New nanoscale 3D printing tech developed

Researchers have developed the first nanoscale 3D printing technique for synthetic bone substitutes.

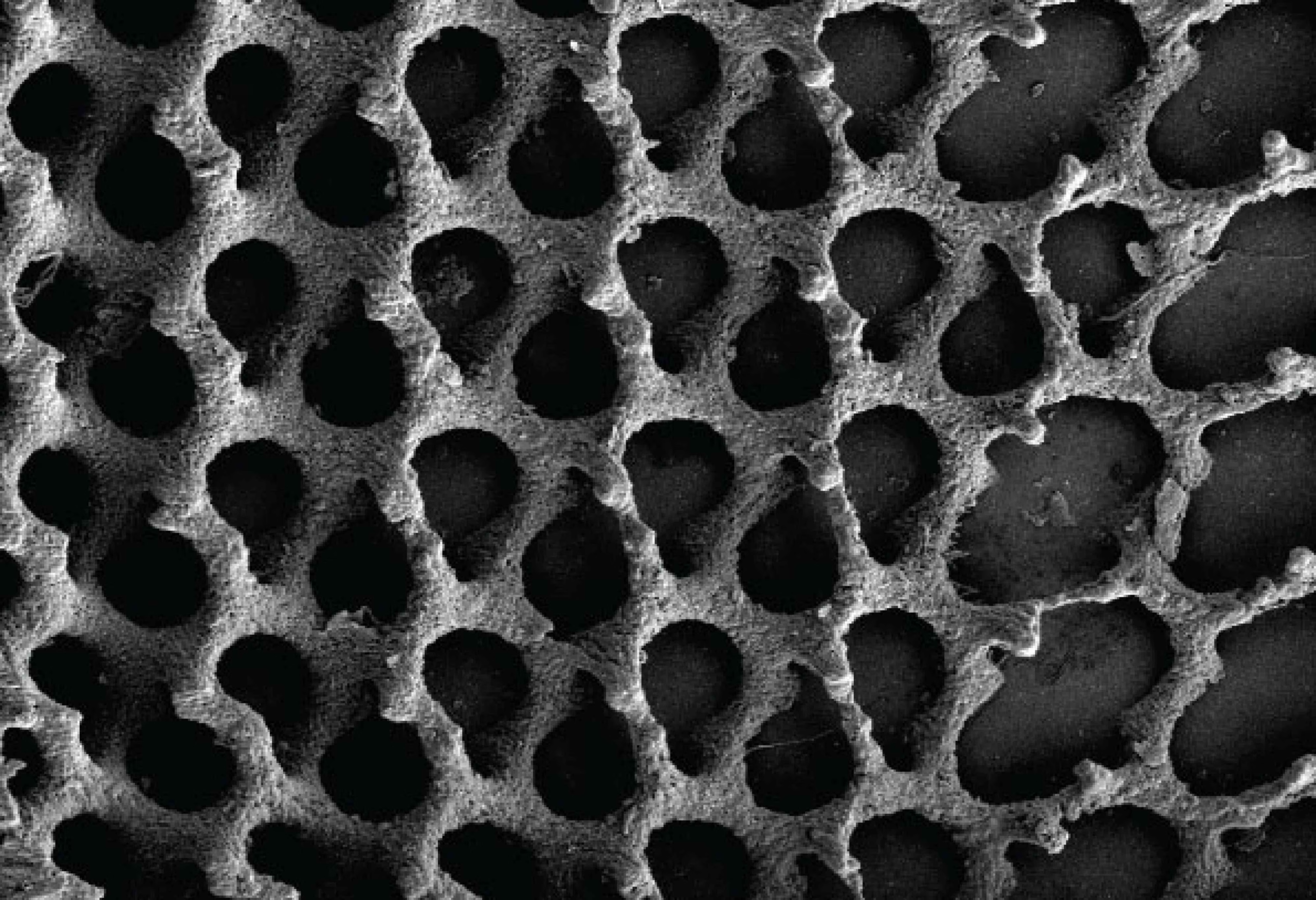

The development, made by researchers at the University of Sydney, make it possible to mimic bone anatomy and even control the grain size and how porous it can be during printing.

“Our bioceramic scaffolds aim to mimic the structure and properties of real bone, said Professor Hala Zreiqat, the Payne-Scott Professor of Biomedical Engineering at the University of Sydney, who co-led the development.

Just looking like bone is not enough – it needed to have similar strength and integrity. We were able to do it at the macro and micro level but achieving it at the nano level was the final piece of the puzzle – Professor Hala Zreiqat.

“The technology brings us a step closer to transforming bone graft surgeries in the future,”

The team were able to print at 300 nanometres resolution, which they say is one thousand times stronger than existing techniques.

The process uses biocompatible materials, such as calcium phosphate as printing materials. The machine used to print these bones is located at the Research and Prototype Foundry, one of the core research facilities at the University of Sydney.

Zreiqat said as this nanoscale 3D printing process allows for the mineral composition of natural bone to almost be replicated, it means human cells can recognise and interact with them more effectively. This manufacturing breakthrough puts the medical field a step closer to creating synthetic bone with the same strength and biological properties of natural bone.

“This reduces the risk of long-term complications and future surgeries and offers a more natural restoration of bone defects,” she said.

She noted that while the technology is still evolving, this breakthrough represents a significant step in reconstructive surgery.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos