Brisbane team creates world-first 3D printed chest implant

A team led by Queensland University of Technology’s Distinguished Professor Dietmar W Hutmacher has created an implant to help a young student suffering from “funnel chest.”

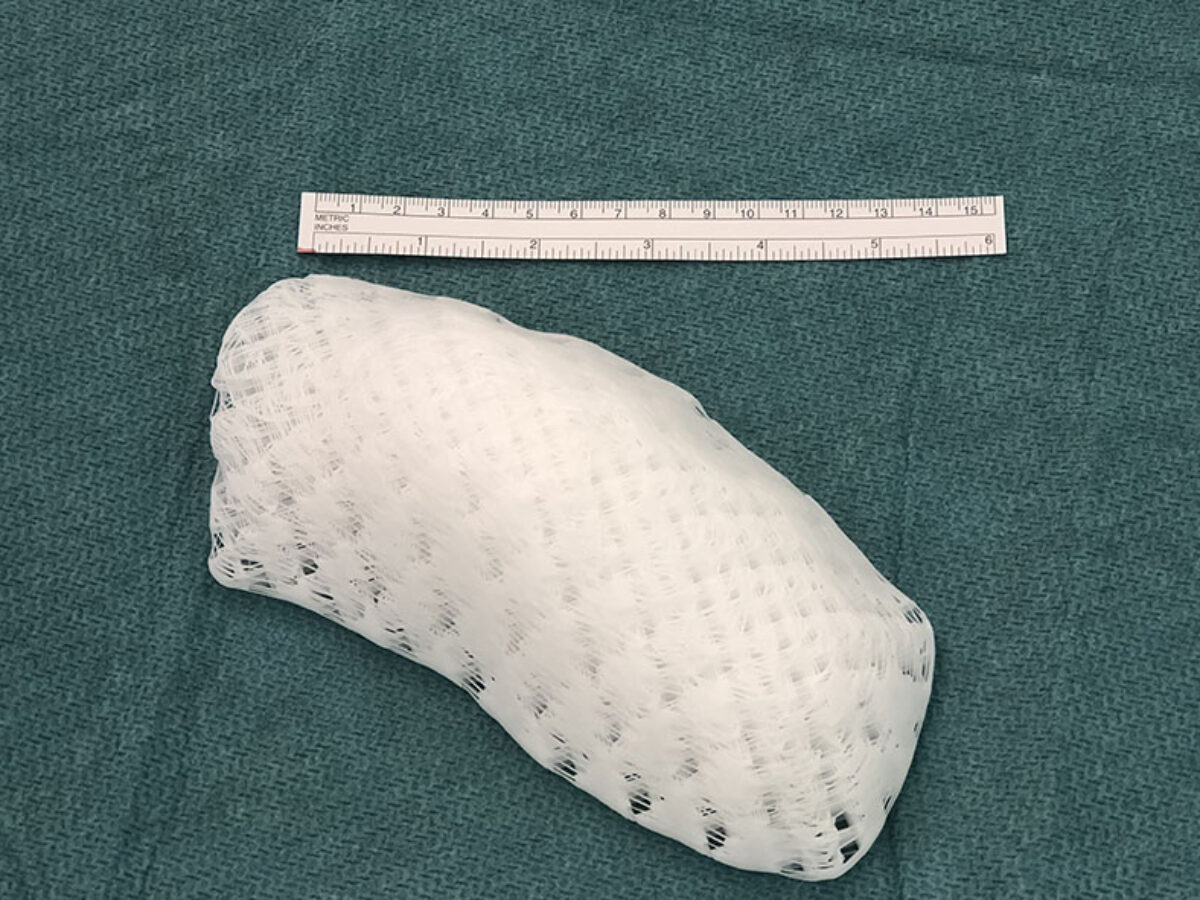

The implant was made of a porous, biodegradable substance, printed to be specific to the patient’s chest. The scaffold of this was injected with the patient’s own fat during the time of insertion, said surgeon Dr Michael Wagels, “to commence the reconstruction/regeneration of the highly porous scaffold with more than 90 per cent of her own tissue.”

Hutmacher — who heads the ARC Industrial Transformation Centre in Additive Biomanufacturing and is a long-time collaborator with Wagels — said the implant was tailored to fit neatly over the chest deformity, allowing blood vessels and fat to grow into it and lead to a normal-shaped chest.

(Funnel chest or sunken chest is a birth defect where the sternum and ribs grow inward.)

“The implant had to be flexible as the chest is in constant movement and so it had to have the ability to change shape without breaking,” said Hutmacher, a regenerative medicine specialist.

“The implant was made to fit precisely over the chest deformity to allow the patient’s own blood vessels and fat tissue to grow into the implant to create a lasting normal shaped chest.

The interdisciplinary effort featured input from clinicians at Princess Alexandra Hospital, Translational Research Institute (TRI), Australian Centre for Complex Integrated Surgical Solutions (ACCISS), ARC ITTC in Additive Biomanufacturing and the printing of the patient-specific scaffold by German company BellaSeno GmbH.

Picture: QUT

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos