Researchers develop titanium alloys for 3D printing

Scientists form the University of Sydney and RMIT have developed a new class of what they call ‘designer' alloys made of titanium aimed at use in additive manufacturing processes.

By integrating alloy and 3D printing process designs, the alloys hold promise for more sustainable high-performance alloys for applications in aerospace, biomedical, chemical engineering, space and energy technologies. .

Their research in collaboration with Hong Kong Polytechnic University and Melbourne company Hexagon Manufacturing Intelligence was published in the leading journal Nature.

Co-lead researcher, University of Sydney Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer said: “This research delivers a new titanium alloy system capable of a wide and tunable range of mechanical properties, high manufacturability, enormous potential for emissions reduction and insights for materials design in kindred systems.”

The new materials consist of a mixture of two forms of titanium crystals, called alpha-titanium phase and beta-titanium phase, each corresponding to a specific arrangement of atoms.

While titanium alloys have traditionally been produced by adding aluminium and titanium, the researchers investigated the use of oxygen and iron – abundant and inexpensive elements that can act as powerful stabilisers and strengtheners of alpha- and beta-titanium phases.

Professor Ringer said: “The critical enabler is the unique distribution of oxygen and iron atoms within and between the alpha-titanium and beta-titanium phases.

“We've engineered a nanoscale gradient of oxygen in the alpha-titanium phase, featuring high-oxygen segments that are strong, and low-oxygen segments that are ductile (retaining its strength after being moulded into a narrow thread) allowing us to exert control over the local atomic bonding and so mitigate the potential for embrittlement.”

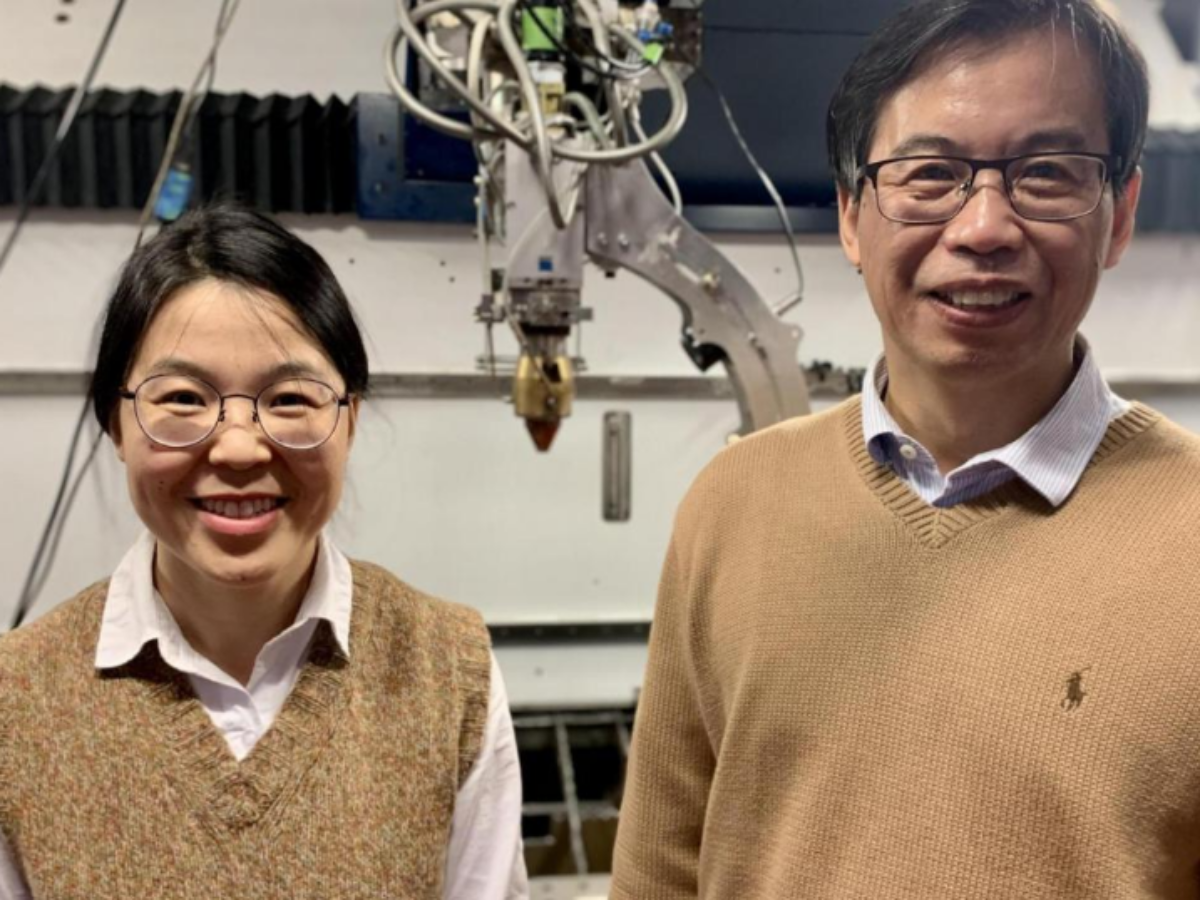

Lead researcher Distinguished Professor Ma Qian from RMIT (pictured) said the team embedded circular economy thinking in their design, creating great promise for producing their new titanium alloys from industrial waste and low-grade materials.

“Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry,” said Professor Qian from RMIT’s Centre for Additive Manufacturing in the School of Engineering.

According to the researchers, two challenges have hindered the development of strong and ductile alpha-beta titanium-oxygen-iron alloys – oxygen can make titanium brittle, while adding iron could lead to serious defects.

The team used Laser Directed Energy Deposition (L-DED), a 3D printing process suitable for making large, complex parts, to print their alloys from metal powder, developing a unique microstructure to rival commercial alloys.

The other lead author is Dr Tingting Song, RMIT Vice-Chancellor’s Research Fellow (pictured).

Picture: University of Sydney/Ma Qian and Tingting Song

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos