Pfi partners with distiller to test its unique titanium filtration system

One of the world’s largest spirit producers has partnered with Queensland manufacturer Products for Industry to adopt the company's small bore thin walled titanium membranes to replace existing filtration systems, initially for whiskey.

The company has also received its first orders from one of the worlds largest snackfood companies for systems to improve the quality of their processing oils.

Managing Director and Group CEO of Products for Industry (PFI) Gavin Dunwoodie told @AuManufacturing that the spirit producer, which he declined to name, intended to roll out the filters globally should tests prove positive.

PFi claims the world's only 100 percent titanium filter membranes only .35 of a millimetre thick, which offer longer filter life, can be steam sterilised, are corrosion resistant and process liquid streams containing fat, oil and grease among numerous benefits.

Dunwoodie said: “This is PFI’s most exciting innovation to date.

“The company has invested millions of dollars in plant and process to progress the technology and we have a list of international clients who have waited patiently for the membrane to be available.”

Dunwoodie said that the technology promises to give results unlike any current filtration technologies available on the global market, and was ‘almost completely non-perishable'.

Being metallic, the membrane can be electrically grounded and does not impart any flavour or aroma, requires no chemicals and operates at any PH and a full range of temperatures.

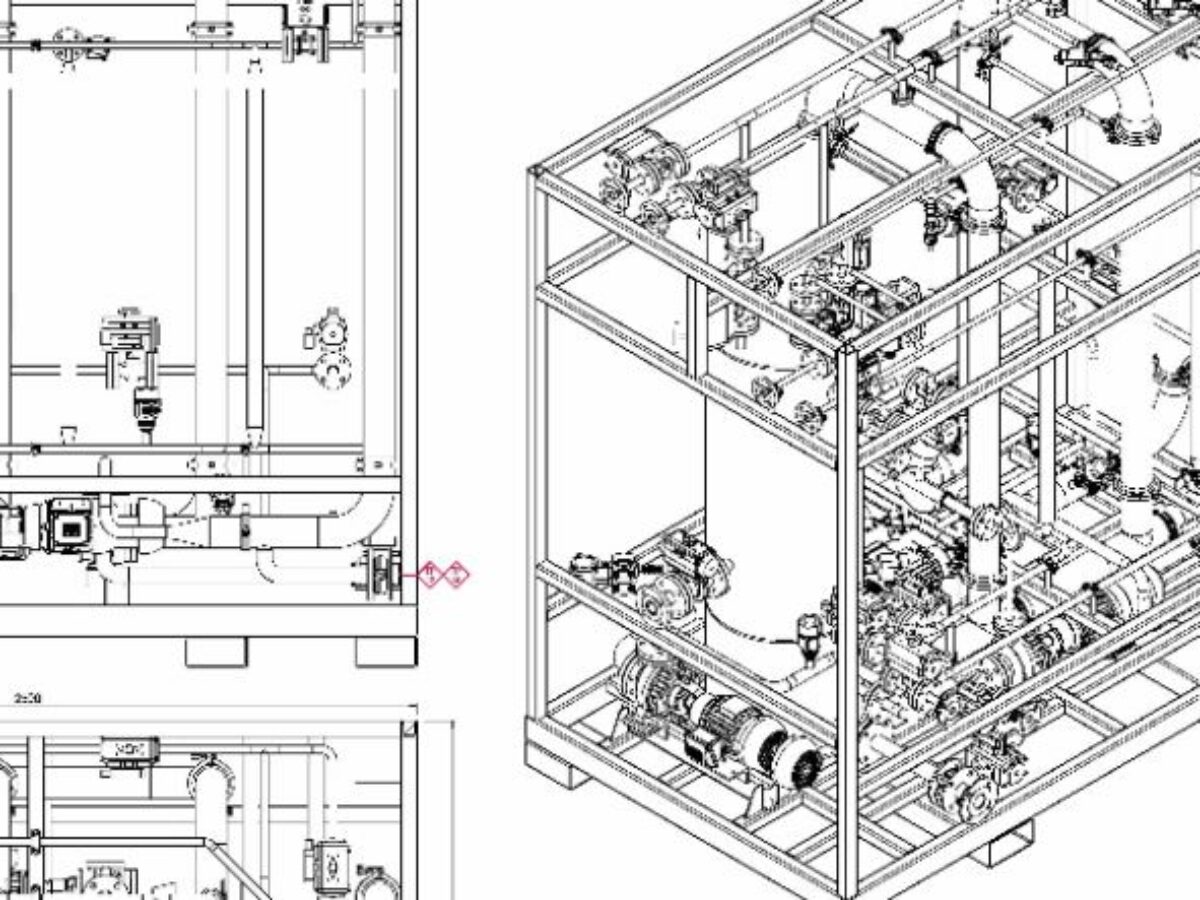

He released a diagram of a titanium membrane filter (pictured) which had a nominal flow rate of 1400ltr/hr filtering to less than 1 micron.

PFI has ordered two more custom furnaces to sinter the membranes to complement its existing factory in Darra, Queensland.

Image: Products for Industry

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos