Think strategically about operations and supply chains- by Mohsen Varsei

Mohsen Varsei takes a look at the parlous state of Australian manufacturing. He argues the answer is to refocus on operations and supply chain excellence. This sets new business horizons and becomes the manufacturing firm's advantage.

The government recently acknowledged that ‘manufacturing in Australia has stagnated.

Not enough manufacturers are scaling-up’. Its ‘vision is for Australia to be recognised as a high-quality and sustainable manufacturing nation that helps to deliver a strong, modern and resilient economy’.

To reach this vision, companies need to think strategically about their operations and supply chain.

Factory Closure: People Feel Gutted

Overall, the manufacturing sector in Australia has the potential to do better, particularly when we compare it globally. For example, we can consider a country of similar size and economy: Canada.

According to recent data, Canadian manufacturers export more than $354 billion, representing 68 per cent of all of Canada’s merchandise exports. Australian manufacturers export $54 billion, making up only 11 per cent of Australia’s total exports which are heavily concentrated in natural resources for one or a few markets.

This low diversification is risky given geo-political dynamics in the region. What if an export market stops buying Australian resources (e.g. coal) or service (e.g. international students); what if a black swan disruption happens (e.g. COVID-19)?

Canadian manufacturing sector creates ‘1.7 million quality full-time, well-paying jobs’, while ‘full-time’ manufacturing jobs in Australia are around one million less. Given the average household size of 2.6 in Australia, one million jobs could mean a better life for 2.6 million Australians. This is a big gap which can be filled by a world-class manufacturing sector.

We have all felt the decline of Australian manufacturing, for example when a community was impacted by news like this: Toyota to close: Thousands of jobs to go as carmaker closes Australian plants by 2017.

Some research says that factory closure ‘resulted in highly visible redundancies amongst the vehicle producers, and a more profound, but less noticeable, loss of employment within the supply chain’.

We know that losing job is not an easy thing. People ‘feel gutted’. They cry, silently.

Scaling-up by Operations and Supply Chain Strategy

But we can reverse this decline. Australia can and must do better for various socio-economic reasons.

What we can learn from operations and supply chain management research can help us, for example, by showing how other nations experienced manufacturing decline, and the roadmap to revitalise the sector and become world-class.

Wickham Skinner, a Harvard Business School operations management academic, was among the first to investigate the ‘decline of American manufacturing’ in the late 1960s.

Attacking the conventional wisdom of the time, he argued that great marketing and finance were not enough for a business to compete globally. It needs to be good at operations, as well. It must have a strategic view of its operations.

Skinner’s 1969 article “Manufacturing – the Missing Link in Corporate Strategy” and 1974 book “The Focused Factory” developed a new concept used by several companies around the world: operations strategy.

This concept was further developed by his colleagues, Hayes and Wheelwright, who proposed a four-stage model for operations strategy. This model could be applied to both manufacturing and service organisations.

And, as globalisation has extended operations to global supply chains for many businesses, the model could (and should) be adapted to include supply chain:

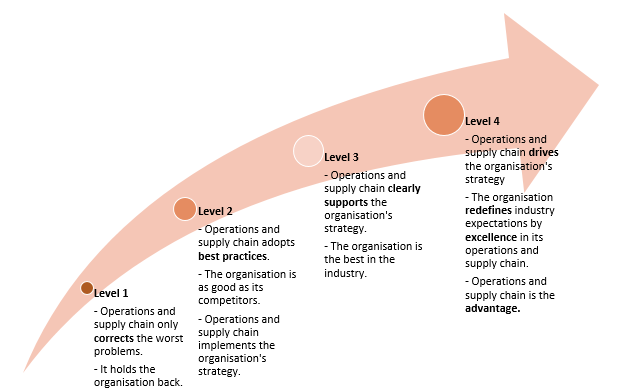

Figure 2: Maturity Model for Operations and Supply Chain Strategy (adapted from Hayes and Wheelwright cited in Slack and Brandon-Jones)

This model is an honest mirror in front of us, saying where we are and what the next levels for improvement are: if we reactively correct the worst problems, we are in Level 1.

It is fine to follow best practices, but then we are only one level above the worst (i.e. Level 2).

When the organisation’s strategy is clearly linked with the operations and supply chain, we are in Level 3.

At the highest maturity level (i.e. 4) the operations and supply chain drives the organisation’s strategy.

Operations and supply chain excellence helps the business redefine industry expectations and set new horizons. It becomes the advantage. Global businesses like Apple, INDITEX (Zara), IKEA, Nike, Tesla and Amazon (e.g. watch this presentation by its supply chain executive) share the characteristics of Level 4.

Let’s Re-think Together: Few Questions

Now the first question worth exploring is: how many businesses and executives in Australia think, say and act in Level 4?

If we honestly reflect on our (often unnecessarily) long board memos, committees, reports, and most importantly on facts (because they are often misinterpreted and lost in words), I think the answer is ‘very few’.

Even if the answer is ‘there are some’, we can and should have more.

Founded in 1976, in August 2020 Apple Inc. reached $2 trillion market cap. We don’t buy Apple (or Samsung) phones because of national pride or government subsidy or pressure; the product must sell itself in the long run.

And if it does this well, the reward for a world-class business is huge: the global market. According to European Union, the ‘global middle class is expected to grow and reach 5.5 billion by 2030’.

Various technologies in the 4th Industrial Revolution, digitisation and digitalisation have made global markets much more accessible.

The world’s most valuable car company, Tesla, sells its car online, ‘no car salesman’. Tesla has redefined industry expectations by innovative processes, operations and supply chain (see Level 4 in Figure 2).

The second question worth exploring is: have we educated managers in Australia well to think, say and act in Level 4 of operations and supply chain strategy?

In how many business schools in Australia we have a dedicated team of academics (similar to finance, human resource and marketing) who focus on operations and supply chain?

I hope I could be proven wrong, but to the best of my knowledge the answer is again ‘very few’.

Overall there are only few public (e.g. University of Melbourne) and private (e.g. Australian Institute of Business) providers in Australia which have a dedicated team for operations and supply chain education and particularly for executive education (e.g. MBA).

Only a few teach concepts like operations strategy to help Australian managers think and act in Level 4.

But this is not the setting in most leading business schools, for example in Europe (e.g. INSEAD, London Business School) and North America (e.g. Harvard).

And this does not represent today’s business world at all where we increasingly see Chief Supply Chain Officers and Chief Operations Officers on the board, even becoming the CEO (e.g. Apple’s CEO, Tim Cook).

As Harvard’s Skinner argued, great marketing and financial wizardry are not alone sufficient; we need strong operations (and supply chain) to build more world-class manufacturing (and service) businesses in Australia. Businesses like Tesla, like Apple.

We need managers who do not merely follow best practices and can think big in line with Level 4, strive for excellence in operations and supply chain and redefine industry expectations by a unique way of making products/services and delivering to customers around the world.

This story first appeared in AIB Review.

Dr Mohsen Varsei is Discipline Leader in Supply Chain and Operations Management at the Australian Institute of Business (AIB). He helps managers transform or improve their organisations by rethinking the operations and supply chain and its strategic impact.

Picture: Mohsen Varsei

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos