cornerstone of the region’s economic landscape for over 85 years, and like the proud history the region has with power generation, the impacts through closures or reduced operating capacity will be felt far and wide.”

Extended reality technologies show untapped promise for SME manufacturers

Many Australian SME manufacturers are yet to realise the benefits of low-cost extended reality (XR) technologies, believes Anthony Franzè, Industrial Designer and Project Coordinator at the Advanced Robotics for Manufacturing (ARM) Hub. Franze, a PhD student specialising in augmented fabrication, is lead author of a new research paper on the use of tech such as augmented reality (AR), mixed reality (MR), and virtual reality (VR), which he said some Australian manufacturers were taking advantage of “to produce better quality, highly customised, low-volume, and bespoke products.” However, uptake is currently low, “despite the potential benefits across many facets of manufacturing, such as product design, prototyping, training, maintenance, fabrication and assembly.”

Monash develops world-first sperm syringe for infertile couples

A syringe using a 3D filter to detect viable sperm can increase sperm quality selection by 65 per cent, according to Monash University, offer hope for couples previously unable to conceive. The world-first syringe could isolate quality sperm in less than 15 minutes, and represented “the biggest innovation in sperm selection technology in 30 years” said the university, where bioengineering researchers have developed a “simple plastic syringe technology, which can be readily mass produced”. It works by drawing 1.5 millilitres of semen into a chamber that then passes through a network of 560 parallel microchannels (tiny cylinders), with quality sperm swimming through microchannels into the selection chamber, where they can be extracted, leaving the poor-quality sperm behind. This process sees over 41 per cent of healthy sperm able to be retrieved from the sample. “Using the sperm syringe we can select sperm with over 65 per cent improvement in DNA integrity and morphology (make-up), and since DNA quality is directly linked with fertilisation success, we expect to improve assisted reproductive technology (ART) outcomes,” said. supervising researcher Dr Resa Nosrati.

UNSW solar tech innovator wins at PM's science awards

Two UNSW academics have been honoured with the Prime Minister’s Prize for Science and the Prize for New Innovators in the same year, according to the university. Trevor McDougall’s ground-breaking research has transformed the field of oceanography, while Associate Professor Brett Hallam is credited with making one of the most important improvements to photovoltaic technology in the last 10 years, it said in a statement on Tuesday. On Monday evening day the pair won at the nation's most prestigious awards for scientific research, innovation and teaching. UNSW Engineering's Hallam — an expert in hydrogen passivation for solar cells — took out the Prize for New Innovators, recognising an early achievement towards commercialisation of scientific research with substantial societal benefits. “It's a really big honour to receive this award, particularly for the topic I was working on with the (inventor of solar cell technologies), the late Professor Stuart Wenham,” said Hallam “My team developed a technology to improve the performance of industrial solar panels, make them more reliable, and cheaper. In particular, we found a way to stop a form of ironic degradation when solar panels are installed in the field.”

Gold assay tech developers win innovation award

Also at the PM's Prize, the CSIRO's Dr Nick Cutmore, as well as Dr James Tickner and Mr Dirk Treasure from spin-out company Chrysos Corporation, were recognised for the successful commercialisation of PhotonAssay technology. The recipients of the Prime Minister's 2022 Prize for Innovation are behind a technology developed at CSIRO, delivering faster, safer, more accurate and environmentally friendly analysis of gold for the minerals industry. Chrysos was formed in 2016 to commercialise PhotonAssay, and has significantly grown installations since. Cutmore said in a statement that he was extremely honoured, and praised CSIRO for providing an environment where such initiatives were possible. “Being fully automated, PhotonAssay can deliver results to customers in a little as two minutes, unlike the days that could be required for traditional methods,” he added.

Zip Water achieves top five per cent score in sustainability ratings

Zip Water announced this week that it was recently awarded a gold medal sustainability rating by ratings organisation EcoVadis. According to Zip, it was subjected to a rigorous review process that covered four areas of the business, covering environment, ethics, labour and human rights, and sustainable procurement. Zip was found to be “in the 93rd percentile of companies assessed by EcoVadis” which claims “a global network of more than 100,000+ rated companies.” Zip, which is celebrating its 75th anniversary this year, said it was pleased with recognition for implementing sustainable practices. “To be recognised by EcoVadis as being in the Top 5 per cent of companies is tremendous,” said Managing Director of Australia and New Zealand Mike Abbott.

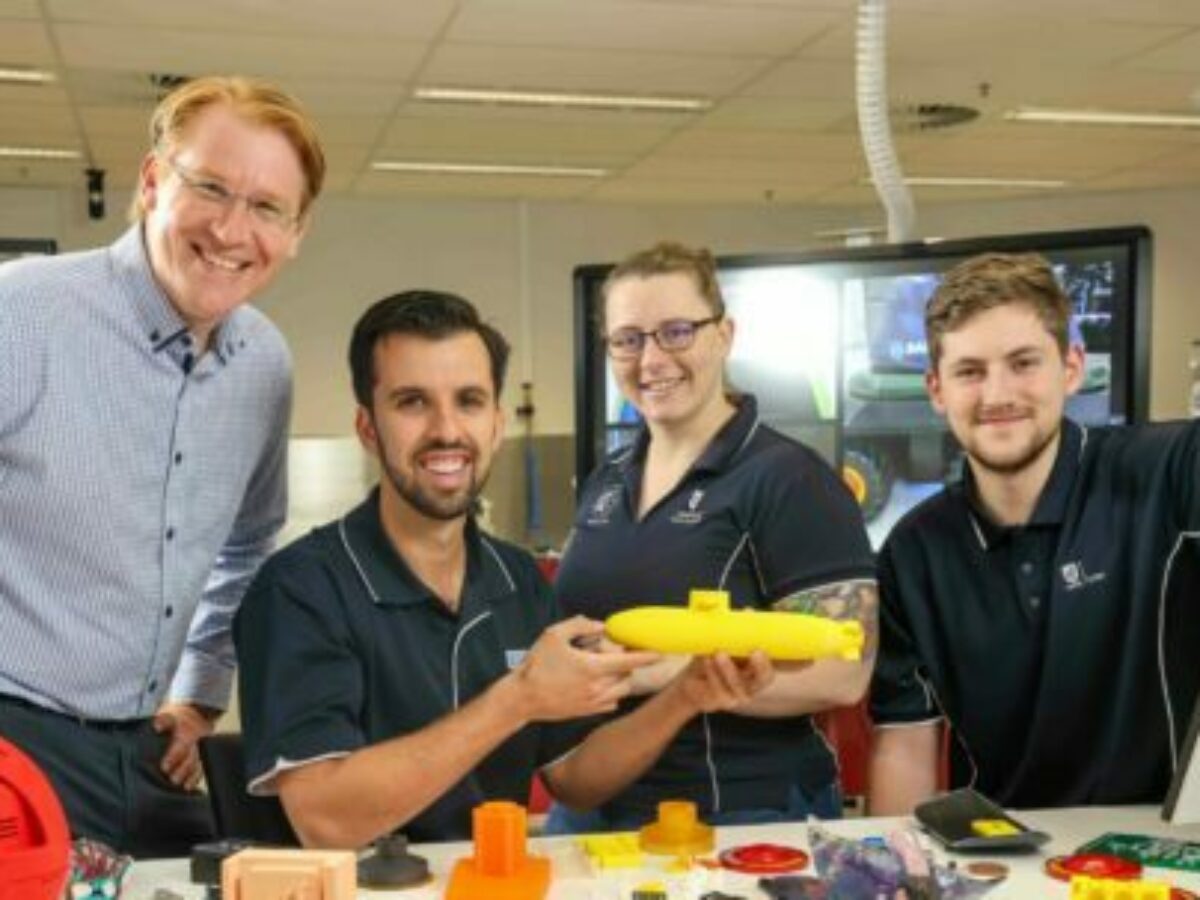

Exoskeletons, heat exchangers part of ASC’s university partnership

ASC has partnered with the University of South Australia in a program supporting engineering honours students. According to a statement from ASC, it is providing university students with experience working on projects for potential use in the Collins Class submarine program, with two of these including a study of specialised exoskeletons and the development of advanced heat exchanger technology. Exoskeletons are able to assist employees’ movements and improve safety, while the novel heat exchanger technology — called ‘tube dimpling’ — is also being tested and verified. The latter seeks to create a more efficient heat exchange to keep the submarine cool. ASC is providing in-kind support, including project supervisors and subject matter experts,

together with funding as required. “Honours students gain access to our experienced engineers, who work on the Collins Class

submarine program every day and are providing advice and guidance to help them refine their projects and skills,” said ASC Managing Director and Chief Executive Officer, Stuart Whiley.

Picture: supplied

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos