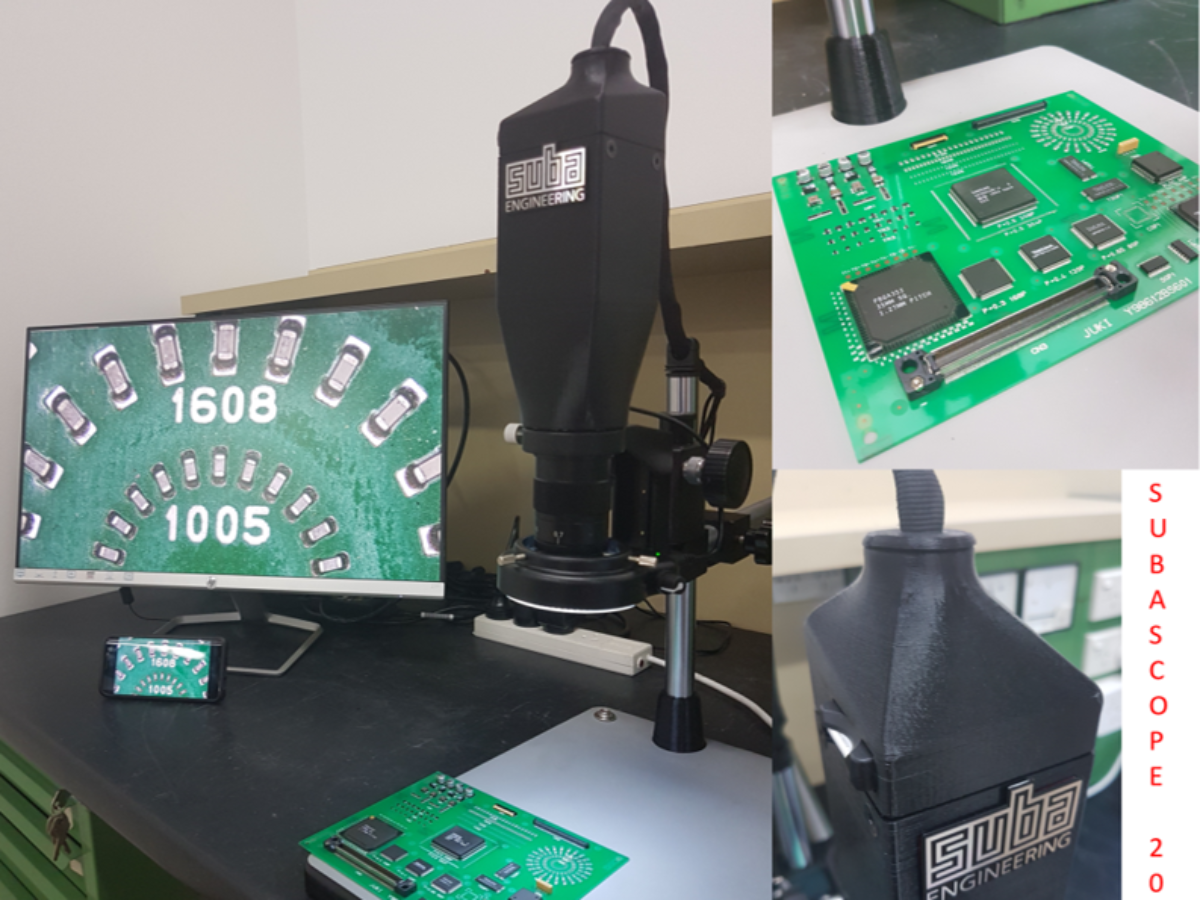

SubaScope digital microscope outperforms imports

Sydney's Suba Enginerering is poised to launch an upgrade to its successful SubaScope digital microscope used for inspection in electronics manufacturing.

The company, which launched its first locally engineered and made microscope in September, has added new features and retained the same low cost that has seen it sell more than 200 systems in only four months.

Suba's owner, Heinz Zimmerman told @AuManufacturing the SubaScope has been an instant hit with sales in the USA, Germany, Switzerland, Singapore and Thailand.

“What we do we buy all the standard parts at good prices and add our smarts to it.

“The price is very competitive, and even in Asia they are amazed at the price performance of our SubaScope out of Australia.”

The latest SubaScope, which has undergone site testing, features automatic focusing, Bluetooth mouse, built in software and a Micro-SD card to store pictures or video.

Suba employs 15 people in its Sydney and Melbourne operations, and as well as upgrading the SubaScope, is developing its own laser marking machine.

“We are more and more working on making Suba products for our customers as new technology in manufacturing is making things easier,” said Zimmermann.

For three decades Suba has been known as an importer of equipment for electronics manufacturing, but it developed the SubaScope to fill a gap in the market for a quality, low cost product.

To make the $1,800 SubaScope the company combines off the shelf digital cameras and ring lights with parts mainly sourced from Asia or made on its own 3D printers.

“My dream and vision is to also be a manufacturer of equipment,” said Zimmermann.

“The SubaScope is our first step.”

Picture: Suba Engineering/SubaScope

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos