Pressure and performance: Australian company pushes to be a global leader in armour

Last week, listed defence supplier Xtek (ASX:XTE) announced it would buy a small protective equipment company in the US, HighCom Armor Solutions. This earns the Australian business distribution in the world's biggest defence market, and a path to becoming “a leading ballistic armour player globally.”

Brent Balinski speaks to Xtek’s managing director Philippe Odouard about the company’s curing process – which it says can produce lighter, stronger composite parts – and its potential applications in defence, space and elsewhere.

@AuManufacturing: Please give us a little summary of what you’ve been up to since you started heading Xtek in late-2016.

Philippe Odouard: In the last two and a half years now, or a bit more, maybe, I've tried to change a few things. The company has traditionally been an importer of defence goods, mainly equipment for the soldier, which is our specialty, really. And the purpose here was to get new products, our own products into the fray. Representing people from overseas is not necessarily very lucrative. If you do really well, they set up their own shop. If you don't do well, they kick you out. So that's not a very good job, especially if you're listed on the stock exchange, which is our case.

So the purpose was to try and develop our own products and launch them not only in Australia but worldwide. I've got that sort of experience. It doesn't mean that we dropped the traditional business. We kept on working, we signed a big contract for small drones for defence that we've been delivering steadily since then. And the company has grown very nicely, still mainly on imported goods.

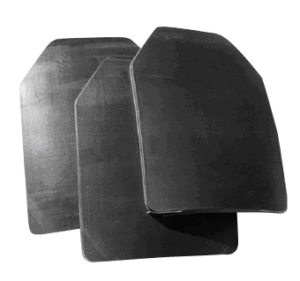

Small arms protective insert armour plates (Picture: XTEK)

Last year we did $17 million, the year before we did $9 million. This year will finish at around $35 million. So $9 million, $17 million, $35 million, that's a good progression. The main thing that we did was work on our new products and we have focussed on two of them.

One is a software product that takes full motion video from drones. So trying to do things very complementary to what we normally do. You don't change things completely, you just build up on things that you know best. And so we take full motion video from a drone. For small drones, if you fly very low about 50 metres from the ground, you basically have a glimpse of what's happening, the ground is going by very fast and you can't really spot very much. It's very hard to see very much. So what we do is create maps on the run. So you do a lawnmower pattern and are basically creating a realtime map, which gives you a much better visibility of what's going on. We have tools to compare this with previous maps that would have been produced before, and that can see how the situation has changed. And it's a very, very powerful tool for the war fighter.

We have developed that particular software. We're now proposing it to a number of countries. We've sold it to a certain extent at smaller quantities in Australia and overseas. And that is picking up very nicely. Very unique, no one seems to have thought about this, but we looked at it from a perspective of what does the customer want, and how can a drone help him? And we thought, drone manufacturers tend to look at it from the aircraft perspective. We looked at it from the mission perspective.

But the other one, which is linked to the announcements that we've done this week, is a bit different. We've been working on a process to make ballistic products, that being plates to defend against bullets, that you put in a bulletproof vest and helmets.

@AuManufacturing: This is XTclave?

Philippe Odouard: Exactly. It's a process, but you don't sell a process, you sell a product. We have been developing that particular process nicely. We are basically finalising a large machine that will be an industrial machine. We're finalising the setup of the factory as well.

In parallel, we develop products because the process allows you to do a number of different products, at different levels of protection for different kinds of threats, different kinds of rounds. And we developed plates as well as helmets. A typical helmet would protect you against a 9 mm pistol, but not against an AK-47 round. Our guys are typically deploying in areas where the threat is AK-47, not pistols. So that's what we've developed.

I mean look, it's not that simple. Lots of people have tried and couldn't do it. Our process is actually very well suited for very complex shapes and a helmet is a lot more complex than a plate. So we've been successful, we've demonstrated that to one of the bodies in the US Army recently. So it's actually looking extremely good.

@AuManufacturing: Could you say a little about the origins of XTclave? I think it's interesting that you've moved on to another company that's commercialising a very high-potential curing technology. Was XTclave a university spinout or developed in-house in your Adelaide R&D Department?

Philippe Odouard: No, it's really our Adelaide R&D Department. There was a couple of guys out of DSTO, DSTG it’s called now, and that started a while ago. That was simmering in the background and it needed to be taken out of the lab into the real world. And that's really what I did. And you know how it works in R&D, you tend to have scientists that are brilliant, but they can always improve their invention, it's never really ready for market. [Laughs] So to really say, “Well, hey guys, that is good enough for what we can do, let's launch this, and if you want to continue working on the next generation please do so.” And it's going to be better, of course, but if you're broke before that, it's not that useful. Pretty much used to that kind of attitude in the past and we had the same problem in Quickstep, actually.

@AuManufacturing: It's been a long journey for their clamshell process. As impressive as it is, it’s not been a gigantic commercial hit. or at least not yet.

Philippe Odouard: I won't comment on that. Interestingly, the process that we're talking about here is actually, in a way, a bit like Quickstep, if you like, except the Quickstep one was low-pressure. What we do here is an ultra-high-pressure system. It looks like an autoclave, but instead of filling it up with a gas, you fill it up with a liquid and the liquid allows you to get to very high pressures and then you need to circulate the liquid into the pressure vessel and heat it up to consolidate.

So the principle is quite simple. The reality of how that can work properly, to circulate the liquid at 300 pounds is not exactly the simplest thing. Not circulating it is not a possibility either: you won't know exactly what you've got.

So it took us a fair while to get that running. But, but it runs really well. We've actually sold one of our machines previously, running at much lower pressure – it was 100 bars only – to a licensee. And these guys have made several hundred thousand plates that they sell across the world. So it's not exactly new or unproven technology. What we've done is we've considerably improved the pressure, which gives you a better result, and we've improved the cycle speed. We have cycles of about an hour and 20 minutes when the previous machine that had basically a cycle of about four hours.

Picture: XTek

@AuManufacturing: We saw news last month that you received a CDIC grant to help with commissioning a new production line for XTclave. Can you tell me what that will involve and what the timetable for this looks like?

Philippe Odouard: We had some delays, which is not not abnormal in this kind of industry. We forecast to have that ready by the end of the calendar year. The pressure vessel has just been finished. It's about to be shipped now. A lot of the sub-elements are now on order. They've been fully designed, we’ve done a full detailed design review, and are on order from manufacturers of different kinds for different components. The whole thing should be together in about October. So we start to get into the detail of the assembly and installation rather than in the principles of the design. So that is looking pretty good. We should be up and running towards the end of the year. Probably have a global slow ramp-up during the first six months of next year. And that should be full blast by March, April next year.

@AuManufacturing: We're speaking because of the HighCom acquisition through the week. Could you tell us about how important this is in getting your armour products to an international audience?

Philippe Odouard: We are reasonably good at selling these products in Australia, but the XTclave and these products have international importance. The expansion there is going to come from exports.

So we've been looking at different markets. The one that comes immediately to mind is the biggest in the world, which happens to be the US, and how do you break into that market? The Australian market is very different from the US, so we needed a partner or an acquisition.

The other thing that was very important is that if you want to reach the military side, which is the by far the biggest, we needed manufacturing there. So an opportunity presented itself about six months ago. We worked on it for that duration and it led to this acquisition.

So what is HighCom? It's a $10 million company roughly. They have their own products, they have their own manufacturing, they have their own distribution networks. Most of what they do tends to be police. You have 18,000 police forces in the US. 800,000 policemen. So that's a big market just on its own. Like any police, they tend to be not very rich and they tend to buy things that are not too expensive. These guys are positioned in that sort of market, because their products are not fantastic in terms of weight in particular.They do what they're supposed to do of course. They're heavy, typically, but cheap.

So that's a fantastic entry for us because we bring new products, we bring lighter products, we bring them capacity to get into more sophisticated parts of the market, in defence. But also everything we do is suitable for police and works fantastically. So the combination of both is actually extremely valuable.

So that's why we did it. We acquired it for a multiple of 2.6 which is very inexpensive. Not that the vendor was particularly unaware of the value for us, but because we pay them partly in shares of Xtek and we expect the value of the combined entity to increase.

So it's a win-win for everyone and I think it's a great adventure. It really positions us very nicely in the US market with their manufacturing entity. It’s an accretive acquisition right from the start and it will give us a position on the world market, which is going to be massively, massively interesting. So that means if we say, “We'll send that to the US,” guess what the Europeans are going to say? They'll want it as well. So it's a very, very good start.

@AuManufacturing: Would you be sending an XTclave over there or would you be exporting armour?

Philippe Odouard: We'll be making one and then send it to them probably in about 12 months time. But in the interim we'll probably supply them plates out of Australia, especially for the police market – you can import these plates. They have that network already available, that means as soon as we can produce, we'll be able to sell, and with very short delivery times – three to six months.

@AuManufacturing: Lastly, we wanted to ask about your recent deal with Skykraft. Could you tell us about your space industry ambitionsand if you see that as something that holds a lot of potential for your curing technology?

Picture: www.calliduspr.com

Philippe Odouard: It's probably a bit longer term. There's a lot of hype at the present time with the 50th anniversary of the moon landing. [Laughs.]

Frankly, when we started on that journey, we didn't know that this would make that much noise around the place. The fact is that that particular technology I described, the hydroclave, is actually very good for space applications. Three reasons for that.

The first one is that it actually allows you to make very complex shaped parts. Whereas most of what you do normally in carbon fibre you really need to do shapes that have only mild curvatures. Because we have that massive pressure, we can actually do very complex parts and not even have to adjust them or mill them or do any other processes. So for space, it's interesting, because when you talk about aircraft, you want these semi-flat parts, but for a satellite no one cares. So in that case you have a lot of these parts that are complex in terms of shape.

The second advantage is that because you have so much pressure, you can actually do a higher level of fibre compared to matrix. What gives you the strength is the carbon fibre, not the matrix, which is there to keep it together. The maximum you can do typically in the fibre ratio in normal carbon fibre is about 60 per cent fibre, 40 per cent matrix, so we believe we can get to 75 per cent and possibly even 80 per cent, so that would reduce your weight by about 20 per cent. For space it's massively interesting.

And the third one is a particular thing that happens in space. Because you have no air around and no pressure around you, if you consolidate or cure things in an autoclave for instance, which is what is used normally, you'd very quickly have bubbling. You'd have the volatiles basically getting back into their normal shape and then bubbling up, which is called degassing. If you do that compression at 300 bars, degassing is just not happening. So for space, it's really, really important, especially if you have things that are staying there a long time. You don't want pitting in your parts as you go.

When we explained that to a few people, and Skykraft in particular, they were very interested.

We've gradually started talking to other people that are in that space industry and you might continue following us on that because more news is going to come. It will probably take time. But on the other side, space is actually becoming a lot more democratic. You have smaller launches, smaller satellites, more applications, lower costs of course with the competition that you have with the private entities like SpaceX and others. So all this is a booming industry that is coming up and we think we have something very unique for them.

Featured image: Lighthouse Business Innovation Centre/Youtube

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos