UNSW experts create new hydrogel with promise in biomedical research

A new synthetic hydrogel developed by researchers at UNSW Sydney has a number of claimed benefits, with the team eager to explore its commercial potential as a substitute for animal-derived products.

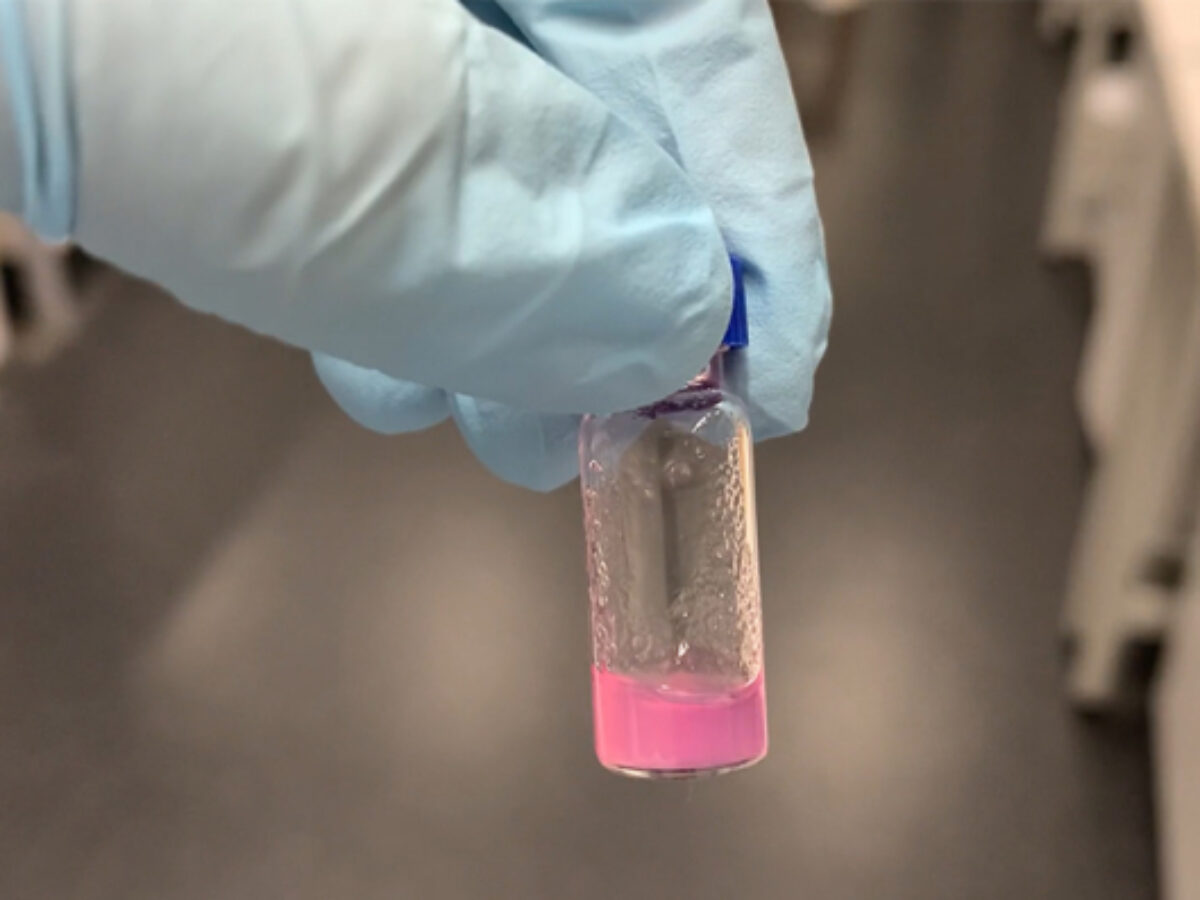

In a statement from the university, hydrogels are described as a family of substances that provide tissue such as seaweed and cartilage with their “squishy” nature, are able to mimic human tissue, and are used for purposes including growing human cells in a laboratory.

The new synthetic hydrogel was discovered by the study’s lead author, PhD student Ashley Nguyen, while examining computer simulations of self-assembling materials during a Covid lockdown. She said she “stumbled upon” tryptophan zippers: “short chains of amino acids with multiple tryptophans that act as a zipper to promote self-assembly, which have been dubbed ‘Trpzip’.”

“I was excited to identify a unique peptide sequence using computational simulations that might form a hydrogel,” said Nguyen, who sees the discovery as opening up potential to develop ethical replacements for animal-derived hydrogels.

“After we returned to the lab, I synthesised the top candidate and was thrilled to see it actually form a gel.”

She added that, “animal-derived materials are problematic for use in humans because of the negative immune response that occurs. With Trpzip, we have a synthetic material that not only shows potential in many areas where natural materials are currently used, but also could outperform them in others, such as clinical research.”

The research will progress to partnering with industry and clinical scientists to test Trpzip gels in tissue culture and explore applications suiting its properties.

As well as addressing lab-grown hydrogels’ failure to recreate human tissue, Trpzip is also antimicrobial, explained UNSW’s Associate Professor Kris Kilian.

“This combination lands it in the sweet spot for materials that might be useful in medicine,” Kilian said.

“The material is also self-healing, which means that it will reform after being squished, fractured, or after being expelled from a syringe. This makes it ideal for 3D bioprinting, or as an injectable material for medicine.”

Trpzip’s viability in a lab setting was tested against mouse tumour-derived Martigel as a culture of patient tissue.

The new material might one day answer the inconsistency and cost issues in Matrigel for biomedical researchers. Killian said if Trpzip hydrogels and similar materials could provide more uniform and cost-effective alternatives, this “would be a tremendous outcome if our material reduced the number of animals used in scientific research.”

Picture: credit UNSW

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos