Manufacturing news briefs — stories you might have missed

NSW releases new guidelines for working with cobots

The NSW government’s Centre for Work Health and Safety has released what it says is a world-first set of guidelines for working safely with collaborative robots (cobots). Guidelines for Safe Collaborative Robot Design and Implementation were developed in partnership with Centre for Advanced Manufacturing, University of Technology Sydney, Robotics Institute, University of Technology Sydney, the Centre for Inclusive Design and Kairos Now. “Despite increasing cobot usage and the risks involved, there is a gap in the current workplace health and safety framework around how workplaces can safely engage with robots,” said Head of SafeWork NSW, Natasha Mann. The new guidelines can be downloaded here.

AusBiotech welcomes new NSW Biosciences Fund

Life sciences industry body AusBiotech has welcomed the recent announcement of a $40 million Biosciences Fund (BioSF) for NSW startups, researchers, and entrepreneurs to help them realise their full potential and assist them to bring their innovations to market. AusBiotech CEO Lorraine Chiroiu said funds like this are particularly important in an industry where access to capital can dictate whether or not a product makes it to market. “The biosciences sector in Australia has some of the best researchers and entrepreneurs in the world, developing lifesaving treatments and therapies,” said Chiroiu this week. “Initiatives such as the Biosciences Fund are critical to the future of this industry and help to enable the promise and potential benefits of biotechnology for Australia to be realised. The entire ecosystem needs to work in synergy to ensure our stability and competitiveness in a global environment.”

WA government to introduce climate change legislation

The Western Australian government will introduce climate change legislation this year, it announced on Tuesday, to establish a framework to meet the state goal of net zero by 2050, and formalise an aim to reduce government emissions by 80 per cent below 2020 levels by 2030. The legislation will create statutory requirements for the state government to set interim emission reduction targets and develop strategies to adapt to the impacts of climate change. Climate action minister Reece Whitby said legislation “will help accelerate our transition to net zero emissions in a responsible and achievable way,” as well as “help unlock critical investment in clean energy infrastructure and technologies, ultimately reducing costs for businesses.”

Bygen gets planning approval

Chemical engineering startup Bygen announced on Wednesday that a proposed activated carbon production facility in Swan Reach has been granted planning approval. “This facility will produce approximately 1500 tonnes of activated carbon per year from local nut shells using our low-temperature activation technology,” The company said in a statement on Linkedin. “With civil works beginning on the site and the first phase of equipment construction underway, this is a very exciting time for the team!” You can read a 2020 @AuManufacturing interview with the co-founder and CEO of the University of Adelaide spinout, Dr Lewis Dunnigan, at this link.

Codan achieves strong revenue and profit growth

Communications and metal detection manufacturer Codan has achieved revenue and profit for H1 FY23 at the high end of original estimates. The board had estimated revenue for the half of between $198 million and $215 million, and a net profit after tax between $25 and $30 million. The unaudited revenue achieved was $212 million with net profit that ‘may approach $31 million', according to an investor update. Communications revenues slightly exceeded expectations on an improved profit margin, while Minelab revenues were slightly below previous guidance. Net debt stands at $61 million, lower than the previously expected $70 million.

Recce Pharmaceuticals receives $6.2 million R&D tax benefit

Anti-infective developer Recce Pharmaceuticals has received a total Research and Development (R&D) cash receipt from the federal government of $6,219,241. This comprises $4,311,202 from the Australian Tax Office for the year ending 30 June 2022, and an advance payment of $1,908,039 from Radium Capital as a proportion of the company’s FY23 R&D applicable expenditure. The $4.3 million reflects the company’s expanded pre-clinical and clinical R&D activities undertaken locally and overseas during FY22, with the funds provided to the company in cash. The federal government’s 43.5 percent Research & Development Tax Incentive rebate is received for Australian-based R&D, however Recce was able to capture a payment for R&D applicable activities overseas.

Wine showcase event returns to London after Covid hiatus

The Australia Trade Tasting event returned to London on January 24, showcasing over 700 wines from 200 wine producers in more than 50 Australian regions to hundreds of trade and media personnel in the United Kingdom. The annual event has run for more than 30 years, with a hiatus in 2021 due to Covid-19. Paul Turale, Wine Australia's General Manager, Marketing, said “It’s clear there’s a real appetite from the on-trade and buyers to see more producers in market, pouring their wines and telling their stories about what makes Australian wine unique.”

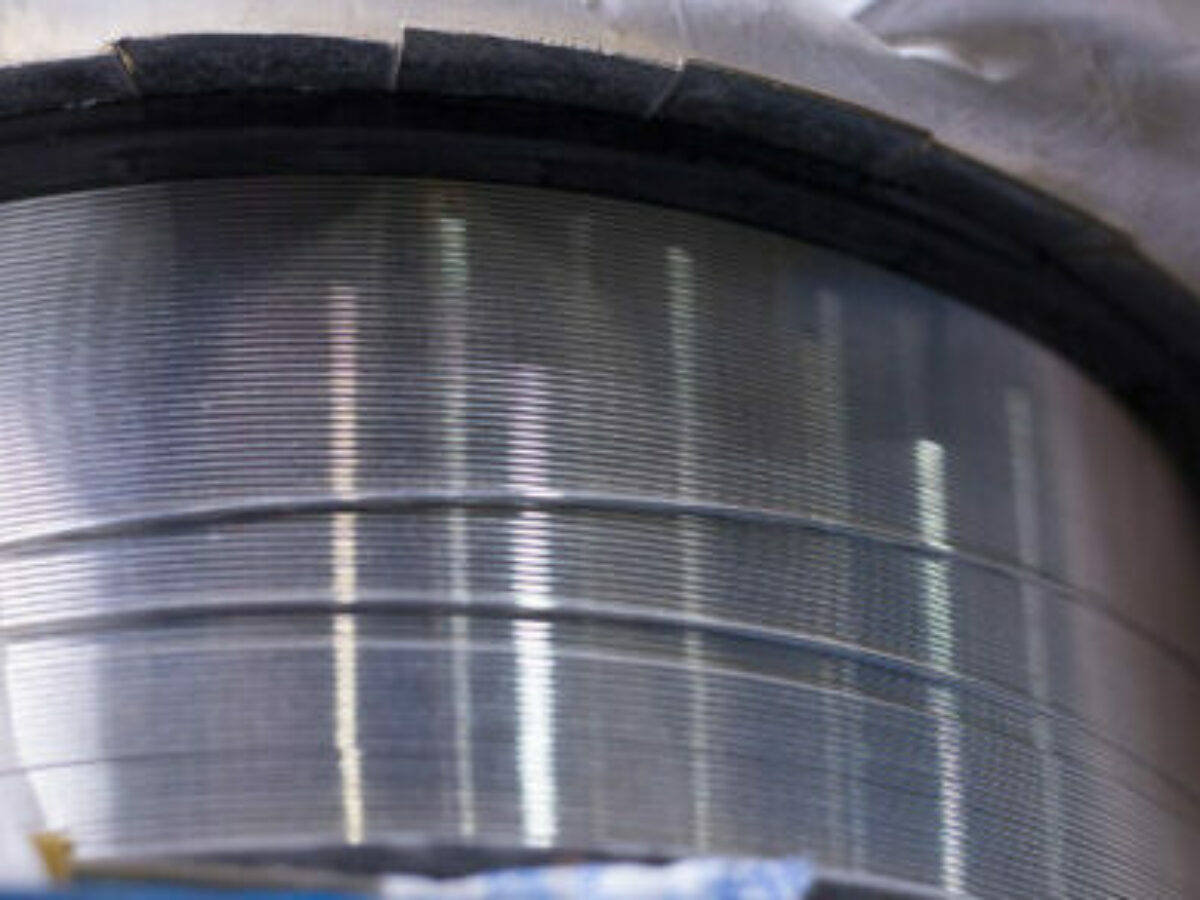

Deakin-AML3D project progresses new welding wire

An R&D project between Deakin University and ASX-listed metal additive manufacturing company AML3D has concluded, with progress towards commercialisation of a novel, high-strength aluminium wire feedstock for welding and 3D printing applications. The project was supported by an Innovative Manufacturing CRC grant. AML3D will undertake further work, including testing to industry standards, as it works towards a commercialisation pathway. The new wire (pictured) was developed in collaboration with Deakin's Institute for Frontier Materials (IFM), and is “set to transform the way complex metal objects are manufactured”, according to a statement from the IMCRC on Wednesday, and requires minimal or no heat treatment post-manufacture. “…[U]he aluminium alloys we currently use require up to 24 hours of heat treatment to reach optimum strength, which can be costly and creates some logistical challenges,” said Andy Sales, ALM3D’s Executive Director and Chief Technical Officer, adding “we’ve developed a cost-effective, high-strength aluminium alloy wire that requires just 30 minutes of heat treatment once printed.”

Cooperative Research Australia to hold CRC information session

Cooperative Research Australia will be delivering an information session on CRCs in collaboration with the Department of Industry, Science and Resources on 2:30-3:30PM, AEST, Wednesday February 8. According to CRA, the session will cover how to apply for a Cooperative Research Centre, what makes a competitive application, first-hand accounts from recent successful bids, and an opportunity to ask questions of the panel. The panel includes Chris Gonzalez, Department of Industry, Science and Resources; Wendy Craik, Chair, One Basin CRC; Ganga Prusty, Director of Research and Bid Lead, The Sovereign Manufacturing Automation for Composites (SOMAC) CRC; and Jane O'Dwyer, CEO, Cooperative Research Australia. More information and a registration frm can be found here.

Picture: supplied

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos