Unlocking lunar potential: Australia’s Big Dipper Challenge

Ben Sorensen explains the recently-launched Big Dipper Challenge, and its role as a doorway to the burgeoning space economy and its supply chain.

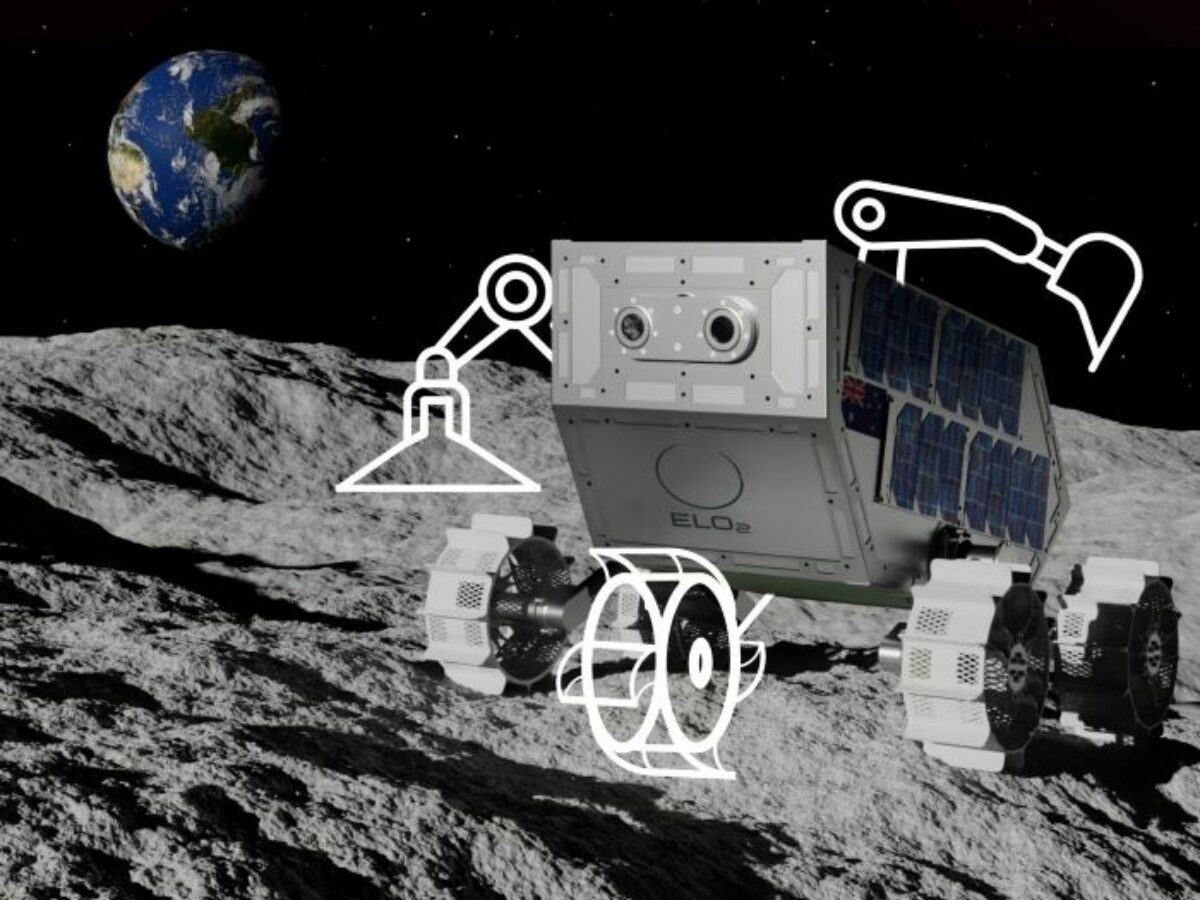

In a bold leap for the Australian manufacturing sector and space exploration, the ELO2 Consortium has launched the Big Dipper Lunar Regolith Acquisition Challenge, a national initiative designed to propel Australia and its engineering talents to the forefront of lunar exploration.

The challenge consists of two phases, with the first phase focusing on the design of a Regolith Sample Acquisition Device for the Australian-engineered ELO2 design lunar rover.

This rover is being designed to play a critical role in NASA’s Artemis programme, with a mission to collect and deposit lunar regolith at a NASA In-situ Resource Utilisation (ISRU) facility on the moon for oxygen extraction – a vital step in establishing a sustained human presence on the Moon.

The Importance of the Big Dipper Challenge to Australia

The Big Dipper Challenge represents a significant opportunity for the Australian public to contribute to a historical national effort while showcasing its ingenuity on the global stage. By participating, the public can have the potential for their design to be included in ELO2’s lunar rover design.

For the sovereign manufacturing industry in Australia, the Big Dipper Challenge is not just a competition but a doorway to the burgeoning space economy and its supply chains. Successful designs could lead to Australian-made components and systems being utilised in international space missions, enhancing the nation’s reputation in aerospace and defence manufacturing.

Phase 1: Designing for the Lunar Frontier

Participants are tasked with creating a device that is durable, repeatable, and scalable. It must fit a compact rover, capable of navigating the lunar terrain while withstanding harsh conditions such as extreme temperature fluctuations and abrasive lunar dust. The rover’s design constraints include a maximum mass of 20 kilograms, a stowed size limit, and solar-powered energy considerations.

Phase 2: Shaping Tomorrow’s Rovers

The second phase of the challenge involves distilling the insights from Phase 1 into actionable design recommendations for future rovers. These recommendations are expected to drive innovation in lunar resource acquisition and utilisation, informing the development of next-generation rovers capable of more extensive and complex missions.

Overcoming Lunar Challenges

The lunar environment poses unique challenges that must be considered. Lunar dust, gravity variances, and extreme temperature changes are just some of the hurdles that must be overcome. Participants will have to craft innovative solutions that are not only functional but also resilient against the Moon’s unforgiving environment.

The AUKUS Pillar II Opportunities

The challenge aligns with the goals of AUKUS Pillar II, opening avenues for the Australian manufacturing industry in areas of critical technologies and defence. There is potential for Australian industry to leverage this challenge to build capabilities in space and remote systems – a key area of interest for defence and exploration partnerships.

Participation and Collaboration

This challenge is an open invitation to all – from seasoned professionals to those keen to learn and develop skills in CAD and space engineering. Participants are required to submit a CAD design, answer submission form questions, and create a video explaining their concept in simple terms.

Australia’s Role in the Future of Space Exploration

The Big Dipper Challenge is more than a competition; it’s a step toward ensuring Australia’s role in the future of space exploration. Successful designs from this challenge could influence international standards for lunar exploration and set a precedent for Australian engineering excellence.

Conclusion

The Big Dipper Lunar Regolith Acquisition Challenge stands as a testament to Australia’s commitment to advancing its space capabilities. For the manufacturing sector, it presents an unprecedented chance to contribute to a vital aspect of space exploration, while also aligning with AUKUS Pillar II objectives to enhance Australia’s sovereign defence industry and technological prowess.

This project isn’t just about space; it’s about showing what Australian innovation can do and how it can benefit industries back on Earth. We’re not just investing in a mission; we’re investing in our future — and that’s something every Australian should be proud of.

The challenge is set – it is now up to Australia’s engineers, designers and the general public to embrace this opportunity, push the boundaries of what’s possible, and place Australia at the heart of the next giant leap for humankind. There is also the opportunity for the little kids to get involved by participating in the Little Dipper Challenge https://www.elo2.au/little-dipper-challenge.

Picture: supplied

Ben Sorensen is Director Innovation & Commercialisation, EPE Trusted to Protect.

Further reading

Call for ideas for a mechanical arm for a lunar rover

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos