PPK bets big on BN nanotubes

Diversified technology investment group PPK has reported on a year of transition from a manufacturer of mining equipment to a technology investment group with a heavy focus on developing new uses for the material boron nitride nanotubes (BNNTs).

The company completed a strategic review in the year and plans to demerge the mining equipment business through a separate stock exchange listing or sell it outright.

While affected by the Covid-19 pandemic, the mining group nonetheless developed a next generation underground mining coal tram, a 12 seat personnel vehicle and agreed to collaborate with Hunter Valley engineering firm Ampcontrol to install its electric vehicle technology into PPK mining equipment.

Meanwhile PPK's wholly owned BNNT Technology has ramped up production of boron nitride nanotubes and is now capable of producing 200kg per annum of 95 per cent pure BNNT in a single weekly shift in semi-automated mode.

A further expansion will add 300kg production capacity when commissioned next year.

The first use of BNNT's which has passed through PPK's technology incubation stage, Li-S Energy, raised $34 million in the year in preparation for a stock exchange listing.

The Li-S battery utilises boron nitride nanotubes to improve performance, and will be manufactured at a plant to be constructed in Geelong where PPK's R&D partner, the Institute for Frontier Materials at Deakin University is based.

Other PPK BNNT ventures include:

- White Graphene Limited is installing manufacturing equipment to make its transparent material known for its thermal conductivity, electrical insulation, radiation shielding and strength.

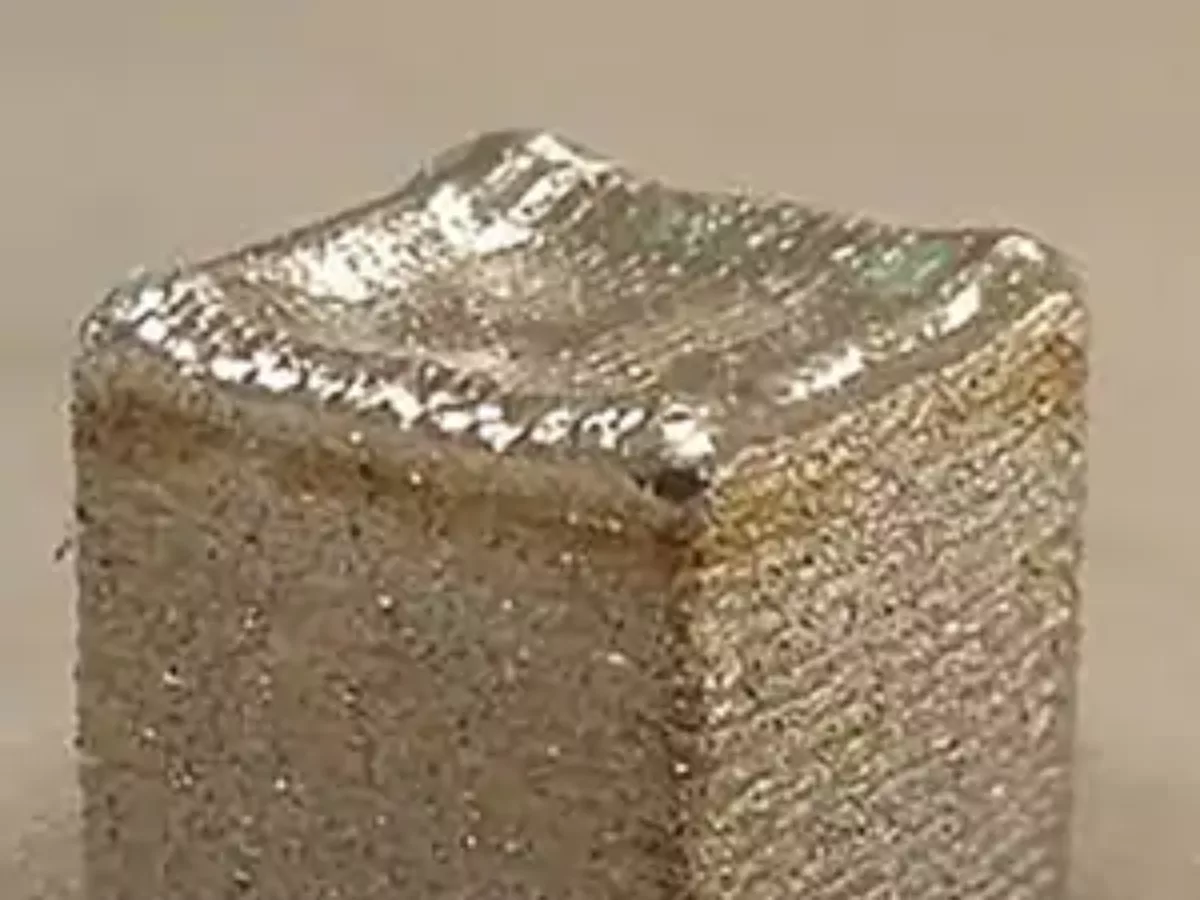

- The Strategic Alloys venture with additive manufacturing group Amaero International is developing super strength metal aluminium and magnesium alloys strengthened with BNNTs.

- And 3D Dental Technology is blending BNNTs into dental ceramics to lower the risk of dental implant failure.

PPK ended the year to June 30 with a reduced loss of $5.6 million

Picture: Institute for Frontier Materials/3D printed BNNT

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos