Uni Qld buys AML3D 3D printing system

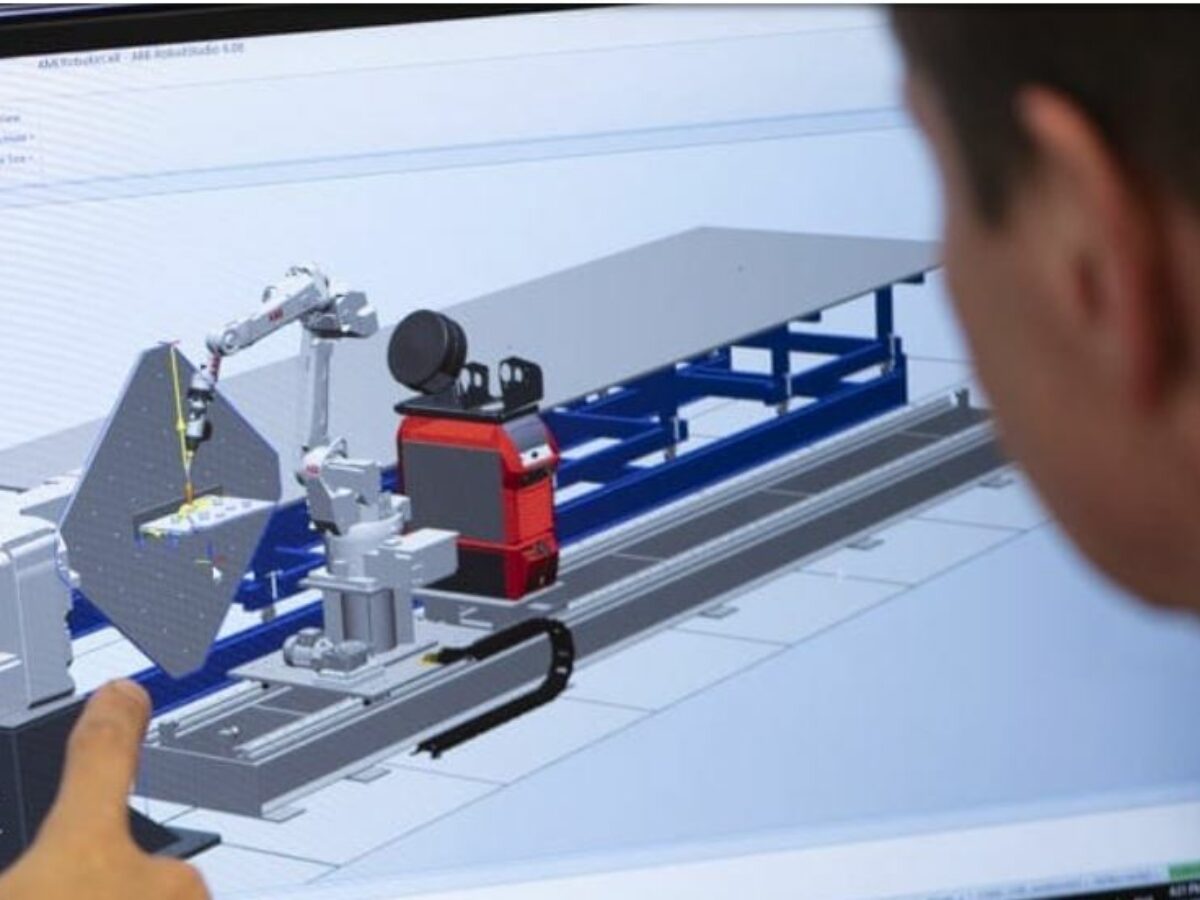

The University of Queensland has purchased an Arcemy metal additive manufacturing system from AML3D.

The $400,000 3D printing unit will be used across a range of existing and new initiatives at UQ.

The Arcemy unit destined for Brisbane is a wire additive manufacturing (WAM) machine that can 3D print across a variety of metal alloys and allows up to 1.5m dimensions and 750 kg in mass.

According to Adelaide's AML3D the machine has an approximate deposition rate of up to 7-8 kgs/hour depending on the material being used.

AML3D managing director Andy Sales said: “We are thrilled to be able to supply UQ with what we believe is the world’s most sophisticated integrated wire-based 3D printing unit.

“There is an expectation that we will work closely with UQ in the future around specific R&D programs that will benefit both parties in research, industry application and students’ base learning and research.”

WAM printers have the advantage of being able to utilise a wide range of metal wires already certified for welding, making them significantly more flexible than powder-based printers.

AML3D will work with UQ in the installation and commissioning of the unit.

Picture: AML3D

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos