Manufacturing news briefs – stories you might have missed

ClearVue secures second solar window order from US customer

Building-integrated photovoltaics company ClearVue Technologies has secured a repeat order from System USA for a solar greenhouse demonstrator showroom. The $175,000 project will create a demonstrator greenhouse exhibiting ClearVue technology which generates electricity from its solar glazing. The project will be eligible for incentives under the US Inflation Reduction Act. The Global CEO of ClearVue Technologies Martin Deil said: “The global market for solar greenhouses is a critical part of our growth strategy. This repeat order validates our technology and strengthens our relationship with a key player in the US greenhouse industry.”

Microscopy technique shows way to new materials

A new microscopy method has allowed researchers to detect tiny changes in the atomic-level architecture of crystalline materials such as advanced steels for ship hulls and custom silicon for electronics. In a paper published in Nature Materials, researchers from the University of Sydney’s School of Aerospace, Mechanical and Mechatronic Engineering introduced a new way to decode the atomic relationships within materials. The breakthrough could assist in the development of stronger and lighter alloys for the aerospace industry, new generation semiconductors for electronics, and improved magnets for electric motors. “Our research presents a significant breakthrough in materials science,” said Professor Simon Ringer, a materials engineer in the School of Aerospace, Mechanical and Mechatronic Engineering (AMME).

New Queensland battery supply chain database

Queensland Manufacturing Minister Glenn Butcher has launched Australia’s first Battery Supply Chain Database (the Database). The database is a tool that will help battery technology companies identify business and supply chain opportunities to support domestic production. Manufacturers outside of the battery supply chain can also use the database to identify new customers and markets, and to connect with the battery supply chain and potential investors. Butcher said: “This is a great step forward to support an emerging battery industry…by getting in early, we can ensure Queensland manufacturers have the pioneer’s advantage, staking a claim in the marketplace and becoming established early.”

GSWA enters new MoU

Green Steel of WA has announced that it has entered a memorandum of understanding with Wajarri Enterprises, part of the Wajarri Yamaji Group. In a message on Linkedin on Friday, the company — which hopes to establish electric arc furnace steel recycling at Collie in 2026 — is it was looking forward to “working with Ehsan Haque and his team on mutually beneficial decarbonisation, recycling and mineral processing opportunities in the Midwest.” Wajarri Enterprises is the commercial arm of the Wajarri Native Title Group which covers over 85000 sqm of the Midwest and Gascoyne Region of WA.

SEMMA calls for debate on nuclear power

The South East Melbourne Manufacturers Alliance (SEMMA) has requested what it called a mature debate on the future of energy supply for manufacturers, citing recent member survey results. SEMMA said in a statement this week that 61 per cent of respondents agreed nuclear power could be a cost-effective and reliable energy source and 71 per cent said they were in favour of including nuclear power into their manufacturing energy mix. The number of respondents was not given. The nuclear option had merit when talking about “a long-term zero emission consistent energy supply,” said said Peter Angelico, SEMMA President. “Globally, there are 32 countries using nuclear power (a total of 440 reactors) and many have successfully combined these energy inputs, solved waste concerns and ensured an efficient, consistent, cost-effective, safe and sustainable energy supply for everyone.”

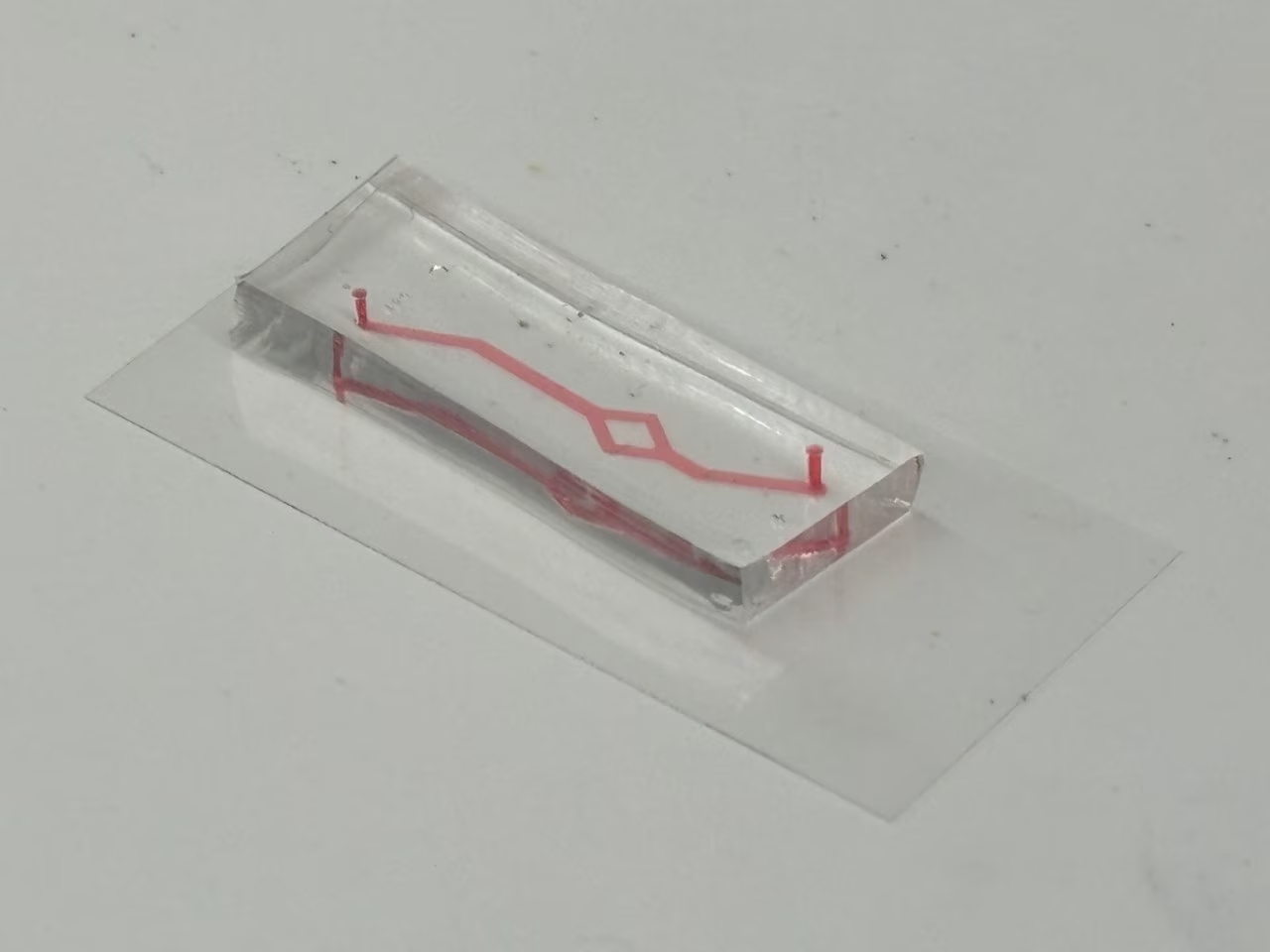

Researchers develop “blood vessel-on-a-chip”

This week the University of Sydney announced that its researchers had developed a “blood vessel-on-a-chip” for heart disease (pictured) “with the potential to change the future of drug testing and development” as well as reduce reliance on animal testing. According to the university, the team created a transparent microchip which mimics blood vessel damage due to high blood flow and inflammation, the first stage that leads to development of heart disease. “This is an incredible development because we took advantage of these microchips being made from a transparent material, and we mimicked the conditions of the coronary artery, that supplies blood to the heart muscle, and imaged them with a microscope to map the areas of cell damage which were similar to the locations of blockages in patients with heart disease,” said said Associate Professor Anna Waterhouse from the Charles Perkins Centre and the Sydney Nano Institute. The development of the technology has been published in two papers, Advanced Functional Materials and Advanced Materials Technologies.(accessible via the links.)

$50 million in funding to support SME clean energy financing

SMEs will be able to obtain cheaper finance for solar, batteries and more energy efficient vehicles and equipment, according to the federal government, with $50 million announced on Friday towards discounted loans. The funding through the Clean Energy Finance Corporation (CEFC) will go towards discounted finance “worth $250 million by non-bank lender Metro for electric vehicles, rooftop solar and batteries” with “farmers and other small businesses will also be able to access discounted finance for more energy efficient farm and building machinery such as tractors, harvesters, earthmovers and cranes. Eligible customers financing a $60,000 electric vehicle, for example, could save about $1,700 in interest over 5 years.”

Hendon Semiconductors awarded grant to support implantable device projects

Hendon Semiconductors, a division of Legend Corporation, announced this week that it has been offered a grant of up to $605,561 from South Australia’s Economic Recovery Fund Round 1. The grant will support what it described as a critical project upgrading facilities and equipment for developing and making medical products. The project has a total value of $1.23 million and will add clean room and sterilisation facilities as well as wafer to COB processing of semiconductors, and is “specifically targeted towards the support of higher reliability requirements necessary for implantable devices.” Winners of the SA Economic Recovery Fund grants were announced in early June.

Picture: An example of the transparent blood vessel on a chip (credit University of Sydney)

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos