Seeley wins major meat works air con project

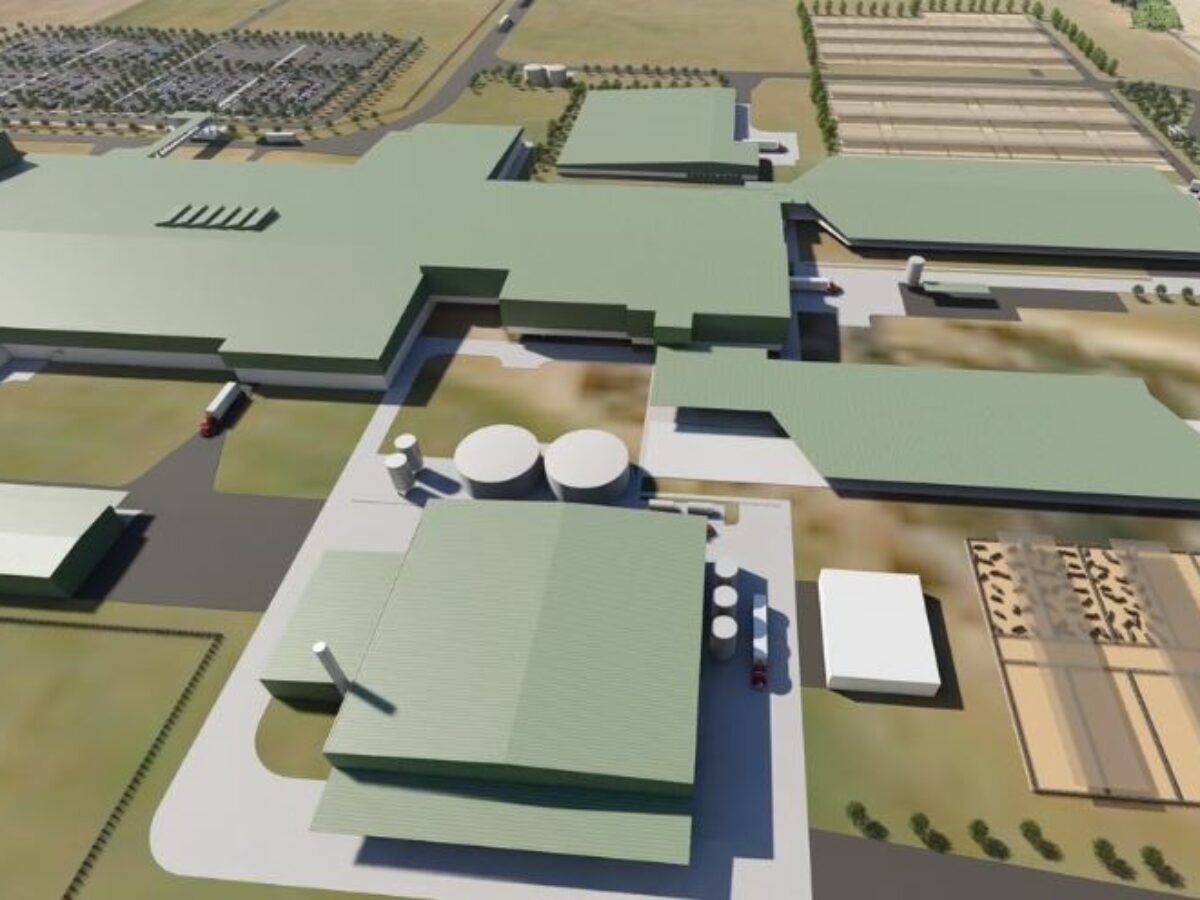

Australia’s largest air-conditioning manufacturer, Seeley International, will utilise its unique indirect evaporative cooling products to provide the HVAC system for Thomas Foods International’s new Murray Bridge meat-processing facility in South Australia which will replace one destroyed by fire.

Seeley will provide its Climate Wizard indirect evaporative cooling systems (IEC, below) for the project which are capable of cooling fresh air to temperatures only previously possible through more complex and energy consuming refrigerated systems.

Seeley has been making inroads into fast food and major food and beverage processing with its Climate Wizard, but its use in the meat works touted as a ‘global showcase of advanced food manufacturing’, will be one of its largest installations to date.

Thomas plant will have an initial beef processing capacity of up to 600 head of beef cattle per day, but will eventually involve hundreds of millions of dollars investment and employ 2,000 when complete.

Seeley’s group managing director, Jon Seeley said: “We are exceptionally proud to be partnering with Thomas Foods, which has very strong sustainability and health mandates – these are really what our technology espouses.

“Particularly in the commercial world, we are seeing the convergence of sustainability and health, with the growing challenge for buildings being the efficient delivery of fresh, outside air”.

Seeley’s Climate Wizard technology has been deployed globally because of its efficiency but the fact that it delivers only fresh air, unlike refrigerated systems, is important for health and air-flow requirements in meat processing.

Meat processing has been a high risk area for the spread of the Covid-19 virus.

Seeley will partner with other South Australian companies such as BADGE Constructions and Ahrens Steel to deliver the project, of which the first stage is set to be complete by late 2022.

Pictures: Thomas International Foods/Seeley International

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos