Fortescue opens Gladstone electrolyser facility

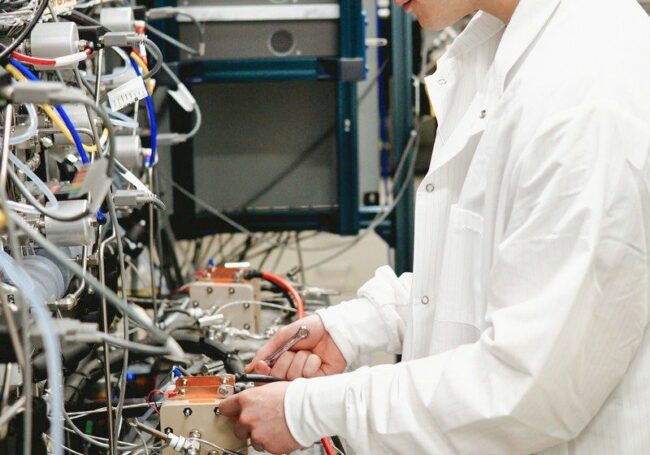

Mining and green technology manufacturer Fortescue has officially opened its electrolyser manufacturing facility in Gladstone, Queensland – one of the first globally to house an automated assembly line (pictured). The 15,000sqm advanced manufacturing facility, constructed in just over two years, will have capacity to produce over 2GW of Proton Exchange Membrane (PEM) electrolyser stacks annually.…