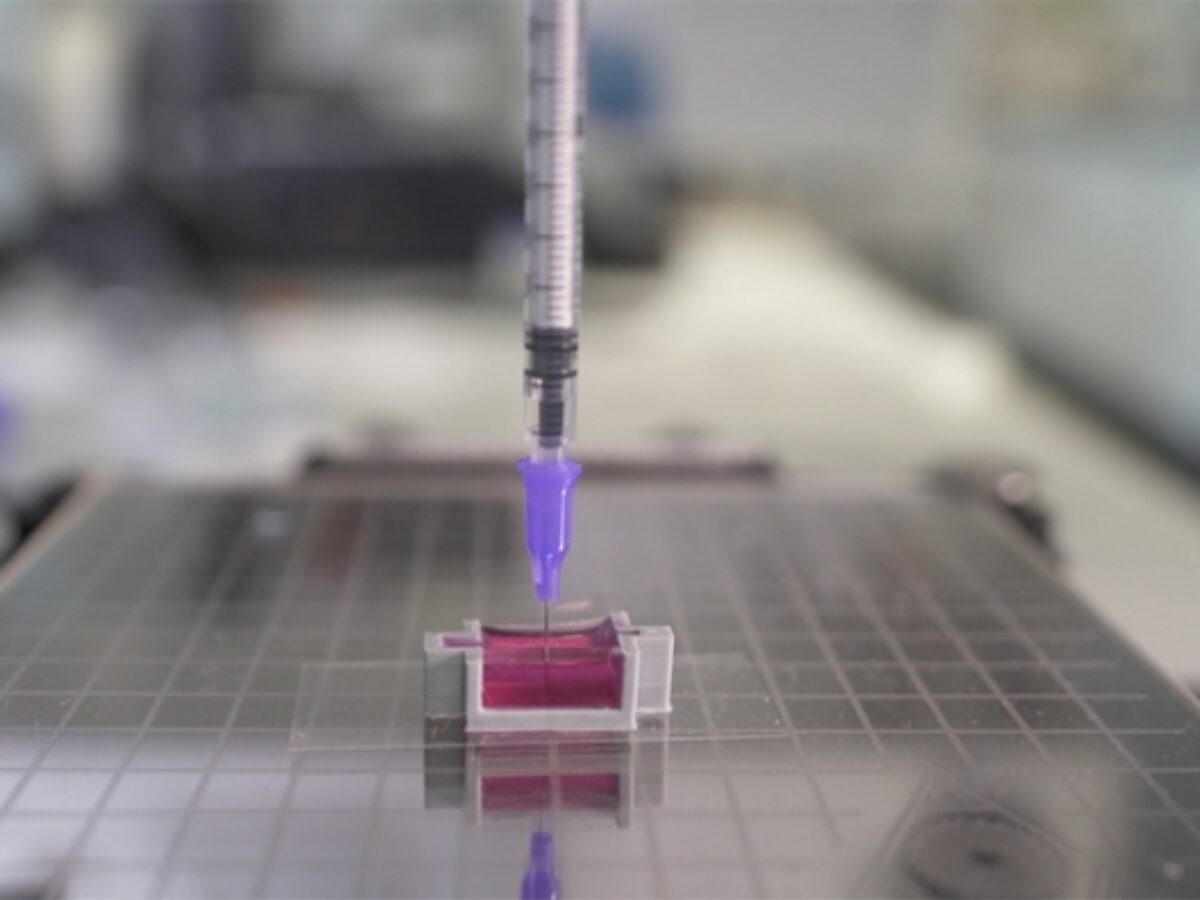

UNSW team 3D prints bone-like structures containing living cells

A University of NSW team has developed a ceramic-based ink allowing the creation of 3D printable bone-like structures with living cells.

The team calls its technique “ceramic omnidirectional bioprinting in cell-suspensions” or “COBICS”.

While it is not the first 3D printed material that mimics bone, it was the first that did not require harsh chemicals or radiation, said Dr Iman Roohani from the university's School of Chemistry. It could also be made at room temperature.

“This is a unique technology that can produce structures that closely mimic bone tissue,” he said in a statement on the work, published in Advanced Functional Materials.

“It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected.”

Associate Professor Kristopher Kilian said that previously you would have to use a furnace and toxic chemicals to make such a material for replacing bone.

“This produces a dry material that is then brought into a clinical setting or in a laboratory, where they wash it profusely and then add living cells to it,” said Kilian.

“The cool thing about our technique is you can just extrude it directly into a place where there are cells, like a cavity in a patient’s bone. We can go directly into the bone where there are cells, blood vessels and fat, and print a bone-like structure that already contains living cells, right in that area.”

The university said the next steps would be “in vivo tests in animal models to see if the living cells in the bone-like constructs continue to grow after being implanted in existing bone tissue.”

Picture: UNSW

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos