Alpha HPA to move downstream to synthetic sapphire

Aluminium materials manufacturer Alpha HPA is to move to downstream processing to produce synthetic sapphire from high purity alumina (HPA) sourced from its refinery at Gladstone, Queensland.

Stage One Precursor Production Facility (PPF) in Gladstone is now in operation, producing 99.999 per cent high purity alumina (HPA) coating pre-cursor material for use in manufacturing lithium-ion batteries.

From 2025 the plant will be capable of producing 10,000 tonnes of HPA equivalent per year.

Now its subsidiary, Alpha Sapphire has agreed to terms with the QIC Minerals and Battery Technology Fund (QCMBTF) for up to $30 million to accelerate the roll-out of an initial 50 sapphire growth units at its Gladstone operation.

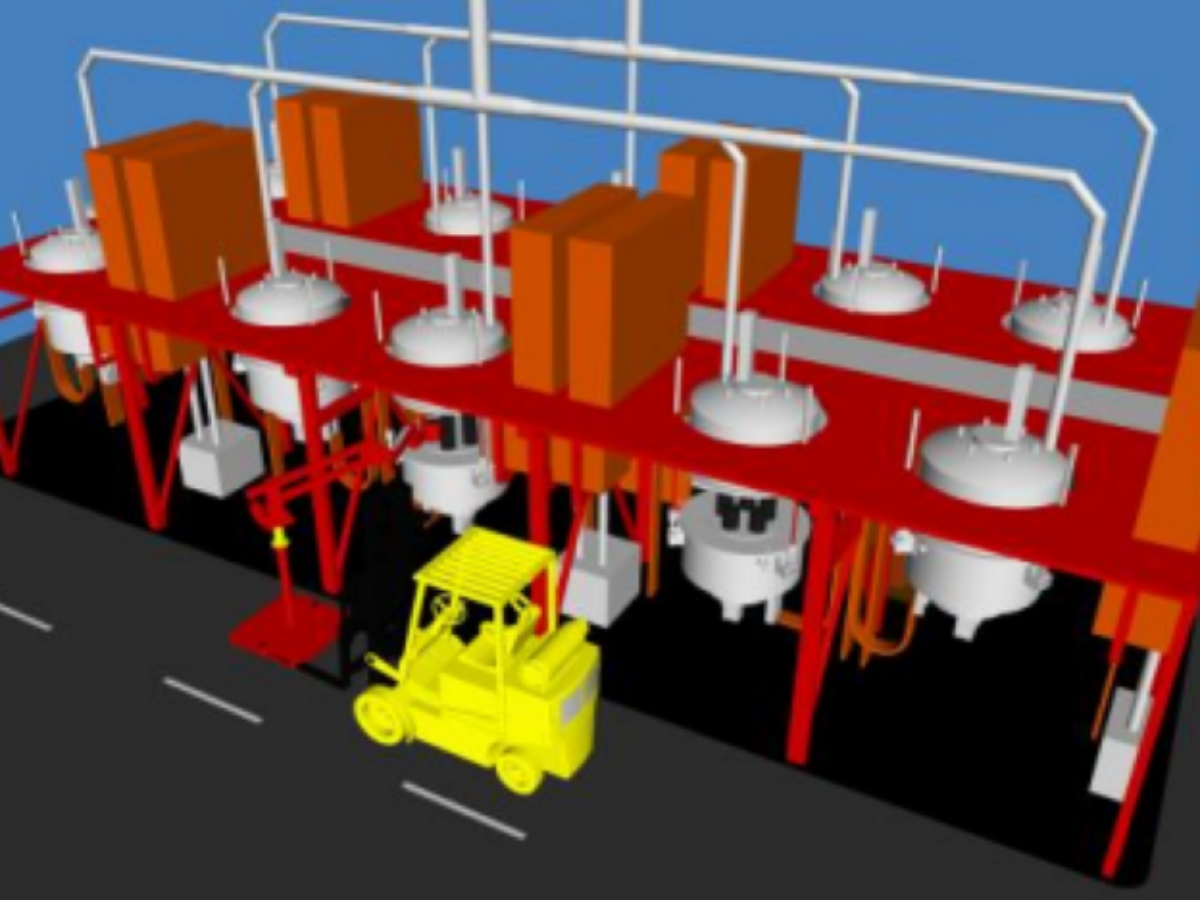

The growth units utilise crystal growth technology from partner Ebner Industrieofenbau GmbH and Famtech GmbH allowing the company to enter the downstream production of synthetic sapphire glass for the LED and optics markets.

$3 million of the Queensland funding will reimburse Alpha Sapphire for an initial two sapphire growth units, with further funds payable on the rollout of an additional 48 growth units.

Alpha Managing Director Rimas Kairaitis said “Alpha is deloighted to have reached agreement with QIC on funding for Alpha Sapphire and for the broader support from QIC and the Queensland Government to support private sector investment to add value via downstream processing of Queensland materials.”

Ultimately Alpha Sapphire envisages installing 1,000 synthetic sapphire growth units which would consume up to 4,000 tonnes of HPA per annum.

Further reading:

Alpha HPA manufactures high purity alumina

Main picture: Commercial module of 10 growth units

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos