The future of manufacturing is garbage

By Dr Jens Goennemann, Managing Director, Advanced Manufacturing Growth Centre

A while ago I blogged about Viridi, a clever bunch that is developing a way to salvage grape sugar, tartaric acid and antioxidants from wine waste.

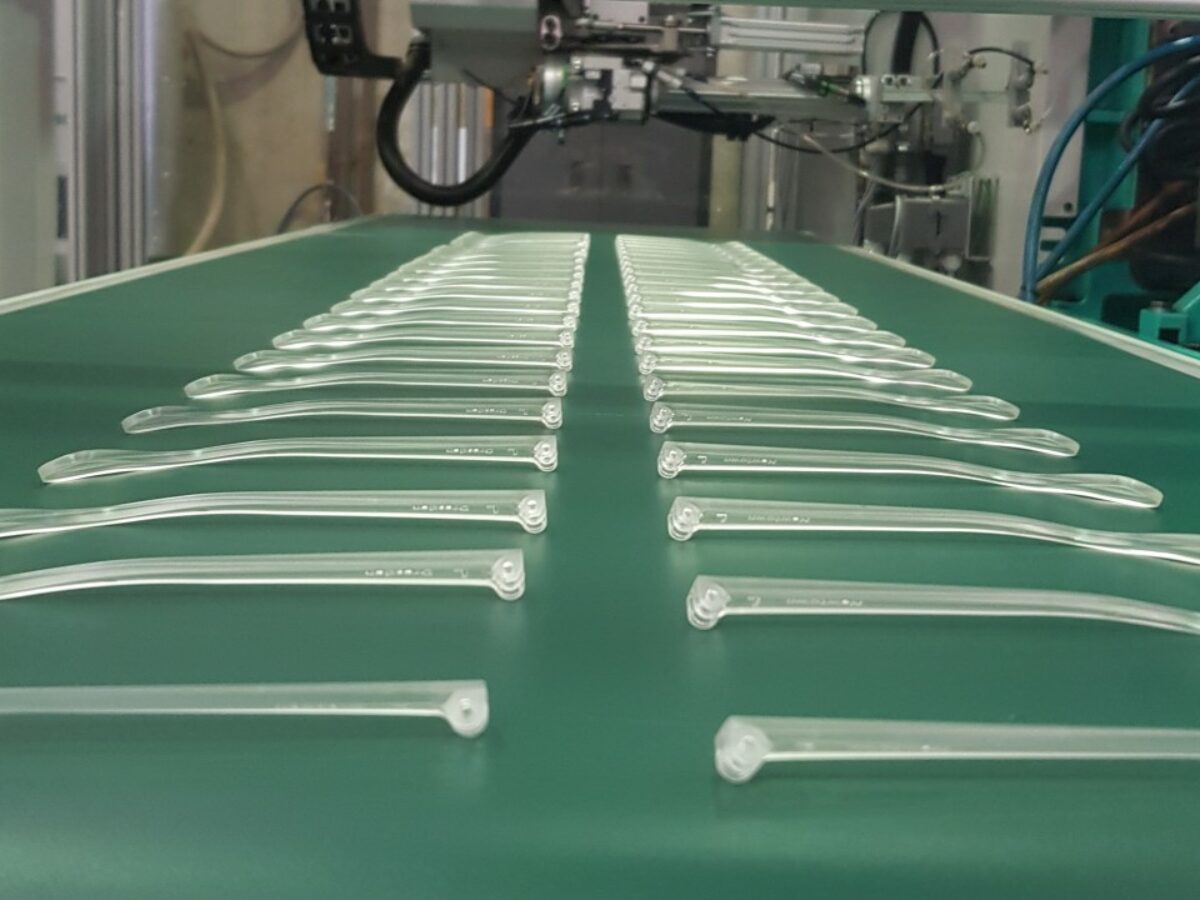

The Advanced Manufacturing Growth Centre has also supported work by Dresden Optics, helping them automate and scale up production, in collaboration with Consonic, University of NSW and others. They’re using things like reclaimed fishing nets and beer keg lids to make eyewear and aim to one day use 100 per cent recycled plastics as their feedstock.

Why am I mentioning wine and spectacles? It’s because these two manufacturers are part of an interesting current trend.

Beyond our shores, Adidas has committed to completely phase out virgin polymer by 2024. It intends to make 11 million pairs of recycled shoescontaining recycled plastic this year, in collaboration with Parley for the Oceans. We recently saw news that a new Swedish bike manufacturer, in collaboration with Nestle, is making high-end rides out of aluminium from Nescafe pods.

In case you hadn’t guessed already, what we are talking about is the ‘Circular Economy,’ a topic that seems to be everywhere at the moment.

In simple terms given by the Ellen Macarthur Foundation, the concept is based on three principles:

● Design out waste and pollution

● Keep products and materials in use

● Regenerate natural systems

It might have hippy connotations for a few, but Circular Economy is about some pretty old, common-sense ideas – minimising waste and getting the most value out of the resources that have been paid for. This is the stuff of Manufacturing 101.

The concept aligns nicely with Advanced Manufacturing, and we have seen our Man-In-A-Suitcase Michael Sharpe at a tonne of Circular Economy events lately. He brings back to us that manufacturers are interested, but there’s some uncertainty around how exactly to proceed.

For inspiration’s sake, let’s share a couple more examples.

Downer and others are turning waste into road surfaces. 530,000 plastic bags, 168,000 glass bottles, 12,000 toner cartridges and 135 tonnes of recycled asphalt go into every kilometre of two-lane road.

The work of Professor Veena Sahajwalla, founding director of University of NSW’s award-winning Sustainable Materials Research and Technology (SMaRT) Centre, is another high-impact example. She is the inventor of “Green Steel” process, in collaboration with OneSteel and then MolyCop.

Green Steel, or Polymer Injection Technology, uses old tyres as a substitute for coke for the carbon used in steelmaking. This has saved millions of tyres from the tip so far. An estimated 56 million passenger car tyres are thrown out by Australians every year, with only a tenth of these reused. Given these huge quantities and the slowness of tyres to break down, Sahajwalla’s work has obvious appeal.

It’s no coincidence that each of these projects is a collaborative one. Manufacturers, researchers, waste collectors and others must work together for Circular Economy initiatives to succeed.

Australian governments will soon set a total ban on exporting recyclables. Given this, smarter use of our waste can only become more important. There are opportunities for smart manufacturers to step up.

Let economy make ecology work.

Follow Jens on Twitter

Picture: Dresden Optics Spectacles Production Line

This article originally appeared here. It has been republished with permission.

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos