“We’ve only scratched the surface of the opportunity.” An interview with the new AFCG CEO about Geelong’s fibre future

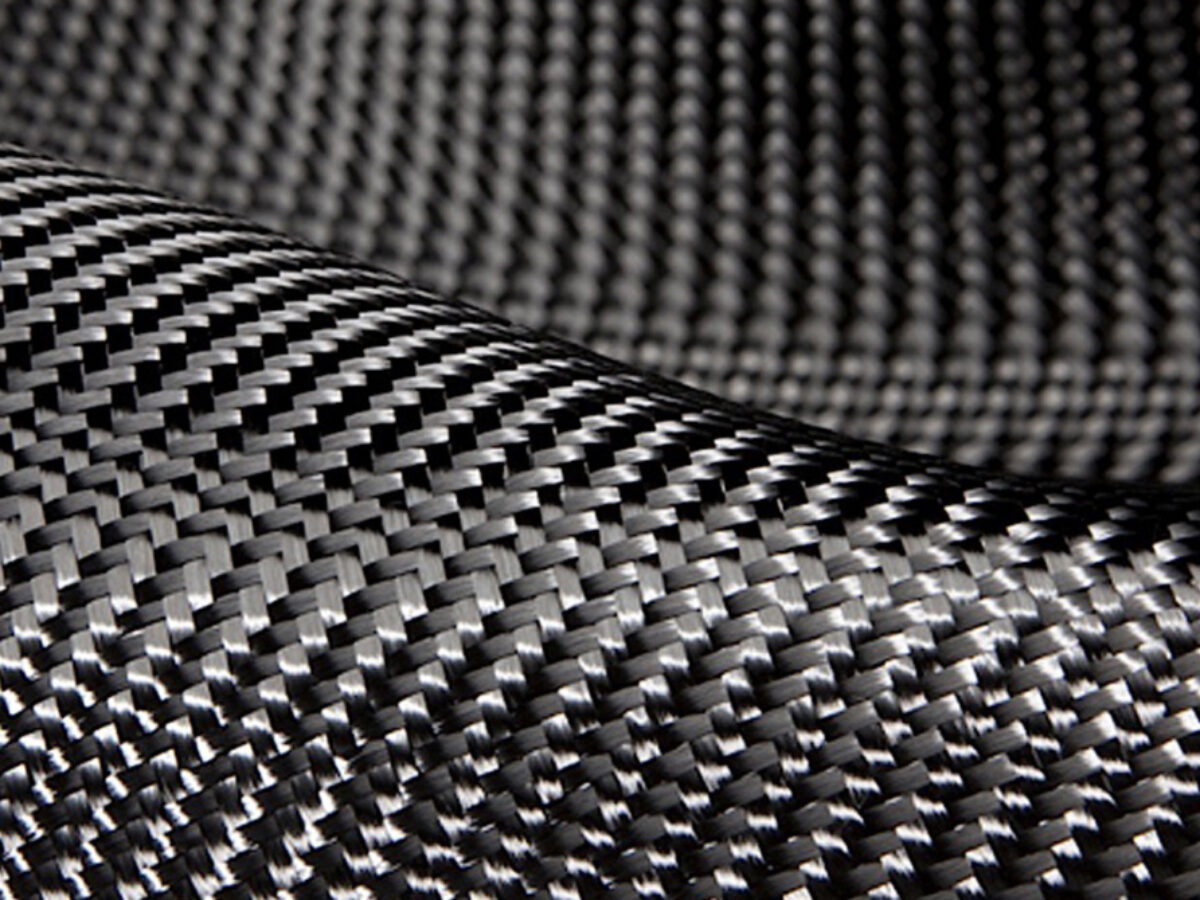

It is hard to think of carbon fibre in Australia and not think of Geelong. It’s a material with countless uses – in cars, sporting goods, exoskeletons and beyond – and Victoria’s second city is home to the scientific, engineering and commercial expertise needed to develop it into the products of tomorrow.

The Advanced Fibre Cluster is one effort to maximise the potential of this expertise. Brent Balinski spoke to its recently-appointed CEO, Jennifer Conley, about the benefits of collaborating, the group’s plans, its membership, and some of the cutting-edge fibre projects underway.

@AuManufacturing: What is the story of the Advanced Fibre Cluster Geelong so far? Please give a potted history of the initiative.

Jennifer Conley: The Advanced Fibre Cluster grew in an organic way over more than a decade around Deakin University and a small group of innovative companies working to develop products made with carbon fibre. When Deakin launched the Carbon Nexus facility in 2014 – unique in the world in terms of its open-access carbon fibre and composite research – collaboration within the cluster was boosted. So, the current members have been challenging one another and learning from one another, and working together on a variety of projects for 10 years and some of them much longer. Essentially they knew that collaborative research and knowledge sharing was good for each of them and they are a group of people who see a new strong future for high value manufacturing. In 2015, with support from a Victorian Government program through the Geelong Manufacturing Council, they began the process of being more strategic, developing the advanced fibre sector for Geelong and the region. My role came about because of that hard work and that strategy. It is a strategy which recognises that sustained competitiveness comes about because of dynamic knowledge creation and collaboration. People here could see that this geographical region of knowledge development and creativity was producing bigger returns on innovation.

@AuManufacturing: Why is it an interesting time to be involved in advanced fibres in Geelong? What’s exciting about a) this new role and b) working with manufacturing again?

Jennifer Conley: I do love working with Australian innovators, people with foresight who challenge the status quo. These are entrepreneurs and inventors, and inspirational people who plan for huge possibilities like being part of the global mobility revolution – supplying electric vehicles or urban air mobility – as well as developments in aerospace and the emerging space sector, the stuff of Blade Runner. Advanced fibres can be ultra strong, lightweight and even intelligent, and they are an important part of the future for new modes of transport as well as new assistive and wearable technologies that augment the body’s natural physical abilities. Carbon fibre, for example, is being used in the design of exoskeletons for factory workers in heavy industries and for new generation devices to make life easier for people with disabilities. These are projects I can see our WorkSafe and NDIA colleagues in Geelong being interested in. Advanced fibre technologies open the door to innovative solutions because they are lightweight, strong and adaptable. As far as working in manufacturing again, I admire the incredible passion of small and medium enterprise owners for making things and especially making for export, and I have a huge amount of respect for their commitment to their employees and communities. Manufacturing’s contribution to our economy and to society is enormous.

@AuManufacturing: What is your membership at currently? Who is involved?

@AuManufacturing: What is your membership at currently? Who is involved?

Jennifer Conley: The founding group that launched the current phase of the cluster (in Feb this year) includes Carbon Revolution, Austeng, Quickstep, Sykes Racing, Andritz Fabrics and Rolls (formerly Xerium Technologies), Geelong Orthotics, Industrial Control Technology (ICT), Carbon Nexus, the City of Greater Geelong and Geelong Manufacturing Council.

@AuManufacturing: How will the cluster assist Geelong manufacturers? Will it involve grants around collaborative projects? Collaborative tendering? Opportunities to share equipment and other resources? A little information on this for readers, please.

Jennifer Conley: Technology is developing at a speed humanity has never seen before – which adds a certain level of pressure to businesses wanting to remain relevant! The forward-looking ones genuinely regard collaboration from an “enlightened self-interest” point of view. Clustered industries overseas have been shown to grow 14 per cent faster than non-clustered industries. You get a rapid diffusion of best practices, and individuals sharing knowledge and witnessing others’ success are motivated and challenged. The Advanced Fibre Cluster has already generated a number of collaborative projects, for example a project between Sykes Racing, Carbon Revolution and Carbon Nexus, through a grant from the AMGC, to address a global challenge for composite manufacturers around resin shrinkage. I will be creating systems for sharing business and research opportunities and building on the inter-firm networks we have here. We’ve only scratched the surface of the opportunity. It is about the cluster growing and continuing to work together and about helping to make that happen more smoothly, more easily.

@AuManufacturing: I noticed some interesting work involving Austeng, Rocla, Carbon Nexus and others last year, which led to carbon fibre-reinforced geopolymer bridges. Do you think building materials are an area where your members could tap into new opportunities?

Jennifer Conley: Concrete cancer and the degradation of wooden structures are major issues for local government everywhere and the Austeng-led project triples the life-span for pedestrian bridges. Carbon fibre reinforced geopolymer concrete has big potential for the entire building and construction industry.There will be more about that later this year.

@AuManufacturing: Is the cluster purely to do with carbon fibre, or are other businesses working with advanced fibres (e.g. Cytomatrix) welcome to be a part of the cluster and its work?

Jennifer Conley: While the cluster initially grew around carbon fibre activities, it is about advanced fibres generally and definitely not limited to carbon fibre.

There are advanced materials being commercialised for use in stem cell research, and intelligent materials like geotextiles which help prevent leaching in mine tailings dams. The cluster will also be about finding opportunities and building on some of the work Deakin and companies in the region are already doing in future fibres. Cytomatrix is a great story of translating research success around short polymer fibres, ultimately for use in the scaffolds used for stem cell research, into commercial scale success.

@AuManufacturing: You were a part of the Australian Advanced Manufacturing Council for several years, before finishing up as its executive director in 2017. Do you have anything to say about the appreciation of “advanced manufacturing” as a concept in Australia over the years?

Jennifer Conley: I think we’ve seen a quantum leap in understanding about what the opportunity is for Australia in recent years – and what the capabilities are and can be for Australian manufacturing. The term “advanced” encapsulates the whole ecosystem of a highly skilled workforce, stable and open government and a sophisticated research sector engaged with innovative companies with a global orientation. We generally can’t compete in lower value manufacturing in any case, and quite rightly want to maintain our standard of living. We have an increasing number of homegrown success stories to prove the naysayers wrong.

For your readers, I encourage them to get in touch if they would like more information or would like to participate in the cluster. Email: jennifer.conley@advancedfibrecluster.org.au .

Subscribe to our free @AuManufacturing newsletter here.

Picture: www.turnology.com

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos