Space Tank wins prestigious Good Design Award – a case study by Rodin Genoff

Company incubator Space Tank has won the prestigious Museum of Applied Arts and Sciences (MAAS) Good Design Award for its Rapid Shield face shield personal protection equipment (PPE). Part of North Melbourne's Assistive Technology Cluster of firms created by Steve Zanon, founder of Proactive Ageing, Space Tank fast tracked the design and production of the shields. Rodin Genoff explains in this special case study.

Space Tank Studio, Australia's most innovative makerspace, answered the call from government to supply personal protective equipment when the Covid-19 pandemic hit.

Holger Dielenberg and Scott Anderson wanted Space Tank's new design department to be of service to everybody in the community who needs health PPE.

Anderson said: “When lockdown number one hit we asked ourselves how we can put our prototyping technology and design smarts to good use?

“The support we received from Steve Zanon and the Assistive Technology ecosystem helped us fast track the design and commercialisation of face shields.”

This is where their remarkable six week sprint sprint to collaboratively develop and supply the Rapid Shield (main picture) begins: Holger and Scott the maker alchemists, and Steve the orchestrator, connecting businesses and opening doors.

The Covid-19 pandemic exposed Australia's supply chain vulnerability and the collaborators seized the moment to conceive, design and manufacture in Australia.

Zanon said: “How could Australia let itself come to this, where we can't even guarantee the safety of hospital staff, let alone the broader community?”

Zanon's assistive technology cluster brings together manufacturing and the aged care industry and was ready for the challenge.

Space Tank collaborated with Roland Gesthuizen who led a brains trust of STEM educators and academics. They sourced up to date information on health PPE and opened links with staff at Monash Health in Melbourne.

Next Space Tank became registered under the Therapeutic Goods Act within the space of three days.

Then the design process began, with Space Tank taking existing folding concepts for face shields and putting them through a design for manufacturing optimising process to remove bulk from the folding points, eliminating the need for buckles, screws and foam padding.

Holger said: “We solved pain points across the whole value chain, including design efficiencies and zero waste manufacturing methods, with the end product being recyclable.”

Then Holger was led to Signum, a leading food packaging company which was able to adapt its existing production configuration to manufacture up to 250,000 face shields per week.

Anderson said: “With Signum's high volume capability we were able to be very competitive against the Chinese price point. It gave us the manufacturing edge we needed.”

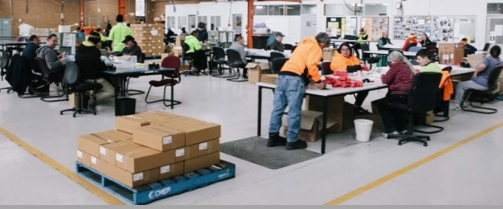

Finally the Assistive Technology Network turned to Brite Disability Employment Services (picture, below) to pack Rapid Shields, creating new employment for disabled workers.

Now Space Tank is selling Rapid Shields around the country to schools, disability and aged care facilities, GPs, speech pathologists, hair salons, beauticians, retailers and medical clinics.

Holger said: “We saw 20-fold increase when Lockdown number two was announced.

“Sales consistently ramped up by 10 per cent a week and now that we are supplying retail outlets around Australia, we expect we will reach a tipping point in our third month of operation.”

Pictures: Space Tank/Rodin Genoff

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos