AML3D continues oil and gas focus with order for record-breaking pressure vessel

AML3D has announced a $190,000 order from ExxonMobil Asia Pacific that will see the Adelaide company create the world’s biggest additively manufactured commercial pressure vessel, to be used at a refinery.

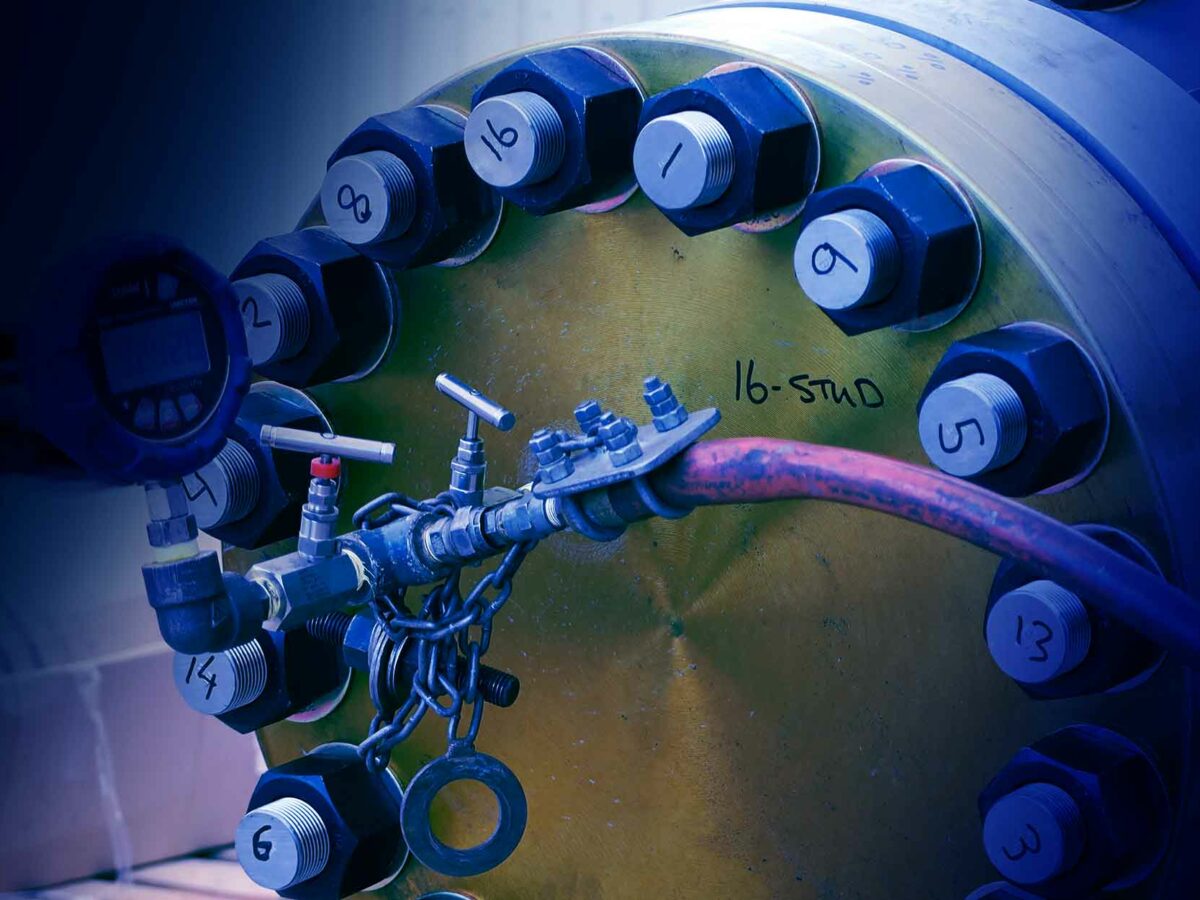

In a statement on Wednesday, AML3D said the eight-tonne vessel would be 8 metres long and about 1.5 metres in diameter, and made out of “a high strength wire feed stock of > 450 MPa yield strength” using the company’s WAM process.

The vessel would use five of the company’s eight proprietary Arcemy machines, which use wire arc welding-based AM to create freeform parts out of metal wire. It will be delivered to meet a September deadline – “around 12 weeks as opposed to a 12 month lead time” – the company said.

Testing would include “hydrostatic pressure tests, full x-ray testing and visual inspection by 3rd party” said AML3D, “verified for compliance to ASME VIII” and also follow “the new global [American Petroleum Institute’s] 20S Standard for “Additively Manufactured Metallic Components for Oil & Gas components”.

“We have a major focus on building our capability and presence in the global Oil and Gas sector as an immediate value driver for the business and this contract absolutely aligns with that objective,” said Managing Director Andy Sales.

“It is also pleasing to note that during discussions with ExxonMobil the advantages of AML3D’s technology over traditional manufacturing were a key consideration.”

The news follows the company’s announcement in November that it had printed a 940 kilogram monocoque piping spool component, which it said was the world’s largest additively manufactured metal oil and gas piping component. This was also printed according to API 20S Standard.

Picture: AML3D

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos