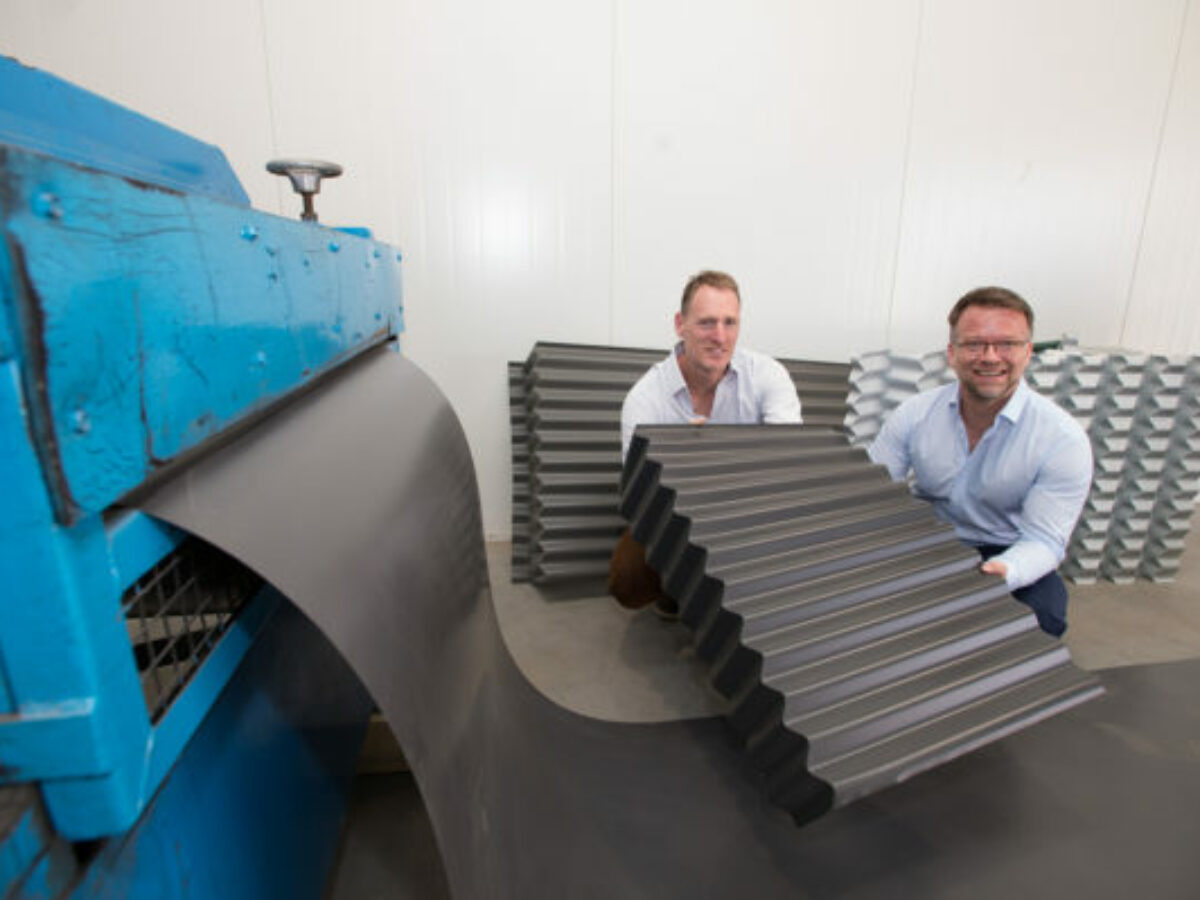

On a roll: FormFlow develop two new processes

FormFlow, Deakin University and the Innovative Manufacturing CRC have shared results of a collaborative research partnership, which they say has yielded commercially useful technologies for the metal forming sector.

The team originally announced a 12-month project backed by IMCRC’s activate program in January last year, targeting development of a “an Industry 4.0 enabled manufacturing cell” for FormFlow’s metal bending process.

Their project expanded following initial research, and grew to incorporate:

- A 2D laser system allowing continuous quality control, monitoring the cross-sectional shape of sheets before and after bending; and

- an Industry 4.0 manufacturing cell capable of producing a corrugated corner bend from a flat sheet of steel.

Dr Matthias Weiss, a Senior Research Fellow at Deakin’s Institute for Frontier Materials and a co-founder of FormFlow, commented on the value of flexibility in the project.

“Our research still focused on creating a high-volume manufacturing cell, but instead of implementing equipment to monitor and control the bend, we designed a new technology and forming process called the in-phase continuous corner (IPCC),” said Weiss.

“IPCC means we no longer need to compensate for differences in steel corrugations or work with fixed lengths. We can instead take a flat steel sheet and form an easy-to-install bend in continuous lengths.”

“Roll forming manufacturers are looking to FormFlow’s 2D laser system because it enables continuous, real-time quality control. The laser automatically measures the key parameters of the steel and provides the necessary data, something that is currently a manual, time consuming process,” added the company’s Managing Director, Dr Matthew Dingle.

“The project outcomes have also contributed to our FormFlow Living business, which designs, develops and manufactures high-value, affordable modular housing using innovative building systems.

“To scale up FormFlow Living’s delivery model, we will soon offer the building systems to customers under license and are also establishing our first regional manufacturing hub in South West Victoria later this year.”

FormFlow was established in 2016 to commercialise a technique to bend corrugated metal at certain angles, without damaging the material’s structure or coating.

Last year the company won awards including the Advanced Manufacturing category at the Australian Technologies Competition, a Best in Class award at Good Design Awards Week, and overall winner in the Australia By Design TV series on Network 10.

Picture: supplied

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos