2023 will decide if the Calix process can unlock zero emission steel

Steel makers are looking towards net zero with hydrogen produced from renewable sources the world's best bet on decarbonising this essential industry. Here, in an article adapted from ARENA, we look at the ARENA project that will decide the fate of Calix's Zesty steelmaking technology as early as this year.

The basic oxygen steelmaking process is one of those century-plus old technologies that has stood the test of time.

Developed for another age when burning coal was seen almost as a social good, coal provides the fuel, the chemistry and the physical environment for turning iron ore into iron metal.

Electric arc furnaces are a lower emissions alternative, but the use of gas to produce direct reduced iron (DRI) feedstock (scrap metal is another alternative), means the process still emits around 0.7 tonnes of CO2 per tonne of steel.

The Australian Renewable Energy Agency and Victorian industrial process company Calix will complete a research programme in 2023 which utilises hydrogen rather than fossil fuel as the reductant – the hydrogen reacting with iron ore to produce iron and water.

Hydrogen produced by electrolysis using renewable energy has the potential to eliminate natural gas altogether from the steelmaking value chain.

ARENA is providing $947,035 in funding to Calix to examine its potential low emission iron ore processing technology, with the total pre-Front End Engineering and Design (FEED) study costing $1.96 million.

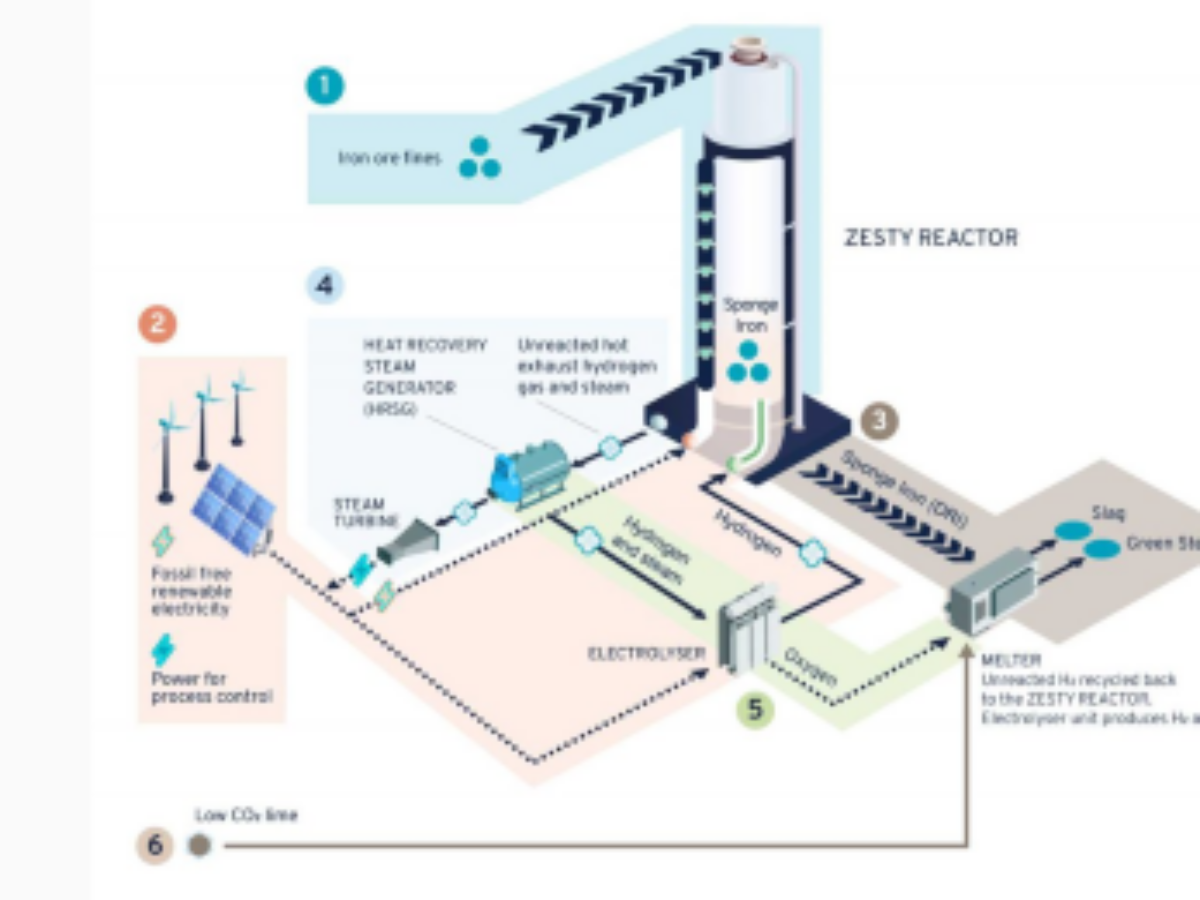

It will evaluate the feasibility of using Calix’s proprietary Zero Emissions Steel Technology, nicknamed ZESTY (main illustration), to produce zero-emissions iron feedstock suitable for use in electric arc furnaces. Powering electric arc furnaces with renewables removes fossil fuels from the value chain.

Calix’s proposed demonstration plant will be capable of producing 30,000 tonnes each year of the feedstock material known as Hydrogen Direct Reduced Iron (HDRI).

To achieve that, ZESTY claims two advantages: it operates at temperatures approximately 1,000 C below blast furnaces, and it requires less hydrogen to convert the iron ore into iron.

ARENA CEO Darren Miller said ZESTY is a prime example of Australian innovation helping tackle global challenges.

Miller said: “Decarbonising heavy industries like steel is both a big challenge and a big opportunity. ARENA is always looking to support companies like Calix that are developing potential solutions.

“With abundant renewable energy resources and the world’s largest iron ore deposits, we have a unique opportunity to decarbonise an industry that is critical to the global economy.

“We’re looking forward to the outcomes of this study and hope to see ZESTY play an important role in the future of Australian iron and steel.”

Calix Managing Director and CEO, Phil Hodgson (pictured below) said the project aims to further develop a homegrown Australian technology.

Hodgson said: “The decarbonisation of iron and steel represents a unique opportunity for Australia.

“This project aims to further develop a homegrown Australian technology that we believe, together with Australia’s leading iron ore and renewable energy resources, can help make Australia a leading exporter of not just iron ore, but green iron and green steel.”

The study is due to be completed in late 2023, informing Calix’s decision whether to proceed with the demonstration plant.

Further reading:

A NEW DEAL PLAN FOR MANUFACTURING – SUPPORT FOR LOCAL INNOVATION IS CRUCIAL FOR AUSTRALIA’S MANUFACTURING FUTURE

CALIX LOW EMISSIONS CEMENT TECHNOLOGY GETS GREEN LIGHT

Picture: Calix/Zesty process/CEO Phil Hodgson

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos