RMIT research doubles fly ash content in low-carbon concrete

Researchers from RMIT University have shown evidence that a new concrete they’ve developed can repurpose twice the amount of coal ash currently used versus current standards, with benefits in performance and lower volumes of cement required.

According to a statement from the university, research in collaboration with AGL's Loy Yang Power Station and the Ash Development Association of Australia has substituted 80 per cent of the cement in concrete with coal fly ash.

Over 1.2 billion tonnes of coal ash were produced by coal-fired power plants in 2022, and it represents almost a fifth of all waste produced in Australia. At the same time, cement production contributes about 8 per cent of global carbon emissions, with demand for concrete (featuring cement as a key ingredient) tipped to continue growing.

RMIT project lead Dr Chamila Gunasekara said the team’s new concrete is a significant advance, with existing low-carbon concretes typically replacing only 40 per of their cement with fly ash.

“Our addition of nano additives to modify the concrete’s chemistry allows more fly ash to be added without compromising engineering performance,” Gunasekara explained in a statement.

Lab studies have also shown the team’s approach can repurpose lower-grade and underutilised “pond ash” from coal slurry storage ponds “with minimal pre-processing”, and large concrete beam prototypes made to Australian Standards for engineering performance and environmental requirements.

“It’s exciting that preliminary results show similar performance with lower-grade pond ash, potentially opening a whole new hugely underutilised resource for cement replacement,” Gunasekara said.

“Compared to fly ash, pond ash is underexploited in construction due to its different characteristics. There are hundreds of megatonnes of ash wastes sitting in dams around Australia, and much more globally.”

The statement from the university adds that computer modelling developed in partnership with Hokkaido University has been used to forecast the time-dependent performance of these new concrete mixtures. The results of this were published in Cement and Concrete Research.

Gunasekara said that the results show the quick-setting nano-additives “significantly [enhance] the material by increasing density and compactness” and “act as a performance booster during the early stages of setting, compensating for the large amounts of slower-setting fly ash and pond ash in our mixes.”

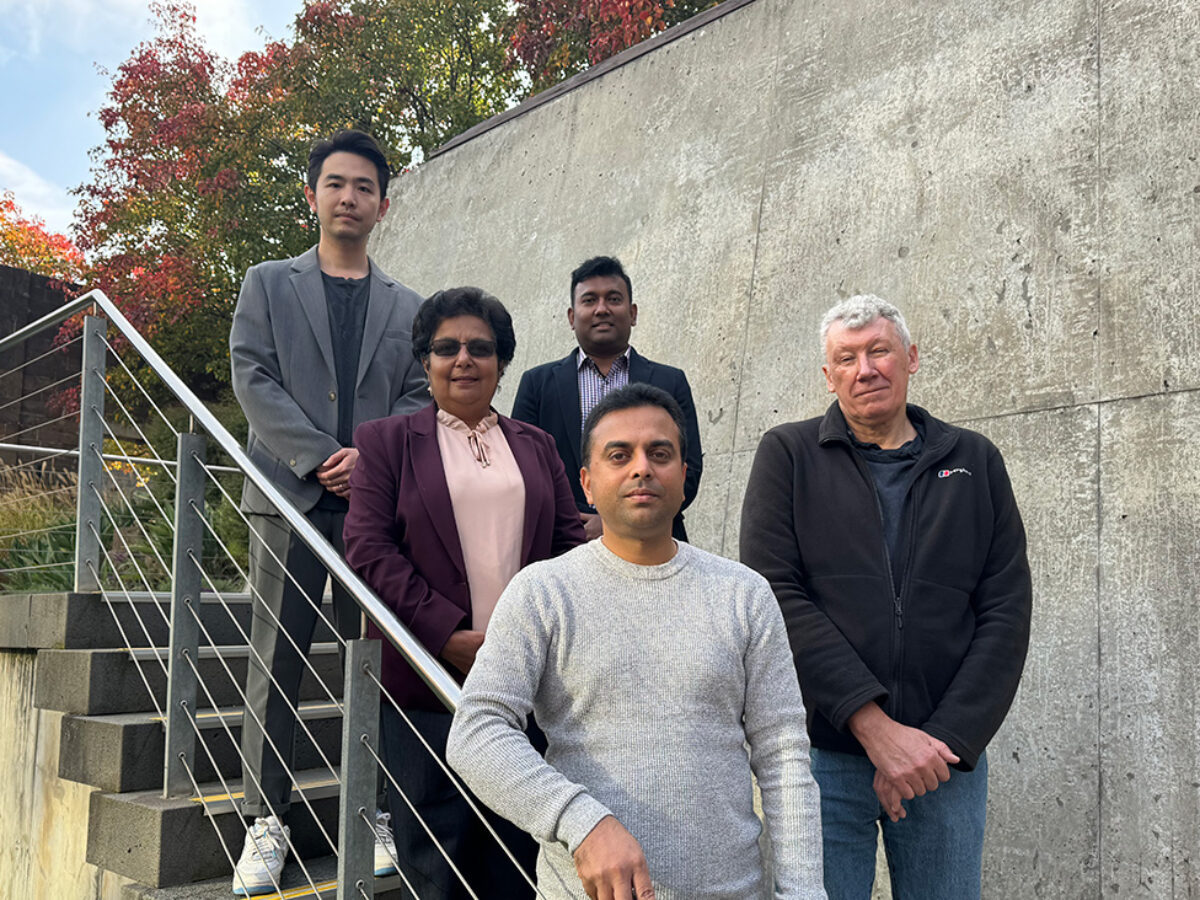

Picture: Dr Yuguo Yu, Professor Sujeeva Setunge, Dr Dilan Robert, Dr Chamila Gunasekara, Dr David Law (credit Michael Quin, RMIT)

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos